Medicine-loaded nano robot and preparation method therefor

A drug-loaded nano-robot technology, applied in the nano-field, can solve the problems of initial drug burst release and low drug encapsulation rate, and achieve the effects of reducing burst release wind, good magnetic properties, and improving drug encapsulation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The invention provides a preparation method of a drug-loaded nanorobot, comprising the following steps:

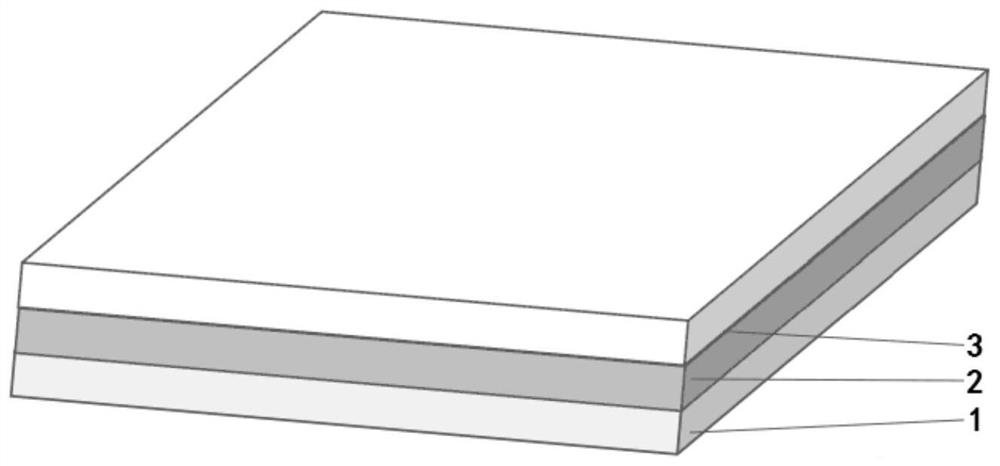

[0032] a) Provided that the surface is provided with SiO 2 The base substrate of the film layer;

[0033] b) on the SiO 2 coating the gelatin solution on the film layer, and curing the gelatin solution to form the first gelatin film layer;

[0034] c) coating a magnetic material on the first gelatin film layer to form a magnetic film layer;

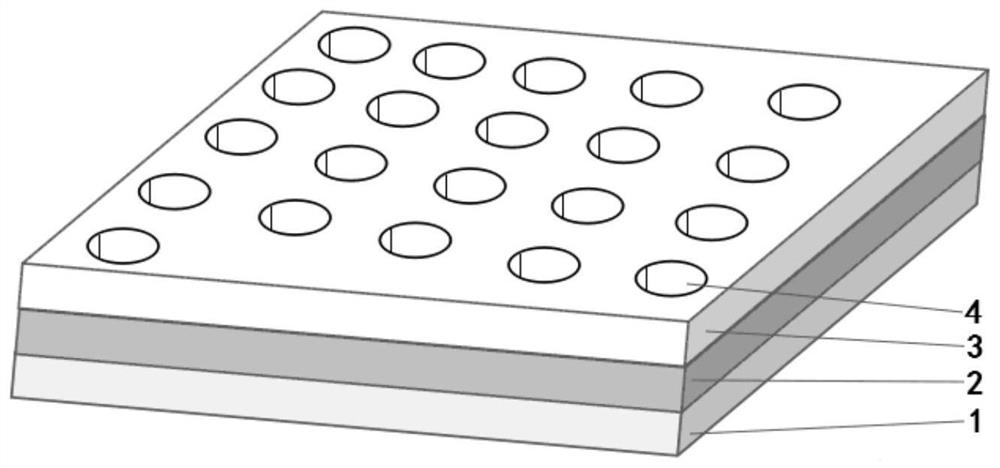

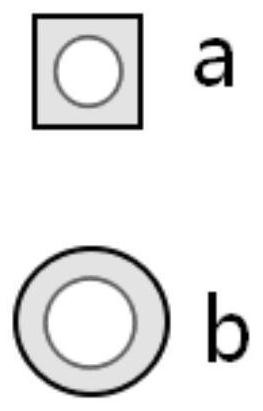

[0035] d) performing photoetching on the magnetic film layer to form photoetching grooves;

[0036] e) loading the drug into the photoresist groove, and then using a gelatin solution to seal the notch of the photoresist groove, and the gelatin solution is solidified to form a second gelatin film layer;

[0037] f) Under heating conditions, the fully encapsulated multilayer composite along its SiO 2 The film layer is separated from the bonding surface of the first gelatin film layer to obtain a drug-loaded nanorobot.

[00...

Embodiment 1

[0064] Prepare drug-loaded nanorobots according to the following specific process route: cleaning → magnetron sputtering SiO 2 Film layer→coating the first gelatin film layer→sputtering magnetic film layer→laser lithography→drug loading→encapsulation (coating the second gelatin film layer)→cutting→peeling→drying and sterilizing.

[0065] 1) Cleaning:

[0066] Wipe the glass substrate substrate with a size of 200mm×200mm×0.5mm with alcohol, then put it into an ultrasonic cleaner (ultrasonic power 150W), super-clean with deionized water, super-clean with alcohol, and finally put the substrate in alcohol vapor for cleaning Drying, when the substrate is taken out from the steam, because the condensed steam evaporates from the surface, the substrate substrate can be dried quickly.

[0067] 2) Magnetron sputtering SiO 2 Film layer:

[0068] Coating a layer of SiO on the substrate by vacuum magnetron sputtering 2 The substrate protective layer, vacuum magnetron sputtering coating...

Embodiment 2

[0114] Prepare drug-loaded nanorobots according to the following specific process route: cleaning → magnetron sputtering SiO 2 Film layer→coating the first gelatin film layer→sputtering magnetic film layer→laser lithography→drug loading→encapsulation (coating the second gelatin film layer)→cutting→peeling→drying and sterilizing.

[0115] 1) Cleaning:

[0116] Wipe the glass substrate substrate with a size of 200mm×200mm×0.5mm with alcohol, then put it into an ultrasonic cleaner (ultrasonic power 150W), super-clean with deionized water, super-clean with alcohol, and finally put the substrate in alcohol vapor for cleaning Drying, when the substrate is taken out from the steam, because the condensed steam evaporates from the surface, the substrate substrate can be dried quickly.

[0117] 2) Magnetron sputtering SiO 2 Film layer:

[0118] Coating a layer of SiO on the substrate by vacuum magnetron sputtering 2 The substrate protective layer, vacuum magnetron sputtering coating...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com