Corrosion-resistant POK/glass fiber masterbatch applied to automobile parts and preparation method of corrosion-resistant POK/glass fiber masterbatch

A technology of auto parts and glass fiber masterbatch, which is applied in the field of modification of polymer composite materials, can solve the problems of overall material performance degradation, corrosion resistance degradation, anti-alcoholysis agent or alcoholysis-resistant agent decomposition, etc., to achieve improvement Hydroalcolysis resistance, good effect on sample surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

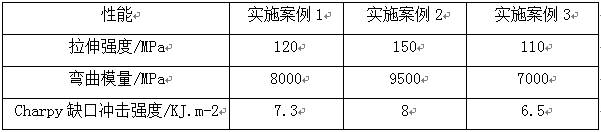

Embodiment 1

[0036] A corrosion-resistant POK / glass fiber masterbatch applied to auto parts, comprising the following components and parts by weight:

[0037] POK resin: 27.7%; glass fiber GF: 60%; glass microspheres: 7%; high-density polyethylene grafted maleic anhydride: 4%; a mixture of amines and phosphites with a mass ratio of 1:1: 0.2 %; calcium stearate: 0.2%; hyperbranched polyester: 0.6%; release agent: 0.3%.

[0038] Its preparation method comprises the following steps:

[0039] (1) POK resin, glass beads and various additives are mixed in the mixer at a high speed (3000 rpm) and then added from the main feeding port;

[0040] (2) The glass fiber is fed into double (or single) screw extruder by means of double-side feeding for melt extrusion; the extrusion temperature is 240°C, and the screw speed is 400rpm;

[0041] (3) The composition can be obtained by granulating with a granulator; the particle length is 9mm.

Embodiment 2

[0043] A corrosion-resistant POK / glass fiber masterbatch applied to auto parts, comprising the following components and parts by weight:

[0044] POK resin: 13%; glass fiber GF: 70%; glass microspheres: 10%; high-density polyethylene grafted maleic anhydride: 5%; a mixture of amines and phosphites with a mass ratio of 1:1: 0.3 %; zinc stearate: 0.3%; hyperbranched polyester: 0.9%; lubricant: 0.5%.

[0045] Its preparation method is basically the same as Example 1.

Embodiment 3

[0047] A corrosion-resistant POK / glass fiber masterbatch applied to auto parts, comprising the following components and parts by weight:

[0048] POK resin: 53.3%; glass fiber GF: 40%; glass microspheres: 3.1%; high-density polyethylene grafted maleic anhydride: 3%; a mixture of amines and phosphites with a mass ratio of 1:1: 0.1 %; calcium ricinoleate: 0.1%; hyperbranched polyester: 0.3%; flow enhancer: 0.1%.

[0049] Its preparation method is basically the same as Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com