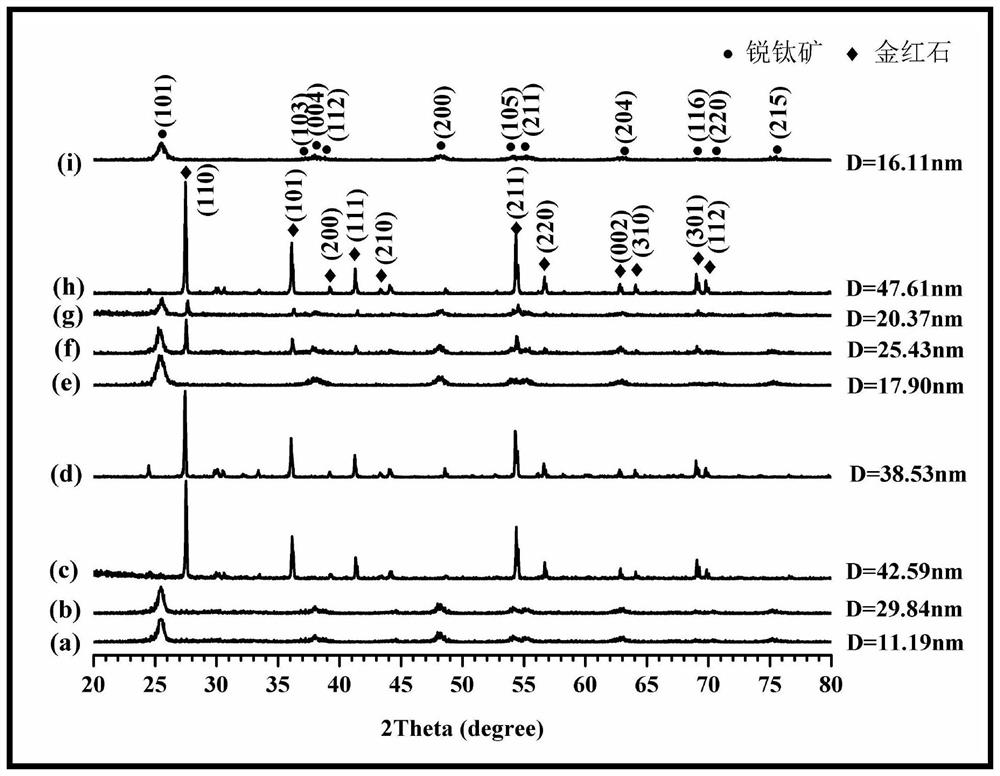

Method for preparing titanium dioxide powder with different morphologies by solid phase method

A technology of titanium dioxide and solid-phase method, which is applied in the direction of titanium dioxide, titanium oxide/hydroxide, nanotechnology, etc., can solve the problems of strict equipment material requirements, rare literature reports, high process temperature, etc., achieve green output and easy experiment The effect of simple process and process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

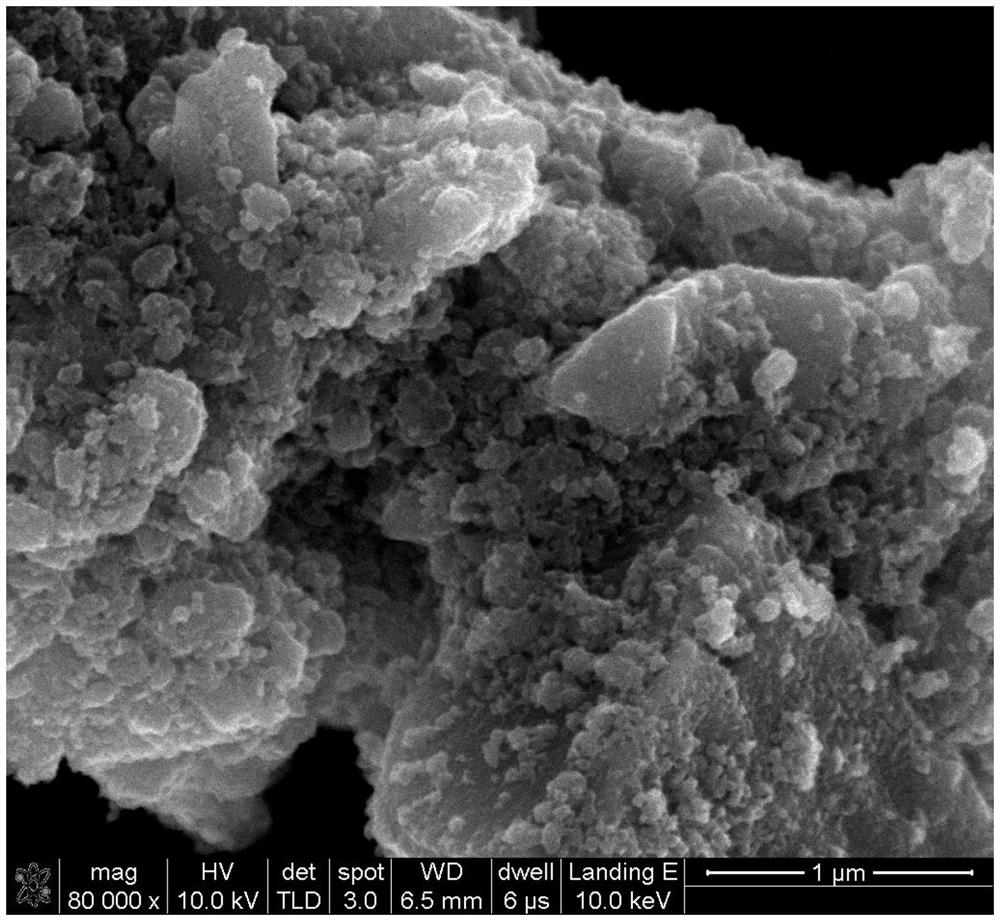

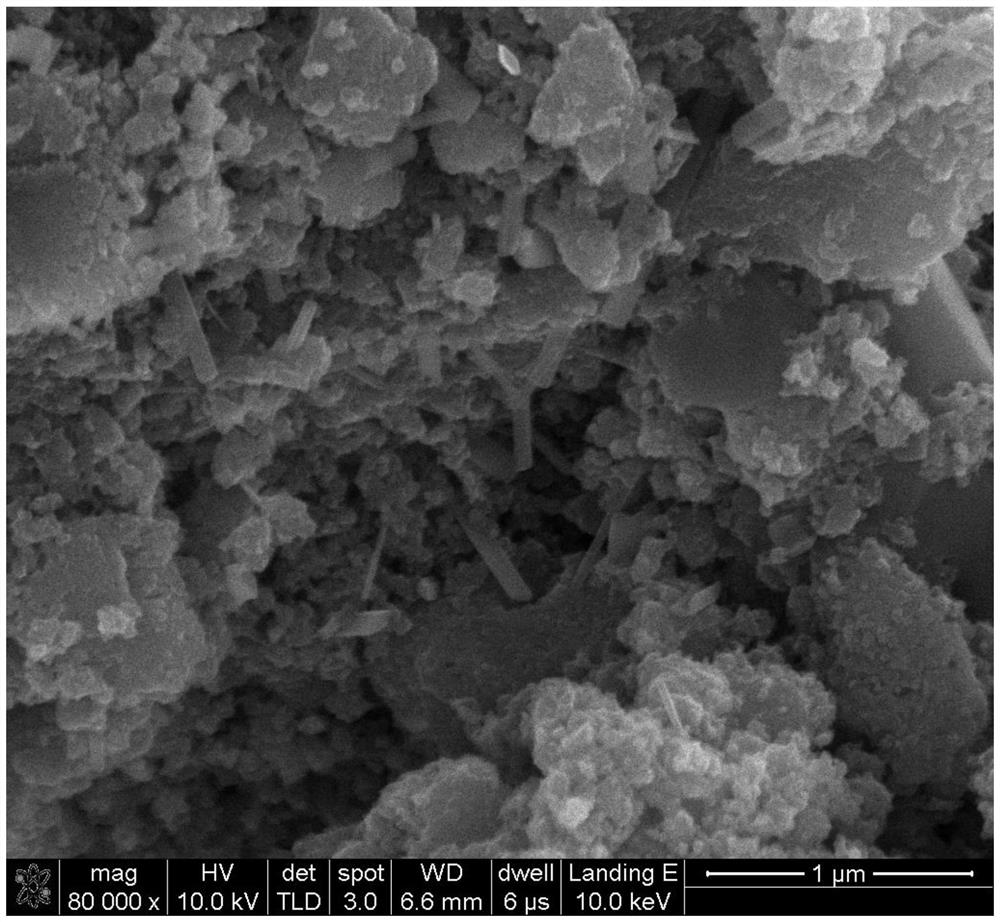

Image

Examples

Embodiment 1

[0040] S1. Weigh 8.00g (0.05mol) titanyl sulfate solid and 5.30g (0.05mol) sodium carbonate solid in a ceramic mortar;

[0041] S2, the surfactant that adds is cetyltrimethylammonium bromide (CTAB), and grinds 3min in ceramic mortar, and the consumption of surfactant accounts for the ratio of reactant total consumption and is 2%;

[0042] S3, adding 3mL of water into the solid mixture, and continue grinding for 60min;

[0043] S4. After grinding, transfer the mixture to a centrifuge tube, and centrifuge on a centrifuge. After the end, pour off the supernatant, add water, stir with a glass rod for 2min-5min, and centrifuge again. Repeat the centrifugation for 3 times to complete 3 Secondary washing process;

[0044] S5. Drying the washed solid in an oven at 110° C. for 1 hour;

[0045] S6, putting the dried powder into a muffle furnace for 1.5h and calcining at a temperature range of 500°C;

[0046] S7. Finally, put the calcined sample into a sample bag for later use.

[00...

Embodiment 2

[0049] S1. Weigh 8.00g (0.05mol) titanyl sulfate solid and 5.30g (0.05mol) sodium carbonate solid in a ceramic mortar;

[0050] S2, the tensio-active agent that adds is sodium dodecylbenzenesulfonate (SDBS), and grinds 3min in ceramic mortar, and the consumption ratio of tensio-active agent accounts for reactant total consumption is 4%;

[0051] S3, adding 3mL of water into the solid mixture, and continue grinding for 60min;

[0052] S4. After grinding, transfer the mixture to a centrifuge tube and centrifuge on a centrifuge. After the end, pour off the supernatant, add water, stir with a glass rod for 2min-5min, and centrifuge again. Repeat the centrifugation 4 times to complete 4 Secondary washing process;

[0053] S5. Drying the washed solid in an oven at 100° C. for 2 hours;

[0054] S6. Put the dried powder into a muffle furnace for calcination for 1 hour, and the calcination temperature range is 700° C.;

[0055] S7. Finally, put the calcined sample into a sample bag ...

Embodiment 3

[0058] S1. Weigh 8.00g (0.05mol) titanyl sulfate solid and 5.30g (0.05mol) sodium carbonate solid in a ceramic mortar;

[0059] S2, the surfactant that adds is the polyethylene glycol (PEG-10000) that the molecular weight of nonionic surfactant is 10000, and the consumption ratio of surfactant accounts for the total consumption of reactant is 6%;

[0060] S3, adding 3mL of water into the solid mixture, and continue grinding for 60min;

[0061] S4. After grinding, transfer the mixture to a centrifuge tube, and centrifuge on a centrifuge. After the end, pour off the supernatant, add water, stir with a glass rod for 2min-5min, and centrifuge again. Repeat the centrifugation for 3 times to complete 3 Secondary washing process;

[0062] S5. Drying the washed solid in an oven at 100° C. for 1 hour;

[0063] S6. Put the dried powder into a muffle furnace for calcination for 1 hour, and the calcination temperature range is 900° C.;

[0064] S7. Finally, put the calcined sample into...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com