System and process for recycling rectification residual liquid generated based on methyl methacrylate

A technology of methyl methacrylate and raffinate, which is applied in the fields of carboxylate preparation, petroleum industry, special dry distillation, etc. It can solve the problems that the cooling water cannot self-circulate, it is difficult to meet the process requirements, and it cannot achieve rapid condensation, etc. Achieve overall cost savings, high recycling rate, and prevent excessive vaporization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

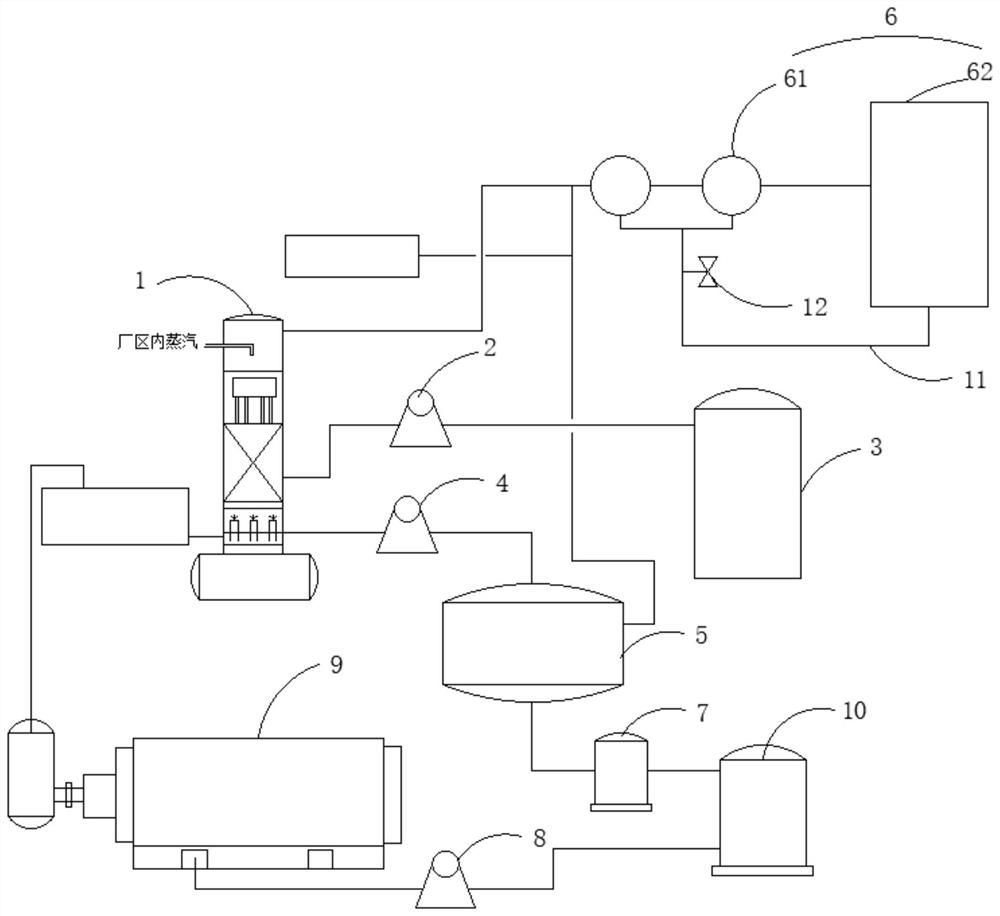

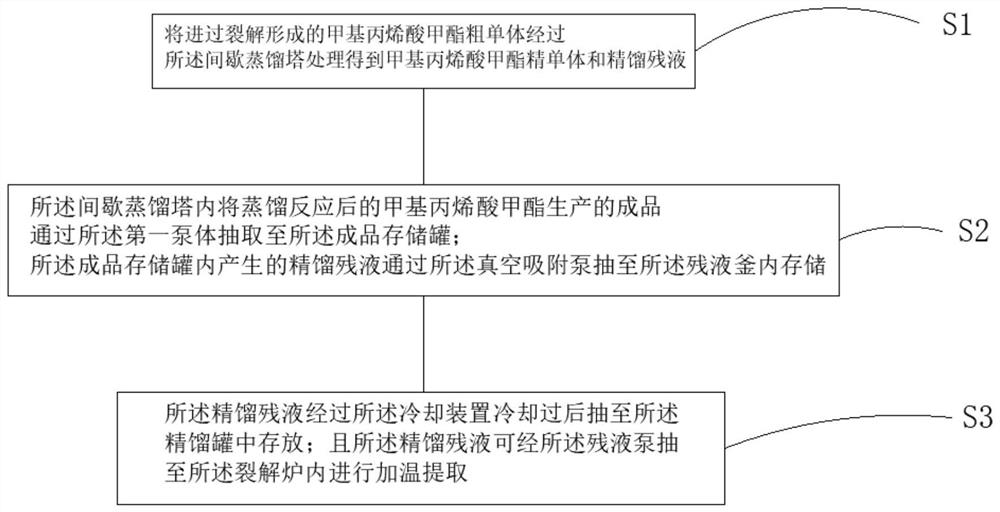

[0034] figure 1 It is the rectification raffinate reuse system and process flow diagram based on methyl methacrylate provided by the specific embodiment of the present invention; figure 2 It is a flow block diagram of the rectification raffinate reuse system and process based on methyl methacrylate provided in the specific embodiment of the present invention; Figures 1 to 2 shown. The invention provides a rectification raffinate reuse system based on methyl methacrylate,

[0035] It includes a batch distillation tower 1 for distilling methyl methacrylate, a first pump body 2, a finished product storage tank 3, a vacuum adsorption pump 4, a raffinate kettle 5, a cooling device 6, a rectification tank 7, a raffinate pump 8, Cracking furnace 9, and fuel storage tank 10;

[0036] Batch distillatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com