Pervious concrete for pavements and preparation process thereof

A permeable concrete and cement technology, applied in the field of concrete, can solve the problems of large deformation, short service life, low strength of permeable concrete, etc., and achieve the effect of prolonging service life, improving early strength and middle and late strength, and good compression resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0036] A modified bentonite, prepared by the following method:

[0037] a. bentonite pulverization liquid preparation: pulverize bentonite through a 120-mesh sieve, add water with 5 times the quality of itself, and stir to obtain bentonite solution;

[0038] b. Preparation of modified solution: crush sodium titanate and ash powder at a mass ratio of 1:1, pass through a 100-mesh sieve, and soak in hydrogen peroxide at 60°C whose weight is three times its own weight for 3 hours to obtain modified liquid;

[0039] c. Bentonite modification: add the bentonite solution obtained in step a to the modified liquid obtained in step b, stir at 50°C for 1 hour, then add dehydrated castor oil and ultrasonically disperse at 50°C for 30 minutes, then Stir in an environment of ℃ until it is completely dry to obtain modified bentonite.

Embodiment 1

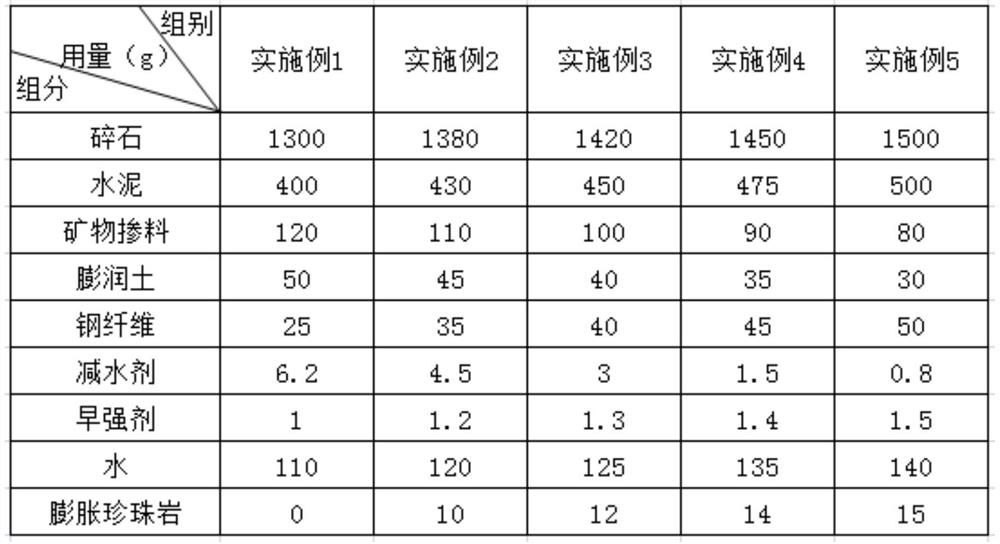

[0041] A kind of permeable concrete for pavement, its component content is shown in Table 1.

[0042] Table 1 embodiment 1-5 component content table

[0043]

[0044] Among them, the particle size range of gravel is 15-25mm.

[0045] Bentonite is a powder whose particle size meets a 120-mesh sieve.

[0046] The mineral admixture is mineral powder.

[0047] The early strengthening agent is triethanolamine.

[0048] This embodiment also provides the preparation process of the above-mentioned permeable concrete for pavement, including the following steps: S1. Powder premixing: uniformly mix cement, mineral admixtures, and bentonite to obtain premixed powder;

[0049] S2. Aggregate and powder blending: Add steel fibers to the gravel, stir and disperse evenly, then add the premixed powder obtained in step S1, disperse evenly, and obtain a blend;

[0050] S3. Concrete mixing: Add water, water reducer, and early strength agent to the blend obtained in step S2, stir and dispers...

Embodiment 2

[0052]A kind of permeable concrete for pavement, its component content is shown in Table 1.

[0053] Among them, the particle size range of gravel is 5-10mm.

[0054] Bentonite is a powder whose particle size meets a 120-mesh sieve.

[0055] The mineral admixture is a mixture of silica fume and ultrafine metakaolin at a mass ratio of 2:1.

[0056] The early strengthening agent is calcium formate.

[0057] This embodiment also provides the preparation process of the above-mentioned permeable concrete for pavement, including the following steps: S1. Powder premixing: uniformly mix cement, mineral admixtures, bentonite, and expanded perlite to obtain premixed powder; S2. Aggregate and powder blending: Add steel fibers to the gravel, stir and disperse evenly, then add the premixed powder obtained in step S1, disperse evenly, and obtain a blend;

[0058] S3. Concrete mixing: Add water, water reducer, and early strength agent to the blend obtained in step S2, stir and disperse ev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com