Mask material capable of inactivating viruses and production line and application thereof

A production line and virus technology, applied in the field of mask materials that can inactivate viruses, can solve problems such as difficulties in the manufacture of meltblown cloth, and achieve the effect of ensuring adhesion, ensuring uniformity, and a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

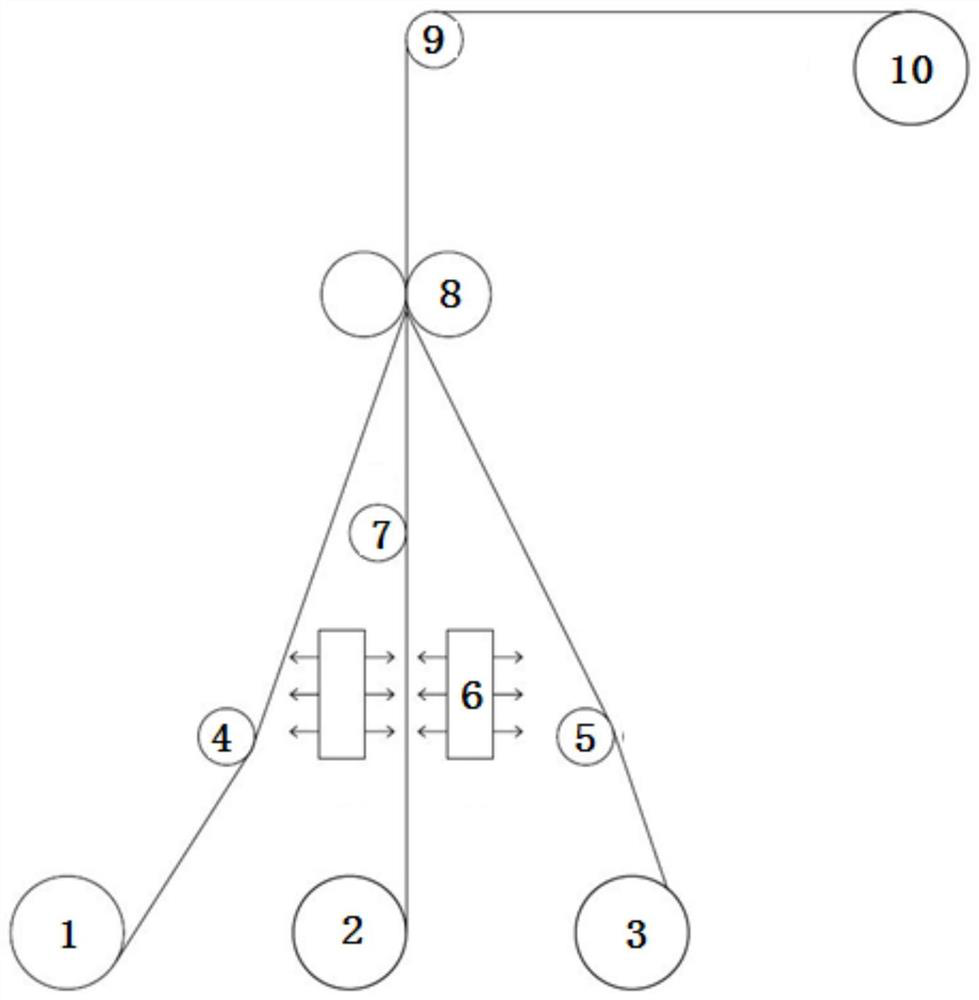

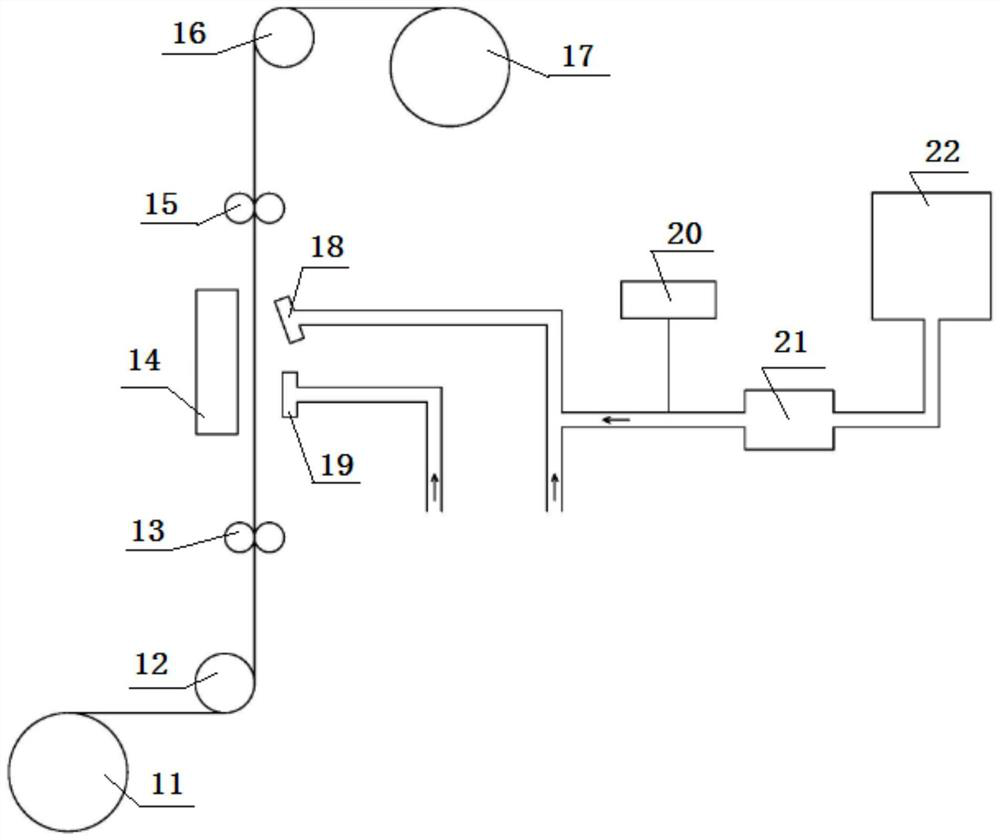

[0044] This embodiment discloses a mask material production line capable of inactivating viruses, its structure is as follows: figure 1 As shown, it includes a melt-blown cloth feeding unit, a low-temperature pressure roller 8, a receiving unit 10, a first non-woven fabric feeding unit, a second non-woven fabric feeding unit, two high-temperature gas generating units 6 and a melt-blown cloth production device, The meltblown cloth outlet of the meltblown cloth production device is connected with the inlet of the meltblown cloth feeding unit; the meltblown cloth feeding unit and the two non-woven fabric feeding units are located at the front end of the production line for conveying and heating the meltblown cloth and non-woven fabrics Woven fabric, the low-temperature pressure roller 8 is located at the middle end of the production line, and is used to compress two layers of non-woven fabrics and melt-blown fabrics, and the receiving unit 10 is located at the rear end of the prod...

Embodiment 2

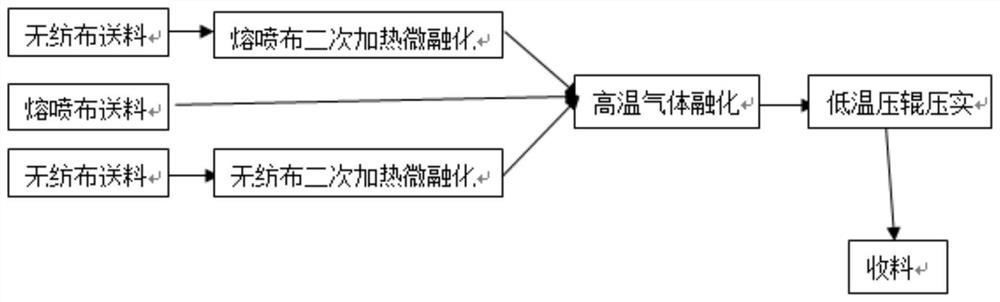

[0053] Adopt the mask material production line that can inactivate virus described in embodiment 1 to prepare the mask material that can inactivate virus, comprise the following steps:

[0054] Step 1. Mix the virus-inactivating powder with water and heat to generate high-temperature steam; the mass ratio of the virus-inactivating powder to water in step 1 is 1:3. The powder that can inactivate the virus described in step 1 includes but is not limited to the powder that can inactivate the new coronavirus, preferably a porous solid material for inactivating the virus produced by the Institute of Chemistry and Physics, Chinese Academy of Sciences, the publication number CN1552454A, a kind for Porous solid material for adsorbing and inactivating viruses and its application. The true diameter of the novel coronavirus inactivated particles is 5-10 μm. The specific gravity is close to that of water, insoluble in water, melting temperature above 1000°C, non-toxic, tasteless and harm...

Embodiment 3

[0061] Adopt the mask material production line that can inactivate virus described in embodiment 1 to prepare the mask material that can inactivate virus, comprise the following steps:

[0062] Step 1. Mix the virus-inactivating powder with water and heat to generate high-temperature steam; the mass ratio of the virus-inactivating powder to water in step 1 is 1:4. The powder that can inactivate the virus described in step 1 includes but is not limited to the powder that can inactivate the new coronavirus, preferably a porous solid material for inactivating the virus produced by the Institute of Chemistry and Physics, Chinese Academy of Sciences, the publication number CN1552454A, a kind for Porous solid material for adsorbing and inactivating viruses and its application. The true diameter of the novel coronavirus inactivated particles is 5-10 μm. The specific gravity is close to that of water, insoluble in water, melting temperature above 1000°C, non-toxic, tasteless and harm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com