Method for continuously producing monochloroacetone by micro-droplet reactor

A chloroacetone and reactor technology, which is applied in the field of continuous production of high-purity monochloroacetone in a microdroplet reactor, can solve the problems of reduced output, high system energy consumption, low purity of monochloroacetone, etc., and achieves a reduction in polychlorinated products. Generate, operate efficiently and continuously, and purify the effect easily

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

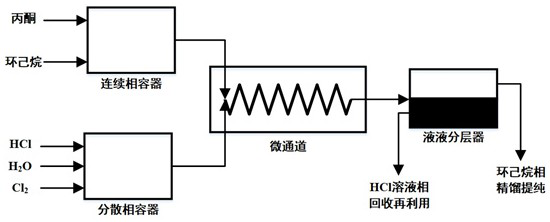

Embodiment 1

[0023] Prepared into 35wt% HCl solution under normal temperature and pressure, and passed Cl 2 Saturate to form a dispersed phase, Cl in the dispersed phase 2 The molar concentration is 0.02mol / L. The mass fractions of acetone and cyclohexane in the continuous phase were 20% and 80%, respectively. The dispersed phase and the continuous phase were injected by two syringe pumps into a microchannel made of PTFE and a diameter of 1 mm, respectively. The volume flow ratio of the two phases was 1:1, the reaction temperature was 20 °C, and the total volume flow was 2ml / min, the reaction time was 5 min, and the reaction pressure was 0.2 MPa. The liquid-liquid two-phase leaving the microchannel is layered in a liquid-liquid stratifier, and the cyclohexane phase containing monochloroacetone is put into a rectifying tower for rectification separation, and the content of the obtained monochloroacetone is as high as 99.5%.

Embodiment 2

[0025] Prepare 35% HCl solution at normal temperature and pressure, and pass Cl 2 Saturate to form a dispersed phase, Cl in the dispersed phase 2 The molar concentration is 0.02mol / L. The mass fractions of acetone and cyclohexane in the continuous phase were 20% and 80%, respectively. The dispersed phase and the continuous phase were injected into a microchannel made of PTFE and a diameter of 1 mm by two syringe pumps respectively. The volume flow ratio of the two phases was 1:1, the reaction temperature was 30 °C, and the total volume flow was 2ml / min, the reaction time was 5 min, and the reaction pressure was 0.2 MPa. The liquid-liquid two-phase leaving the microchannel is layered in a liquid-liquid stratifier, and the cyclohexane phase containing monochloroacetone is put into a rectifying tower for rectification separation, and the content of the obtained monochloroacetone is as high as 99.1%.

Embodiment 3

[0027] Prepare 35% HCl solution at normal temperature and pressure, and pass Cl 2 Saturate to form a dispersed phase, Cl in the dispersed phase 2 The molar concentration is 0.02mol / L. The mass fractions of acetone and cyclohexane in the continuous phase were 20% and 80%, respectively. The dispersed phase and the continuous phase were injected by two syringe pumps into a microchannel made of PTFE and a diameter of 1mm, respectively. The volume flow ratio of the two phases was 1:2, the reaction temperature was 30 °C, and the total volume flow was 4ml / min, the reaction time was 5 min, and the reaction pressure was 0.2 MPa. The liquid-liquid two-phase leaving the microchannel is layered in a liquid-liquid stratifier, and the cyclohexane phase containing monochloroacetone is put into a rectifying tower for rectification separation, and the content of the obtained monochloroacetone is as high as 99.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com