Glow plasma generating device for surface modification of polymer material

A polymer material and surface modification technology, applied in the direction of plasma, electrical components, etc., can solve the problems of reducing the energy of active particles, loss of energy, action strength and reduction of modification effect, so as to inhibit the development degree, increase energy, The effect of suppressing the occurrence of filamentary discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

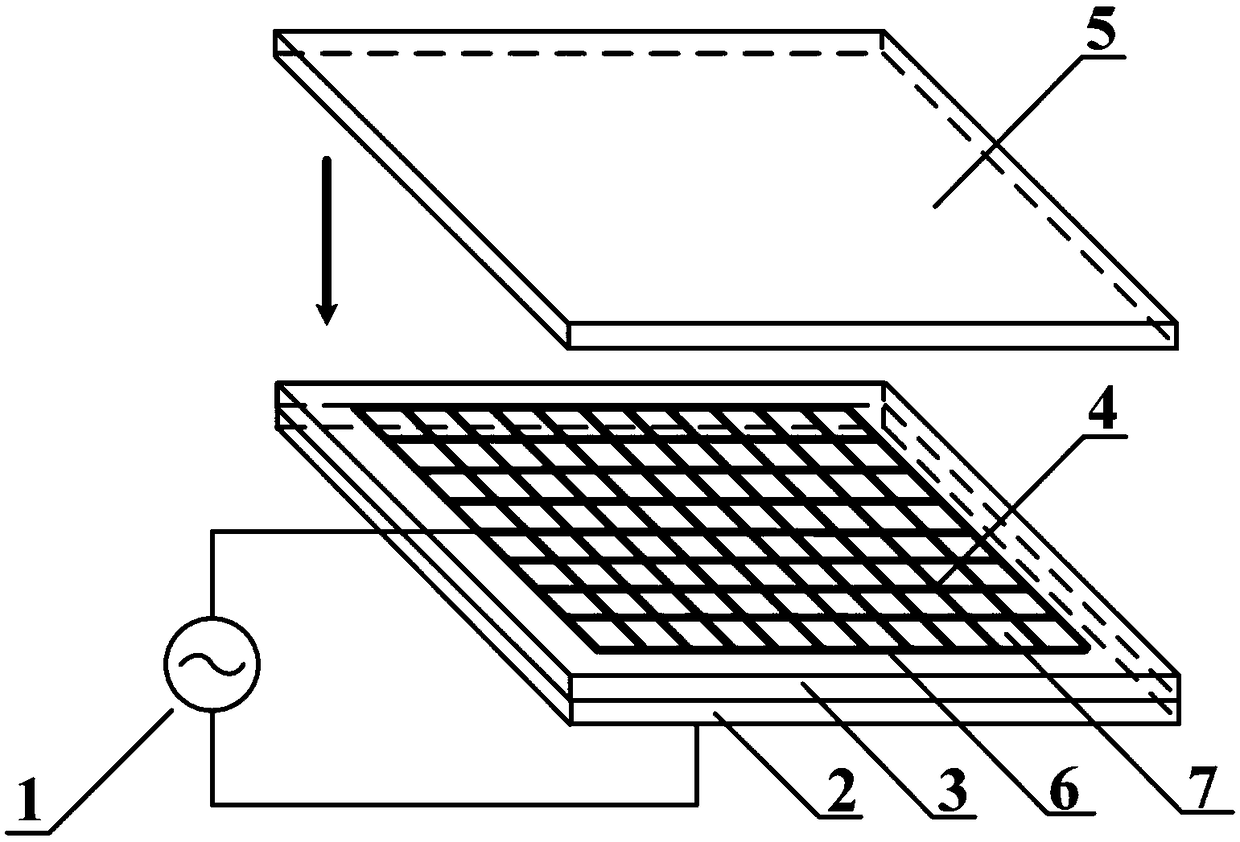

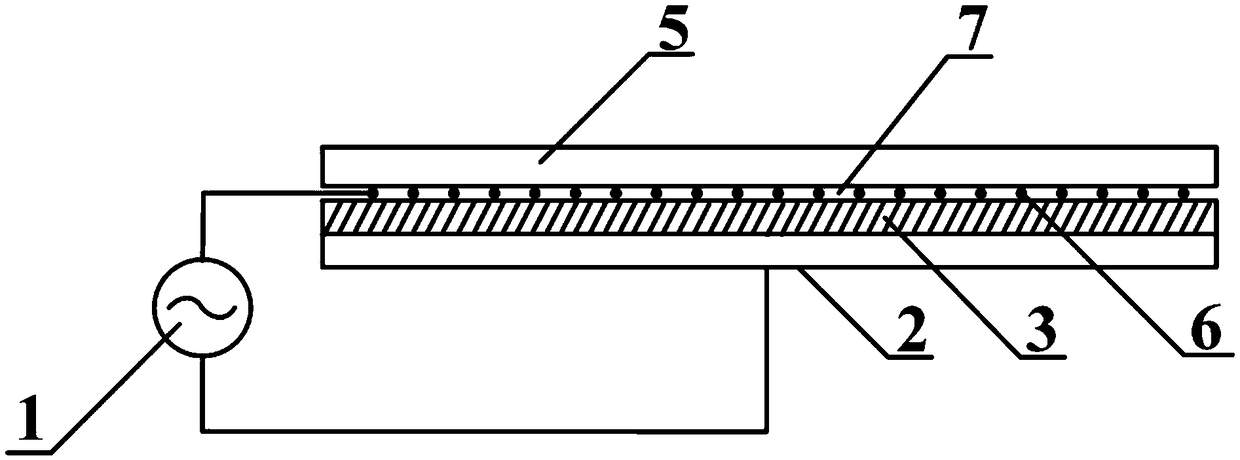

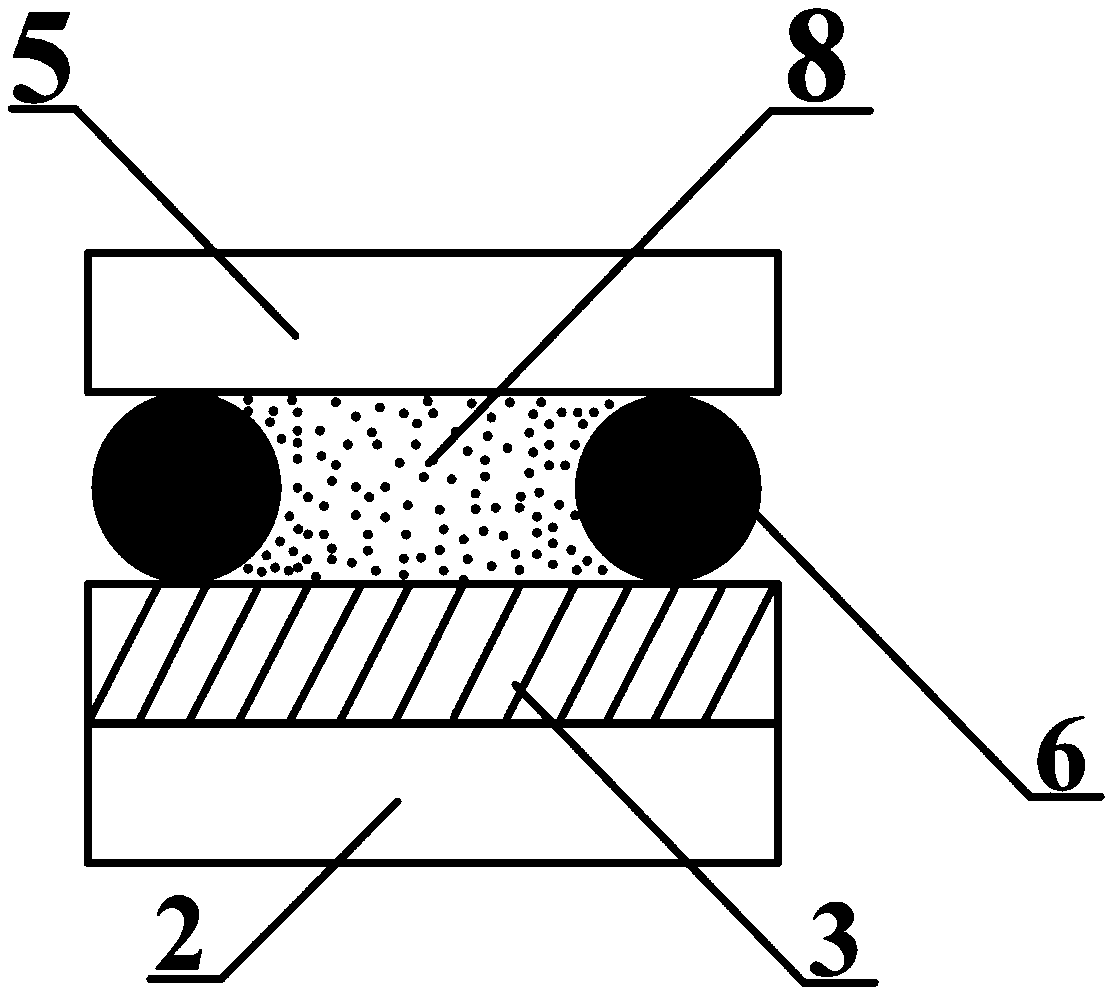

[0033] figure 1 It is a schematic structural diagram of a glow plasma generation device for surface modification of polymer materials provided by Embodiment 1 of the present invention; Figure 2a yes figure 1 A cross-sectional view of the device shown; Figure 2b yes figure 1 A partial enlarged view of the device shown. Such as figure 1 , Figure 2a and Figure 2b As shown, a glow plasma generating device for surface modification of polymer materials according to the present invention includes a high-frequency high-voltage power supply 1 , a high-voltage electrode 2 , an insulating medium 3 and a metal mesh electrode 4 . In this embodiment, the high voltage electrode 2 is a flat metal electrode 2 .

[0034] The high-voltage electrode 2 is connected to the high-voltage end of the high-voltage high-frequency power supply 1 through a lead wire, the metal mesh electrode 4 is connected to the ground end through a lead wire, and the insulating medium 3 is arranged between the...

Embodiment 2

[0040] image 3 It is a schematic structural diagram of another glow plasma generating device for surface modification of polymer materials provided by an embodiment of the present invention. Such as image 3 As shown, in the device provided in this embodiment, the metal plate electrode 2 described in Embodiment 1 is replaced by a metal roller shaft electrode 9, and a pair of driven roller shafts 10 are added to form a modified set of metal roller shaft electrodes 9. device. Spread the insulating medium 3 and the metal mesh electrode 4 along the surface of the metal roller shaft electrode 9, between the metal roller shaft electrode 9 and the insulating medium 3, between the insulating medium 3 and the metal mesh electrode 4, between the metal mesh electrode 4 and the modified The materials 5 are kept in sealing contact with each other.

[0041] In this embodiment, the metal roller electrode 9 uses copper as the electrode material to ensure its mechanical strength and good e...

Embodiment 3

[0044] Figure 4 It is a schematic structural diagram of another glow plasma generating device for surface modification of polymer materials provided by an embodiment of the present invention. Such as Figure 4 As shown, in the device provided in this embodiment, a pair of metal roller shaft electrodes 9 is set, and a pair of driven roller shafts and a pair of metal roller shaft electrodes constitute a group of modification devices, which can realize double modification of modified materials. face treatment. Spread the insulating medium 3 and the metal mesh electrode 4 along the surface of the metal roller shaft electrode 9, between the metal roller shaft electrode 9 and the insulating medium 3, between the insulating medium 3 and the metal mesh electrode 4, between the metal mesh electrode 4 and the modified The materials 5 are kept in sealing contact with each other. The rest of the structure of this embodiment is the same as that of the second embodiment.

[0045] Durin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com