Preparation method of guitar material

A guitar and sheet technology, applied in the field of guitar material preparation, can solve problems such as large differences in acoustic effects, long production cycle, complex production process, etc., and achieve the effects of excellent bending resistance, shortened growth cycle, and optimized working environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1 of the present invention: a kind of preparation method of guitar material comprises the following steps:

[0029] A. The wood fiber is made into a 280g / ㎡ sheet by roller extrusion;

[0030] B. Put the sheet into the phenolic resin mixed with flame retardant for impregnation;

[0031] C. Take out the impregnated sheet and dry it at a high temperature of 150°C for 5 minutes;

[0032] D. After stacking the dried flakes, put them on a press for high-temperature and high-pressure extrusion. The temperature is 150° C., the extrusion pressure is 1430 psi, and the extrusion time is 12 hours.

[0033] E. Cool the extruded sheet naturally, trimming, quality inspection and packaging.

[0034] The finally prepared guitar material contains 60% of wood fiber by weight, 30% of phenolic resin and 10% of flame retardant.

Embodiment 2

[0035] Embodiment 2 of the present invention: a kind of preparation method of guitar material comprises the following steps:

[0036] A. The wood fiber is made into a 280g / ㎡ sheet by roller extrusion;

[0037] B. Put the sheet into the phenolic resin mixed with flame retardant for impregnation;

[0038] C. Take out the impregnated sheet and dry it at a high temperature of 140°C for 6 minutes;

[0039] D. After stacking the dried flakes, put them on a press for high-temperature and high-pressure extrusion. The temperature is 140° C., the extrusion pressure is 1430 psi, and the extrusion time is 15 hours.

[0040] E. Cool the extruded sheet naturally, trimming, quality inspection and packaging.

[0041] The finally prepared guitar material contains 65% of wood fiber by weight, 27% of phenolic resin and 8% of flame retardant.

Embodiment 3

[0042] Embodiment 3 of the present invention: a kind of preparation method of guitar material comprises the following steps:

[0043] A. The wood fiber is made into a 280g / ㎡ sheet by roller extrusion;

[0044] B. Put the sheet into the phenolic resin mixed with flame retardant for impregnation;

[0045] C. Take out the impregnated sheet and dry it at a high temperature of 160°C for 4 minutes;

[0046] D. After stacking the dried flakes, put them on a press for high temperature and high pressure extrusion. The temperature is 160°C, the extrusion pressure is 1430psi, and the extrusion time is 10h.

[0047] E. Cool the extruded sheet naturally, trimming, quality inspection and packaging.

[0048] The finally prepared guitar material contains 55% of wood fiber by weight, 35% of phenolic resin and 10% of flame retardant.

PUM

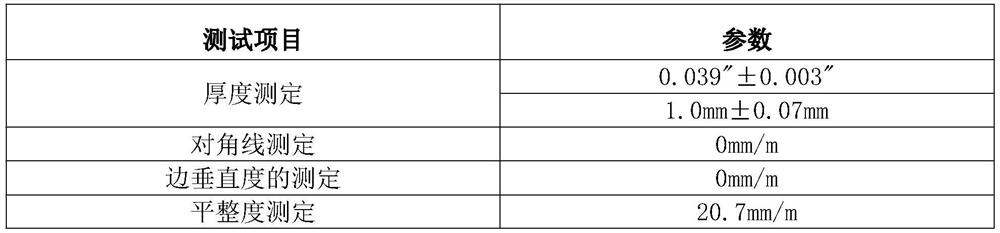

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com