Modified three-dimensional framework material with lithium-philic copper-nickel bimetallic layer and its preparation method and application

A bimetallic layer, three-dimensional skeleton technology, applied in the field of nanomaterials and electrochemistry, can solve the problems of complex preparation process raw materials, reduce the possibility and other problems, and achieve the effects of stable circulation, mild conditions and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The present invention provides a method of preparing the above-mentioned translucent copper nickel bipolar layer modified three-dimensional skeleton material, including the following steps:

[0026] (1) Mix the copper sulfate, nickel sulfate, boric acid with deionized water to obtain an electroplating solution;

[0027] (2) The obtained plating solution is used as the electrolyte, and the foam material is used as the working electrode, and the electroplating process is performed by the three electrode and the electrochemical workstation to obtain a modified three-dimensional bilateral material having a lithium copper nickel bis metal layer.

[0028] The present invention mixes copper sulfate, nickel sulfate, boric acid with deionized water to obtain an electroplating solution. The present invention can be used for foam nickel known to those skilled in the art. In the present invention, the molar concentration of the copper sulfate, nickel sulfate, and aqueous acid solution ...

Embodiment 1

[0040] Preparation method with lithium lithium copper nickel bimetal layer modified three-dimensional skeleton material, including the following steps:

[0041] 1) 2.5 mmol of copper sulfate, 50 mmol of nickel sulfate, 25 mmol of boric acid was dissolved in 50 ml of deionized water at 30 ° C for 20 minutes to dissolve the plating solution;

[0042] 2) At step 1) The plated liquid obtained as the electrolyte, using the three electrode and the electrochemical workstation, the electroplating voltage is set to 0.75V, and the plating time is set to 400 s;

[0043] 3) The product obtained in step 2) was taken out, and twice was washed twice with deionized water and anhydrous ethanol, and the three-dimensional bilayer material having a lithium copper nickel bilayer layer was obtained.

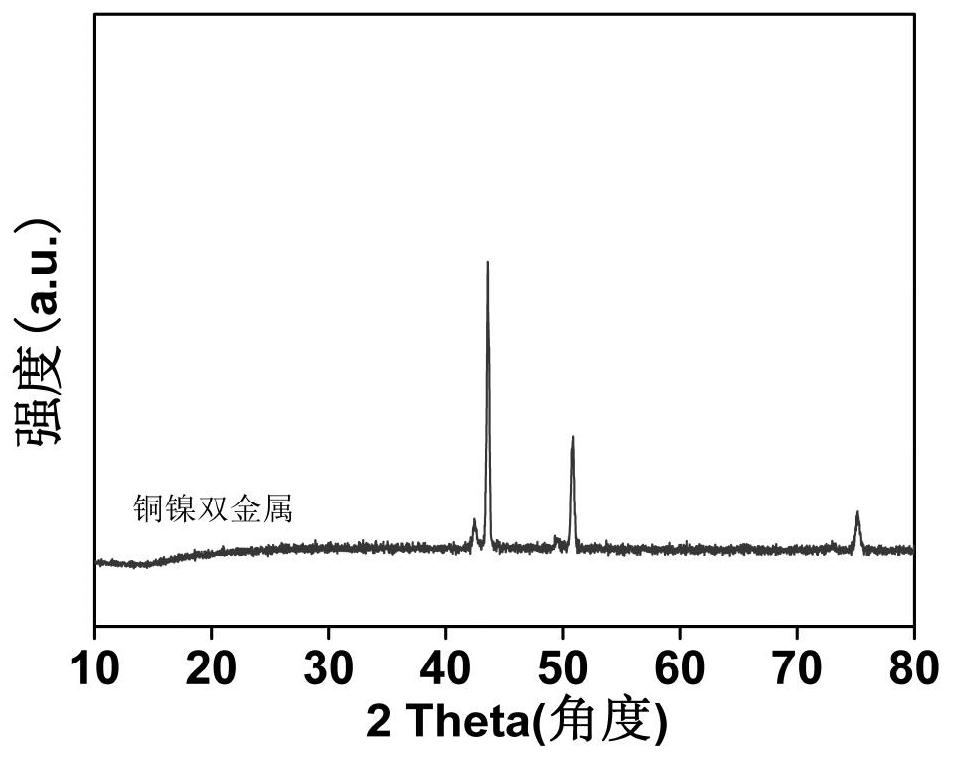

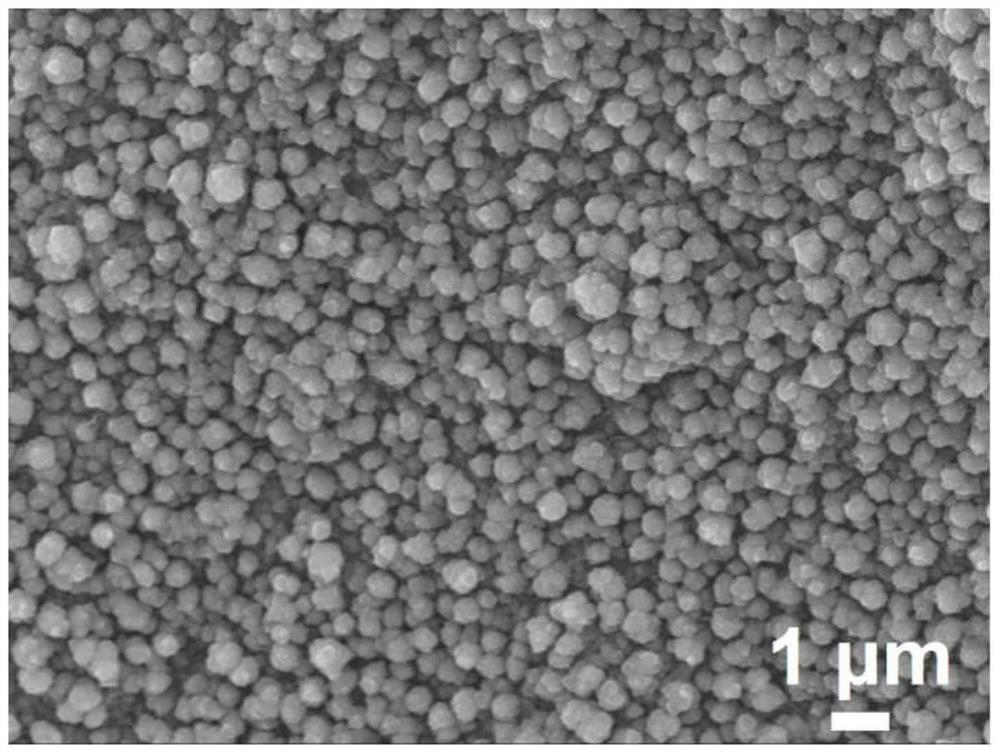

[0044] X-ray diffraction (XRD) analysis of transal lithium copper nickel bimetal layer modified three-dimensional skeleton material, the resulting X-ray diffraction spectrum figure 1 Indicated. Depend on ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com