Method for inhibiting development of water guide fracture zone of pre-mining grouting construction structure key layer

A water-conducting fracture zone and key layer technology, applied in ground mining, mining equipment, underground mining, etc., can solve the problems of reducing the development height of the water-conducting fracture zone, slurry loss, and large grouting volume, so as to protect the upper aquifer , thickness and strength increase, and the effect of increasing the limit span

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

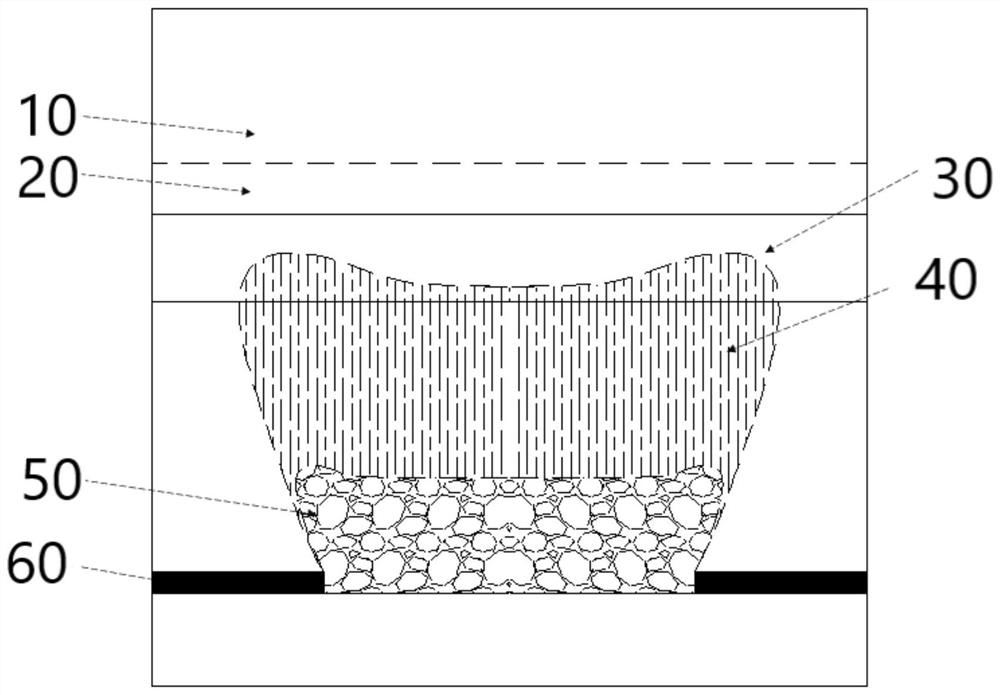

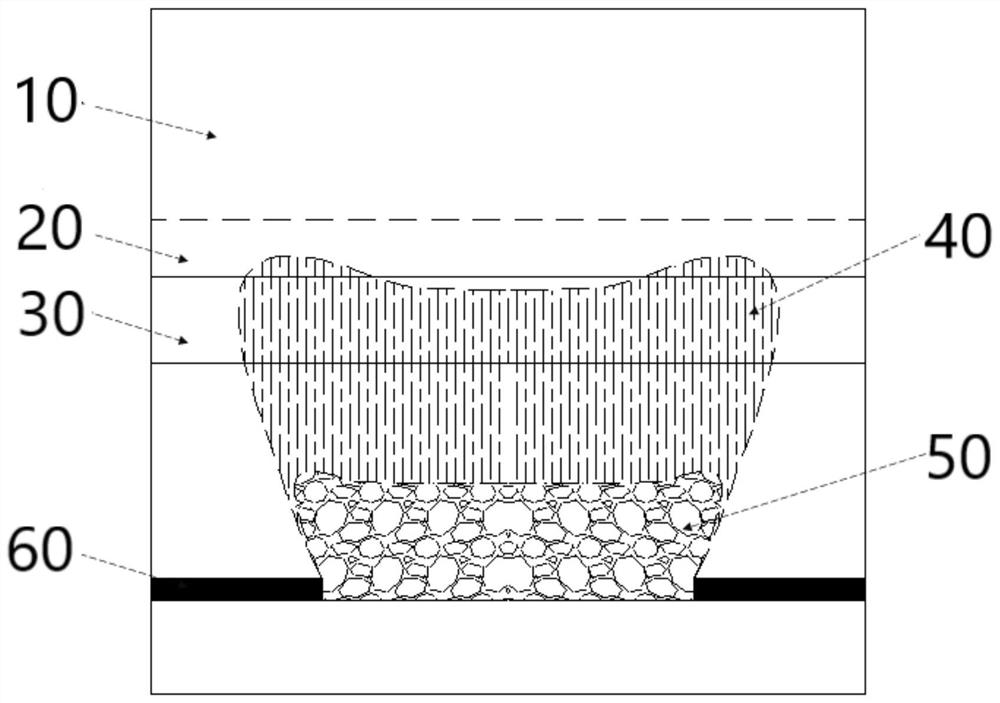

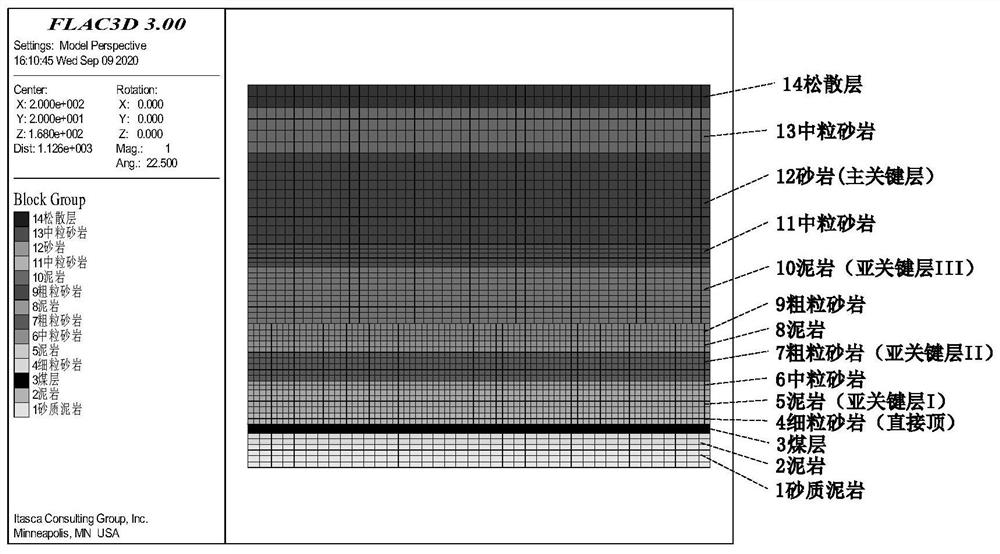

[0049] The method for inhibiting the development of the water-conducting fracture zone by pre-mining grouting to construct the key layer of the structure of the present invention analyzes and identifies the occurrence characteristics of the key layer of the primary structure of the overlying rock, predicts the development height of the water-conducting fracture zone, determines the construction level of the key layer of the artificial structure and Thickness, selection of grouting material, calibration of grouting material water-cement ratio, grouting construction of key layers of the structure, etc. Using ground horizontal holes to carry out advanced grouting to construct the structural key layer, by changing the existing characteristics such as the thickness and strength of the original overlying rock structural key layer, transforming the original load layer into the structural key layer, which can increase the limit span of the structural key layer, Inhibit the vertical dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com