Perovskite material, preparation method thereof, light absorption layer and perovskite cell

A technology of perovskite material and light absorption layer, which is applied in photovoltaic power generation, circuits, electrical components, etc., can solve the problem that the utilization rate of photoelectric conversion efficiency materials needs to be improved, and achieve the effect of high material utilization rate and high photoelectric conversion efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

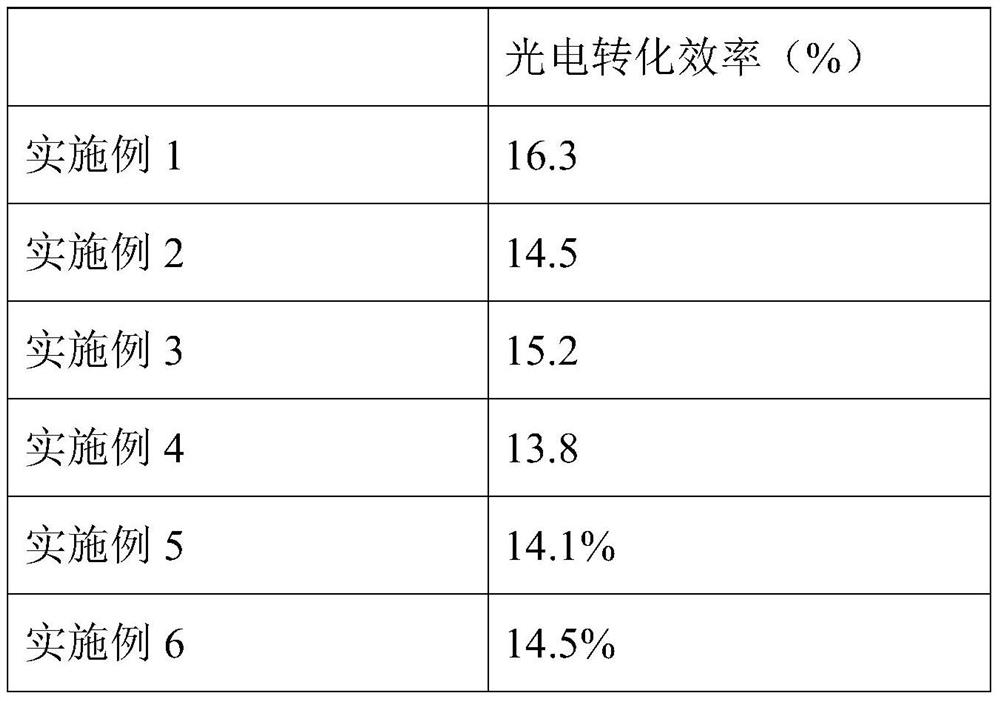

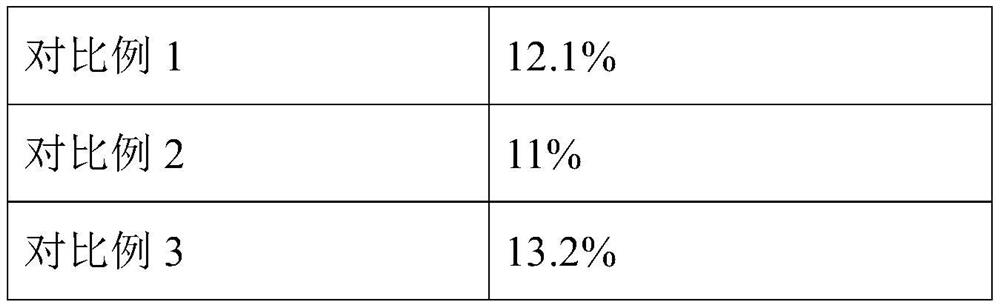

Embodiment 1

[0067] In this embodiment, the flexible perovskite battery is as follows:

[0068] 1. First, use deionized water, ethanol, acetone, isopropanol, and ultrasonic waves to clean the transparent and flexible PET substrate with the transparent conductive electrode ITO in sequence. The substrate size is 10cm×10cm.

[0069] 2. The electron transport layer PCBM was prepared on the ITO electrode by spin-coating method.

[0070] 3. Prepare the light absorbing layer FAPb(I) on the electron transport layer 0.85 Br 0.15 ) 3 .

[0071] 4. Prepare the hole transport layer PEDOT:PSS on the perovskite layer by spin-coating method.

[0072] 5. Finally, a metal gold electrode was prepared as a top electrode by a vacuum evaporation method to obtain the flexible perovskite battery.

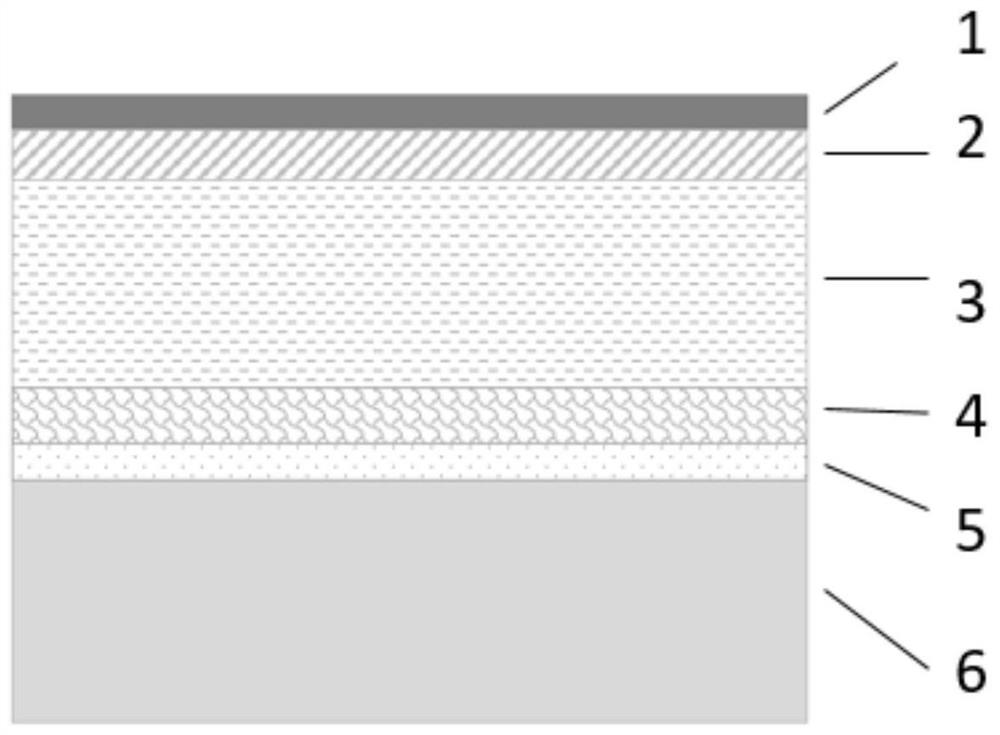

[0073] figure 1 Schematic diagram of the structure of the perovskite cell prepared for this example, as shown in the figure, the top electrode 1, the hole transport layer 2, the light absorption layer 3, the ele...

Embodiment 2

[0081] The difference between the flexible perovskite battery provided in this example and the flexible perovskite battery in Example 1 is that the composition of the light absorbing layer is MA 0.5 FA 0.5 Pb(I 0.8 Br 0.2 ) 3 , its thickness is 500nm, and its preparation steps are as follows:

[0082] (1) adopt the mixed solvent of DMF and DMSO to prepare lead iodide precursor solution, the volume ratio of DMF and DMSO is 14:0.8, the concentration of lead iodide precursor solution is 0.8mol / L, the gained lead iodide precursor The solution adopts ultrasonic spraying method to prepare lead iodide film on the substrate. The specific parameters of ultrasonic spraying are: spraying width 20 mm, spraying interval 5 mm, nozzle height 10 mm, spraying speed 200 mm / s, substrate temperature 35 °C, precursor flow rate 0.5 mL / s min, the carrier gas nitrogen pressure is 0.015MPa.

[0083] (2) A mixed solvent of DMF and DMSO is used to prepare a precursor solution containing formamidine...

Embodiment 3

[0087] The difference between the flexible perovskite battery provided in this example and the flexible perovskite battery in Example 1 is that the composition of the light absorbing layer is MAPbI 3 , its thickness is 450nm, and its preparation steps are as follows:

[0088](1) adopt the mixed solvent of DMF and DMSO to prepare lead iodide precursor solution, the volume ratio of DMF and DMSO is 14:0.5, the concentration of lead iodide precursor solution is 0.4mol / L, the gained lead iodide precursor The solution adopts ultrasonic spraying method to prepare lead iodide film on the substrate. The specific parameters of ultrasonic spraying are: spraying width 20 mm, spraying interval 5 mm, nozzle height 10 mm, spraying speed 200 mm / s, substrate temperature 35 °C, precursor flow rate 0.5 mL / s min, the carrier gas nitrogen pressure is 0.015MPa.

[0089] (2) Adopt the mixed solvent of DMF and DMSO to prepare the precursor solution containing methylamine iodide, the volume ratio of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com