Method for preparing activated carbon by taking camellia oleifera shells as raw materials through microwave chemical activation method

A technology for preparing activated carbon and Camellia oleifera husk, which is applied in chemical instruments and methods, inorganic chemistry, carbon compounds, etc., can solve the problems of environmental hazards of waste water and waste gas, large consumption of activators, and long activation time, so as to expand sources and reduce The effect of production cost and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

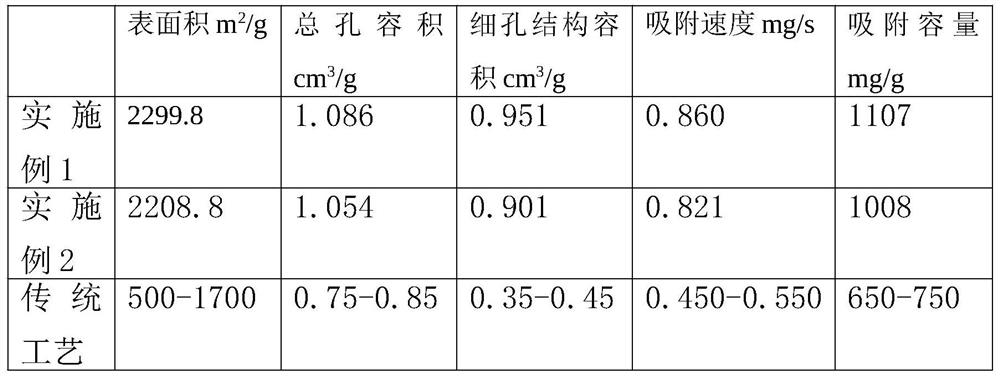

Examples

Embodiment 1

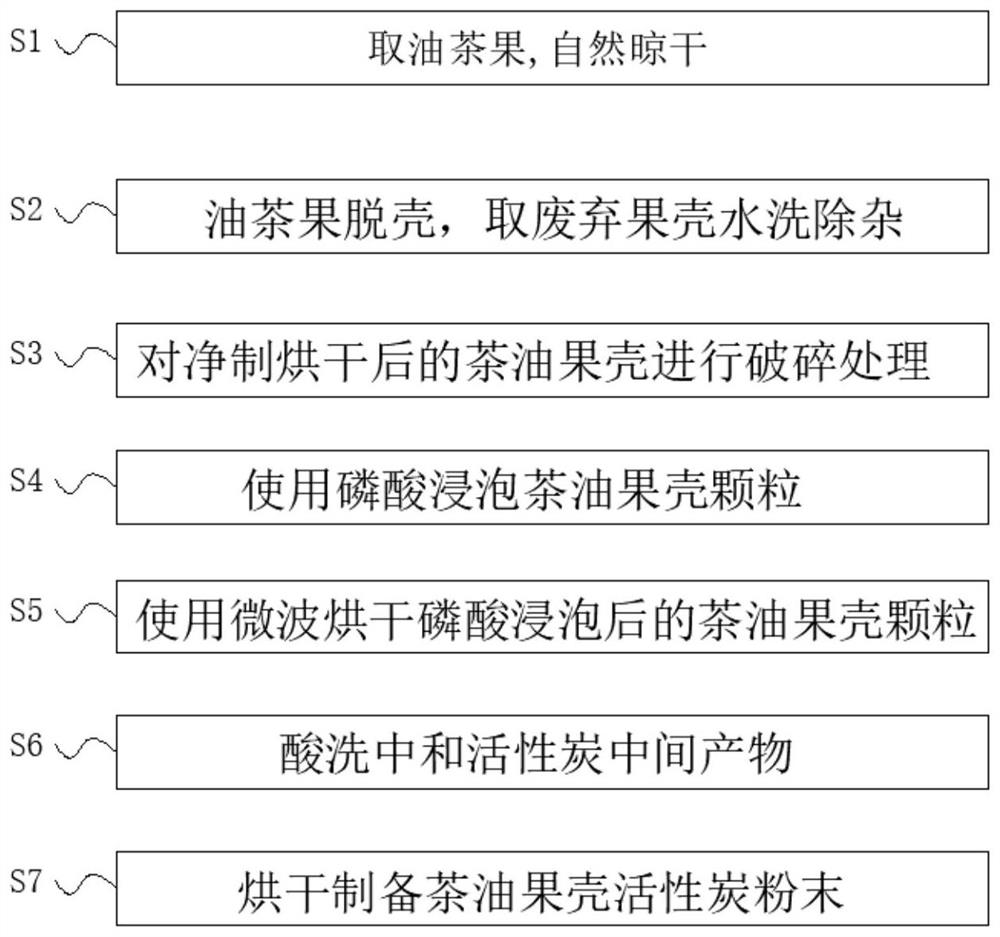

[0031] A method for preparing activated carbon by microwave chemical activation method using camellia oleifera husk as raw material, comprising the steps of:

[0032] Step 1: Take the camellia oleifera fruit and dry it naturally. After the first ten days of October, the oil content of the camellia oleifera fruit reaches the highest peak, which is the fully mature stage. Observe with the naked eye that the hair of the fruit peel will naturally fall off, and it will become smooth and bright, and crack at 10% After collection, it is placed in a ventilated place to dry naturally until the water content drops below 10%;

[0033] Step 2: Shelling the camellia oleifera fruit, washing the discarded husk to remove impurities, and drying, taking the seeds of the dried camellia oleifera fruit, collecting the exhaust gas husk, and cleaning the surface of the husk until the surface of the husk and internal sundries are completely removed, and finally placed in a drying device for drying at...

Embodiment 2

[0043] A method for preparing activated carbon by microwave chemical activation method using camellia oleifera husk as raw material, comprising the steps of:

[0044] Step 1: Take the camellia oleifera fruit and dry it naturally. After the first ten days of October, the oil content of the camellia oleifera fruit reaches the highest peak, which is the fully mature stage. Observe with the naked eye that the hair of the fruit peel will naturally fall off, and it will become smooth and bright, and crack at 10% After collection, it is placed in a ventilated place to dry naturally until the water content drops below 10%;

[0045]Step 2: Shelling the camellia oleifera fruit, washing the discarded husk to remove impurities, and drying, taking the seeds from the dried camellia oleifera fruit, collecting the exhausted husk, and cleaning the surface of the husk until the surface of the husk and internal sundries are completely removed, and finally placed in a drying device for drying at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com