Water-based heat-insulating inorganic coating and preparation method thereof

An inorganic coating, water-based technology, applied in the direction of fireproof coatings, reflective/signal coatings, alkali metal silicate coatings, etc., can solve the problems of easy chalking and cracking, short service life, poor weather resistance, etc., and achieve improved stability, Good fire resistance, balanced effect of stability and reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

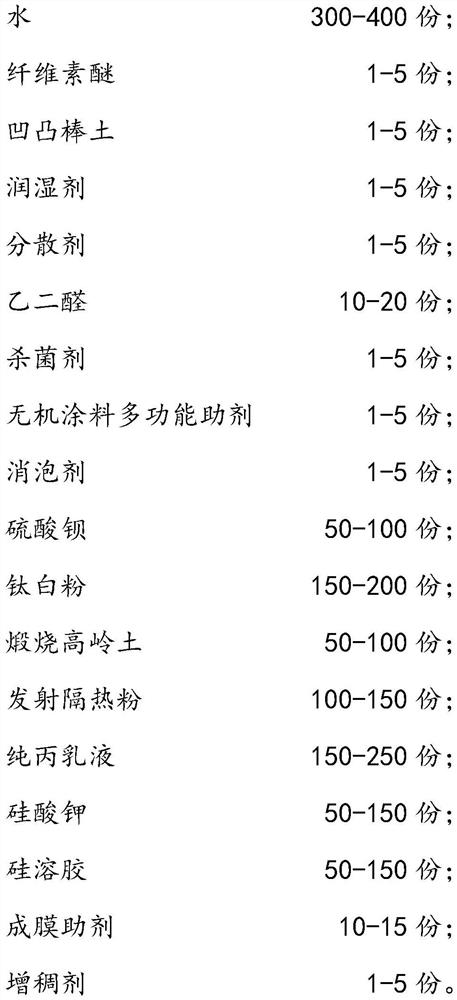

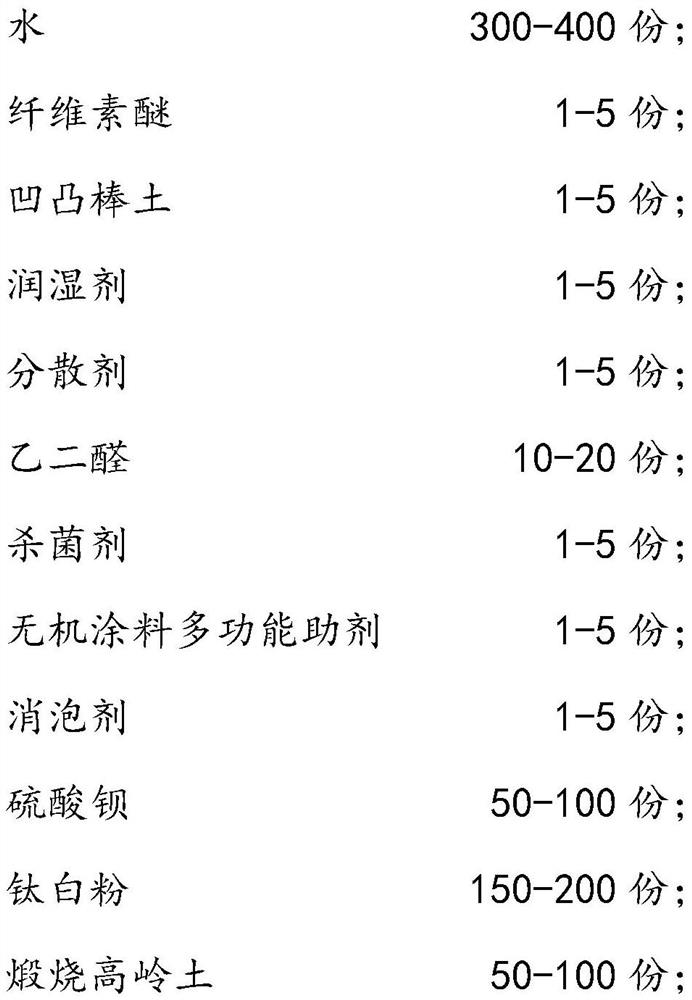

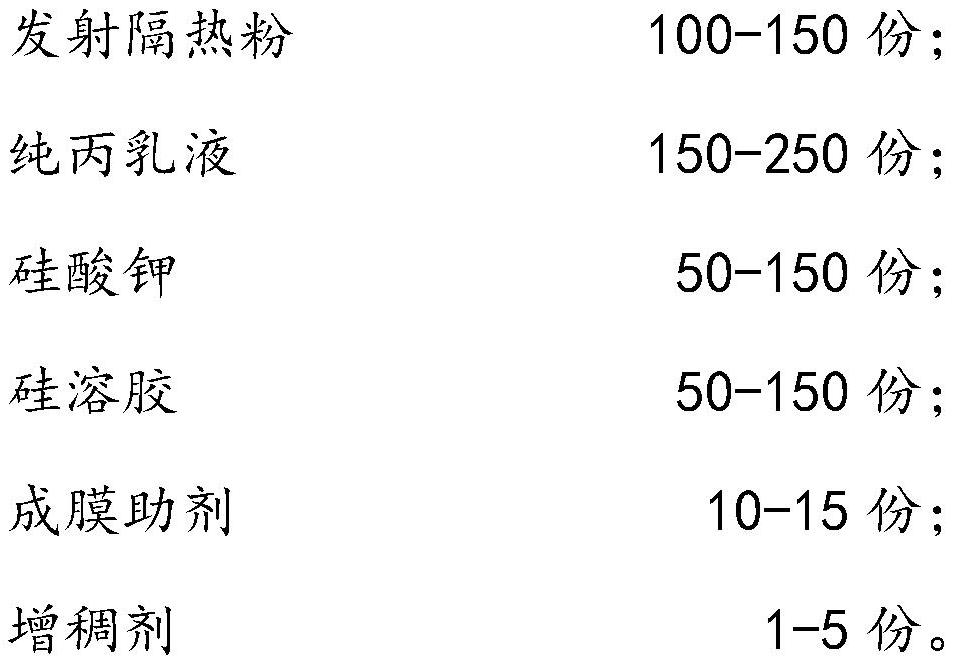

Method used

Image

Examples

Embodiment 1

[0040] Step 1. In the state of stirring, mix 200 parts of deionized water and 100 parts of emission heat insulation powder, and continue to stir until uniform, to obtain a mixture of emission heat insulation powder. The speed of the mixer is 500r / min, and the stirring time is 15min;

[0041] Step 2. In the state of stirring, add 2 parts of cellulose ether, 2 parts of attapulgite, 4 parts of dispersant, and 4 parts of wetting agent to the mixed solution of the emission heat insulation powder in step 1, and stir evenly to obtain the dispersion liquid. Speed 500r / min, stirring time 10min;

[0042] Step 3: Add 50 parts of barium sulfate, 150 parts of titanium dioxide, 50 parts of calcined kaolin, 1 part of cellulose ether, 10 parts of glyoxal, 200 parts of pure acrylic emulsion, 1 part of defoamer, stir evenly to obtain a stable solution, the mixer speed is 1200r / min, and the stirring time is 40min;

[0043] Step 4. In the state of stirring, add 2 parts of fungicides, 2 parts o...

Embodiment 2

[0046] Step 1. In the state of stirring, mix 200 parts of deionized water and 120 parts of emission heat insulation powder, and continue to stir until uniform, to obtain a mixture of emission heat insulation powder. The speed of the mixer is 500r / min, and the stirring time is 15min;

[0047] Step 2. In the state of stirring, add 3 parts of cellulose ether, 3 parts of attapulgite, 2 parts of dispersant, and 2 parts of wetting agent to the mixed solution of the emission heat insulation powder in step 1, and stir evenly to obtain the dispersion liquid. Speed 500r / min, stirring time 10min;

[0048] Step 3, under stirring, add 60 parts of barium sulfate, 160 parts of titanium dioxide, 70 parts of calcined kaolin, 2 parts of cellulose ether, 20 parts of glyoxal, 250 parts of pure acrylic emulsion, 3 parts of the dispersion liquid in step 2 part of defoamer, stir evenly to obtain a stable solution, the mixer speed is 1200r / min, and the stirring time is 40min;

[0049] Step 4. In t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com