Degradable environment-friendly plastic and preparation method thereof

An environmentally friendly plastic and environmentally friendly technology, applied in the field of degradable environmentally friendly plastics and their preparation, can solve the problems of large waste volume, white pollution, and difficulty in degradation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

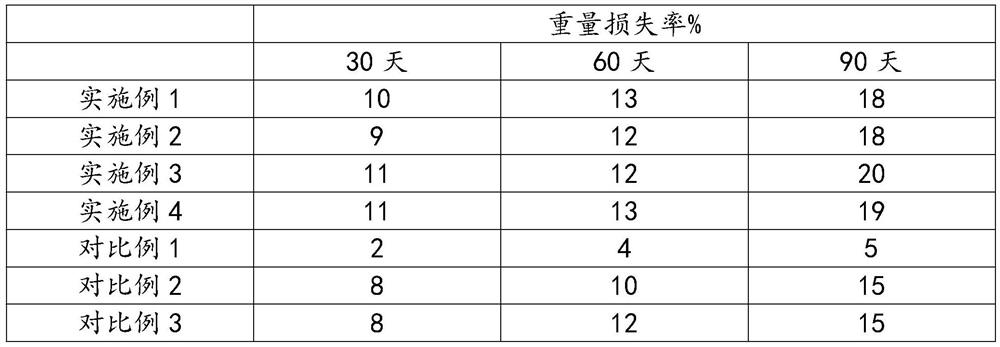

Examples

Embodiment 1

[0029] A degradable environmentally friendly plastic, comprising the following raw materials in parts by weight: 35 parts of environmentally friendly composite emulsion, 30 parts of degradable PVA, 20 parts of polylactic acid resin, 0.5 part of zinc stearate, and 1 part of methyl methacrylate-maleic anhydride;

[0030] The degradable environmentally friendly plastic is made by the following method:

[0031]Environmentally friendly composite emulsion, degradable PVA, polylactic acid resin, zinc stearate and methyl methacrylate-maleic anhydride were added to the mixer in sequence, and stirred for 45 minutes at a speed of 500r / min to obtain a mixture, and then Add the mixture into the twin-screw extruder, control the temperature of the first stage of the twin-screw extruder to 140°C, the temperature of the second stage to 160°C, the temperature of the third stage to 180°C, and the temperature of the die head to be 200°C. Produce degradable and environmentally friendly plastics. ...

Embodiment 2

[0040] A degradable environmentally friendly plastic, comprising the following raw materials in parts by weight: 40 parts of environmentally friendly composite emulsion, 35 parts of degradable PVA, 22 parts of polylactic acid resin, 0.8 part of zinc stearate, 2 parts of methyl methacrylate-maleic anhydride;

[0041] The degradable environmentally friendly plastic is made by the following method:

[0042] Environmentally friendly composite emulsion, degradable PVA, polylactic acid resin, zinc stearate and methyl methacrylate-maleic anhydride were added to the mixer in sequence, and stirred for 45 minutes at a speed of 500r / min to obtain a mixture, and then Add the mixture into the twin-screw extruder, control the temperature of the first stage of the twin-screw extruder to 140°C, the temperature of the second stage to 160°C, the temperature of the third stage to 180°C, and the temperature of the die head to be 200°C. Produce degradable and environmentally friendly plastics.

...

Embodiment 3

[0051] A degradable environmentally friendly plastic, comprising the following raw materials in parts by weight: 45 parts of environmentally friendly composite emulsion, 40 parts of degradable PVA, 26 parts of polylactic acid resin, 0.8 part of zinc stearate, and 2 parts of methyl methacrylate-maleic anhydride;

[0052] The degradable environmentally friendly plastic is made by the following method:

[0053] Environmentally friendly composite emulsion, degradable PVA, polylactic acid resin, zinc stearate and methyl methacrylate-maleic anhydride were added to the mixer in sequence, and stirred for 45 minutes at a speed of 500r / min to obtain a mixture, and then Add the mixture into the twin-screw extruder, control the temperature of the first stage of the twin-screw extruder to 140°C, the temperature of the second stage to 160°C, the temperature of the third stage to 180°C, and the temperature of the die head to be 200°C. Produce degradable and environmentally friendly plastics....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com