Biochar prepared by co-pyrolysis of excess sludge and hazelnut shells and photocatalytic modification method of biochar

A technology for excess sludge and biochar, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc. Solve the problems of low sunlight utilization rate and achieve the effect of no secondary pollution, good adsorption performance and high reuse rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

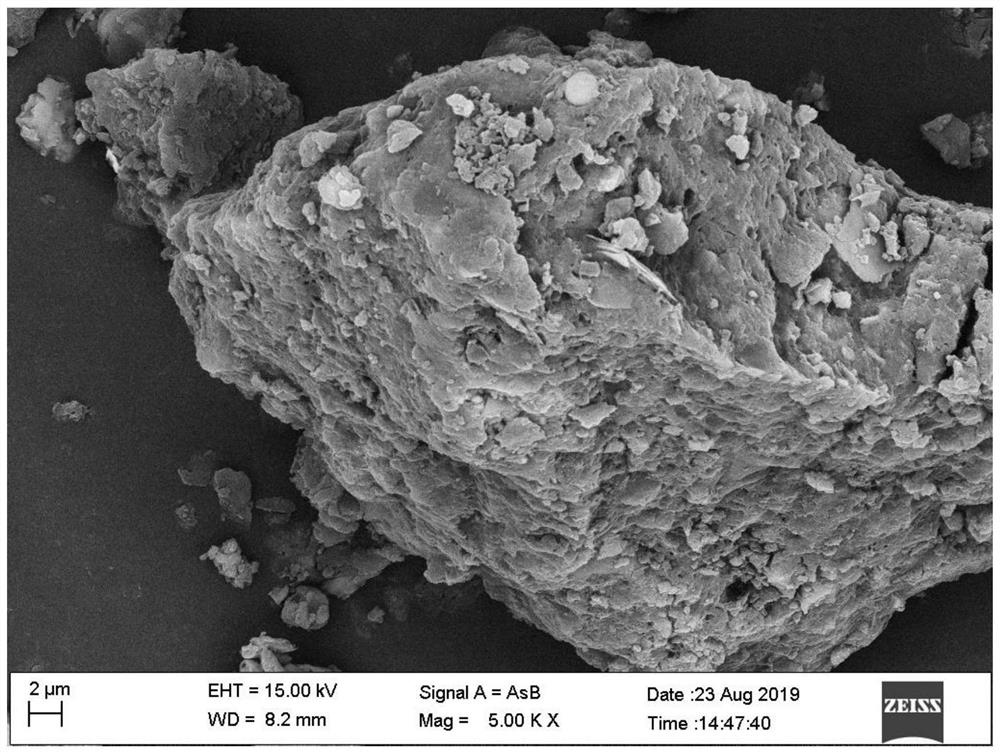

[0062] Separately dry the remaining sludge and hazelnut shells at 100-105°C for 24 hours and then break them into solid particles below 1 mm: mix the remaining sludge and hazelnut shells according to the mass percentage of 30% of the hazelnut shells in the mixture, and pass through 4mol / L The potassium carbonate solution was soaked and activated at room temperature with a liquid-solid ratio of 2:1 for 24 hours, and then dried at 100-105°C; the dried mixed particles were vacuum-heated to 800°C at a rate of 10°C / min and kept for 1 hour; The pyrolyzed product is washed successively with dilute hydrochloric acid and deionized water, and dried at 100-105°C to obtain biochar with a yield of 52.5%. In terms of adsorption performance: the specific surface area is 768.33m 2 / g, iodine adsorption value: 673.26mg / g. figure 2 The appearance diagram of the biochar prepared in Example 1 of the present invention is provided. The solid particles are uniform and fine, shiny, good in appeara...

Embodiment 2-1

[0064] Separately dry the remaining sludge and hazelnut shells at 100-105°C for 24 hours and then break them into solid particles below 1 mm: mix the remaining sludge and hazelnut shells according to the mass percentage of 30% of the hazelnut shells in the mixture, and pass through 4mol / L The potassium carbonate solution was soaked and activated at room temperature with a liquid-solid ratio of 2:1 for 24 hours, and then dried at 100-105°C; the dried mixed particles were vacuum-heated to 800°C at a rate of 10°C / min and kept for 1 hour; The pyrolyzed product is washed successively with dilute hydrochloric acid and deionized water, and dried at 100-105°C to obtain biochar with a yield of 52.5%. Dissolve 4mmol of zinc chloride in 60ml of deionized water, add 20mmol of sodium hydroxide under constant stirring, after completely dissolving, mix according to the mass ratio of biochar and catalyst raw materials at 1:1, and prepare the solution Place in a glass bottle and prepare at a c...

Embodiment 2-2

[0066] Same as Example 2-1, the difference is that the mass ratio of biochar to catalyst raw material is 1:3, and the nano-ZnO composite biochar material is obtained. In terms of adsorption performance: the specific surface area is 613.13m 2 / g, iodine adsorption value: 532.52mg / g, photocatalytic methyl orange degradation rate is 87%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Iodine adsorption value | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com