Deep ultraviolet LED with stepped electron blocking layer structure and preparation method

An electronic blocking layer and stepped technology, which is applied in the direction of circuits, electrical components, semiconductor devices, etc., can solve the problems of low efficiency of deep ultraviolet LEDs, alleviate the electron overflow effect, increase the equivalent barrier height, and improve luminous efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

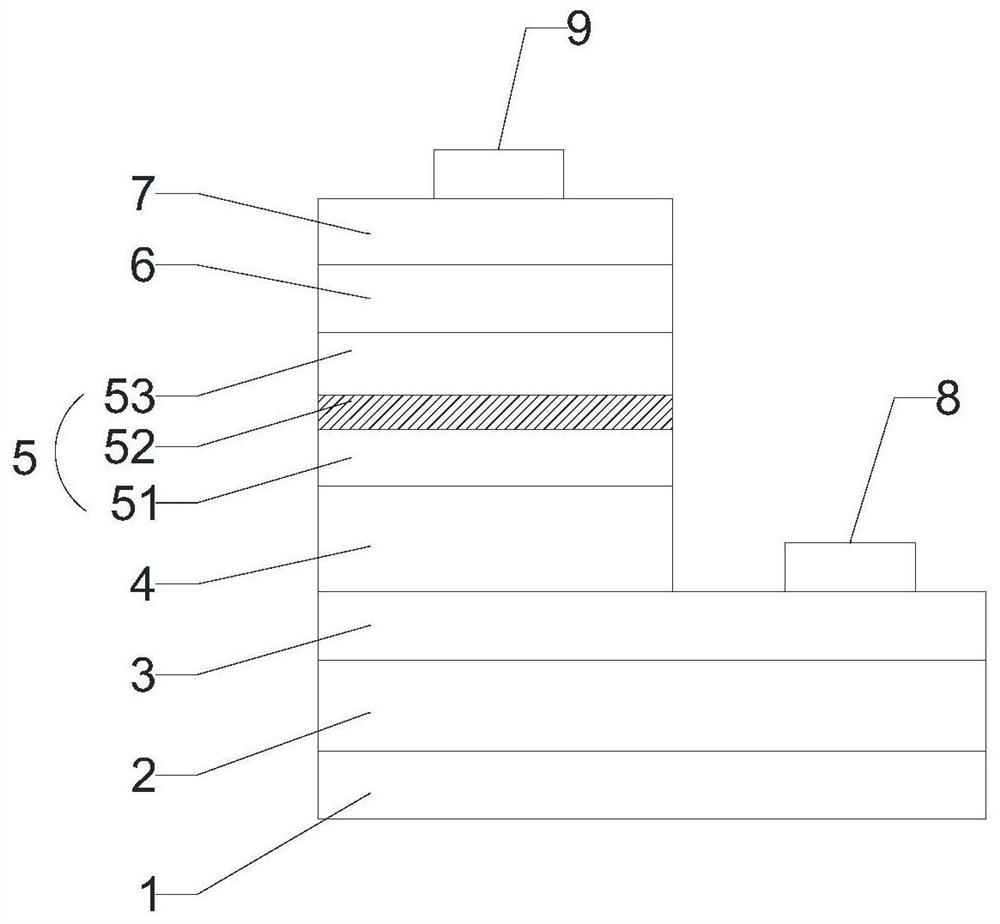

[0024] For the second solution proposed by the present invention, the steps of the method for preparing a deep ultraviolet LED with a stepped electron blocking layer structure include:

[0025] (1) Growth of AlN intrinsic layer. In this step, the low-temperature buffer layer in the AlN intrinsic layer is grown on the sapphire substrate under the condition of 400-800°C, with a thickness of 10-50nm; An intrinsic layer of AlN is grown on the layer, and the total thickness of the intrinsic layer of AlN is 500-4000nm.

[0026] (2) An n-type AlGaN electron injection layer is grown. In this step, the temperature is lowered to 800-1200°C, and an n-type AlGaN electron injection layer is grown on the AlN intrinsic layer, wherein the Al composition percentage is 20-90%, and the thickness is 500-4000nm.

[0027] (3) Growing the quantum well active layer. In this step, the temperature is lowered to 700°C to 1100°C, and a quantum well active layer is grown on the n-type AlGaN electron in...

Embodiment 1

[0034] In this example, the steps of preparing a deep ultraviolet LED with a stepped electron blocking layer structure are as follows:

[0035] (1) At 800°C, grow a low-temperature buffer layer in the AlN intrinsic layer on a sapphire substrate with a thickness of 10nm; raise the temperature to 1200°C, and grow an AlN intrinsic layer on the low-temperature buffer layer in the AlN intrinsic layer , the total thickness of the AlN intrinsic layer is 500 nm.

[0036] (2) Lower the temperature to 800°C, and grow an n-type AlGaN electron injection layer on the AlN intrinsic layer. The n-type AlGaN electron injection layer is specifically n-type Al 0.6 Ga 0.4 N, the thickness is 500-4000nm.

[0037] (3) Lower the temperature to 700°C, and grow a quantum well active layer on the n-type AlGaN electron injection layer. The quantum well active layer includes an AlGaN barrier layer and an AlGaN potential well layer. Specifically, the AlGaN barrier layer is Al 0.5 Ga 0.5 N, AlGaN poten...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com