MoS2 thin film containing 1T phase and preparation process of MoS2 thin film

A thin film preparation, mos2 technology, applied in metal material coating process, ion implantation plating, coating, etc., can solve the problems that can not meet the industrial production standards, poor bonding force of film substrate, difficult to achieve mass production, etc., to achieve Easy mass production, small temperature change, good binding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The MoS containing 1T phase in this example 2 The preparation method of the film comprises the following steps.

[0030] (1) Use alcohol to ultrasonically clean the surface of the carbon fiber cloth, and dry it with a hair dryer;

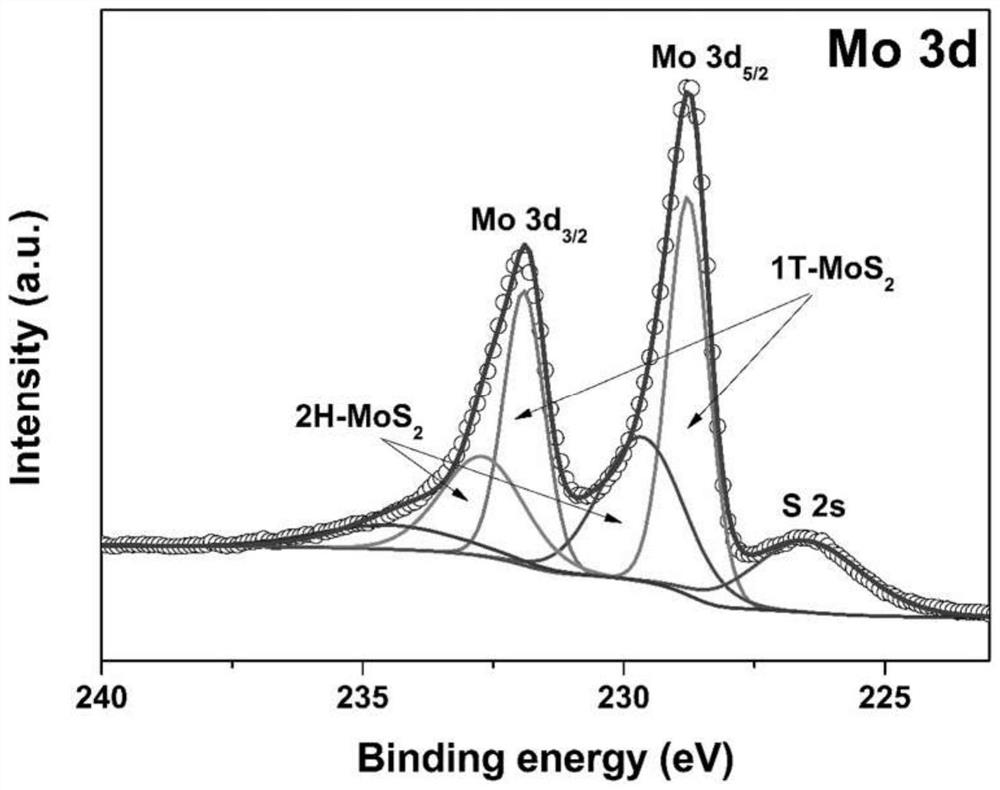

[0031] (2) Using Ar as the working gas, using MoS with a purity >99.9% 2 Co-sputtering of target and Cu target to deposit MoS with 1T phase 2 film. The sputtering reaction parameters are: the working pressure is 0.2Pa, the sample revolution speed is 0.5r / min, the temperature is 30°C, the Ar flow rate is 20sccm, the MoS 2 Adopt radio frequency power supply, power is 300W, Cu target adopts DC power supply, power is 50W.

[0032] The preparation method of this example obtains MoS containing 1T phase 2 The preparation method of the film: the surface film deposited on the carbon fiber cloth substrate by magnetron sputtering, the surface film is made of Cu-doped MoS 2 composition:

Embodiment 2

[0034] The MoS containing 1T phase in this example 2 The preparation method of film is basically the same as Example 1, the difference is only in:

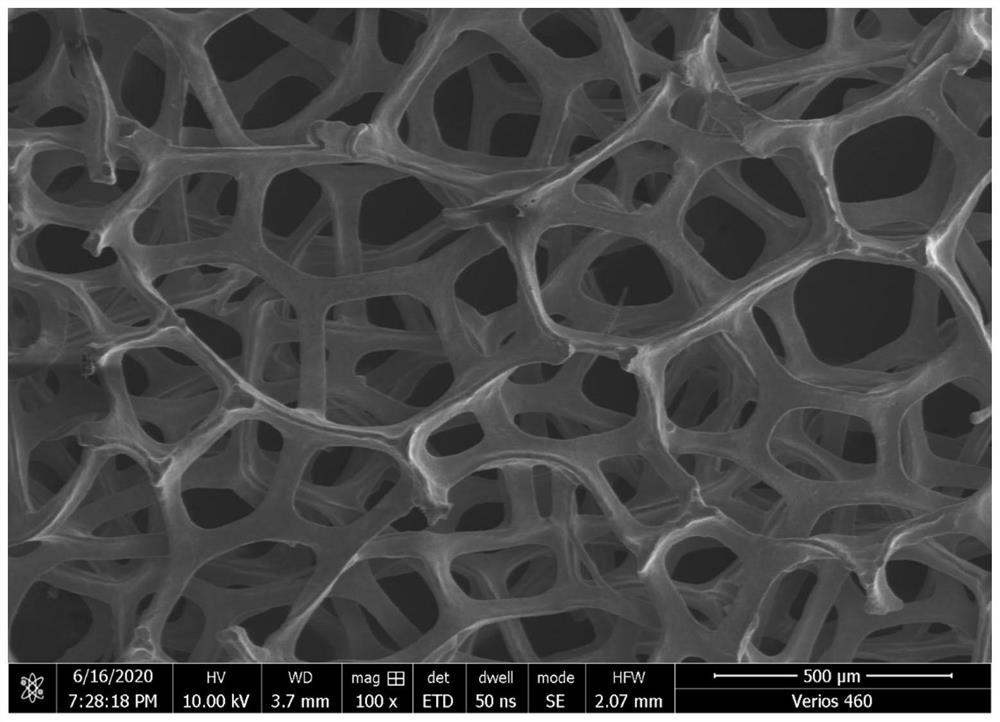

[0035] The substrate is nickel foam, MoS 2 A radio frequency power supply is used with a power of 50W, and the metal target is an Al target with a power of 5W.

[0036] The preparation method of this example obtains MoS containing 1T phase 2 The preparation method of the film: the surface film deposited on the foamed nickel substrate by magnetron sputtering, the surface film is made of Al-doped MoS 2 composition:

Embodiment 3

[0038] The MoS containing 1T phase in this example 2 The preparation method of film is basically the same as Example 1, the difference is only in:

[0039] The substrate is made of candle ash, the metal target is made of Ag, and the working pressure is 1Pa.

[0040] The preparation method of this example obtains MoS containing 1T phase 2 The preparation method of the film: the surface film deposited on the candle ash substrate by magnetron sputtering, the surface film is made of Ag-doped MoS 2 composition:

PUM

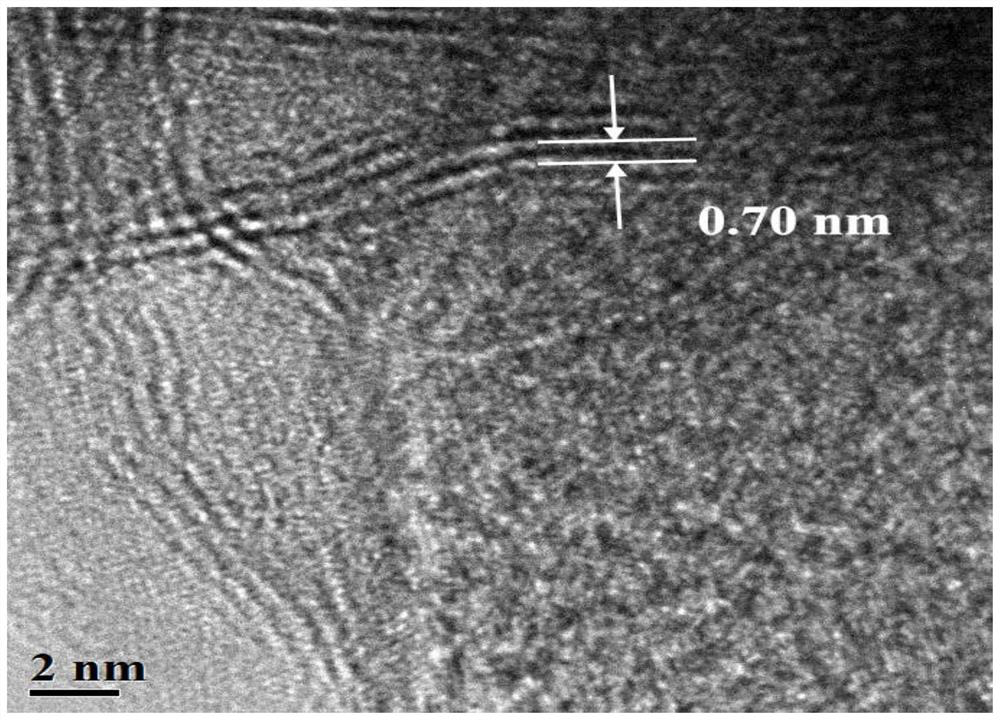

| Property | Measurement | Unit |

|---|---|---|

| lattice spacing | aaaaa | aaaaa |

| face spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com