Waterproof female shoes and processing technology thereof

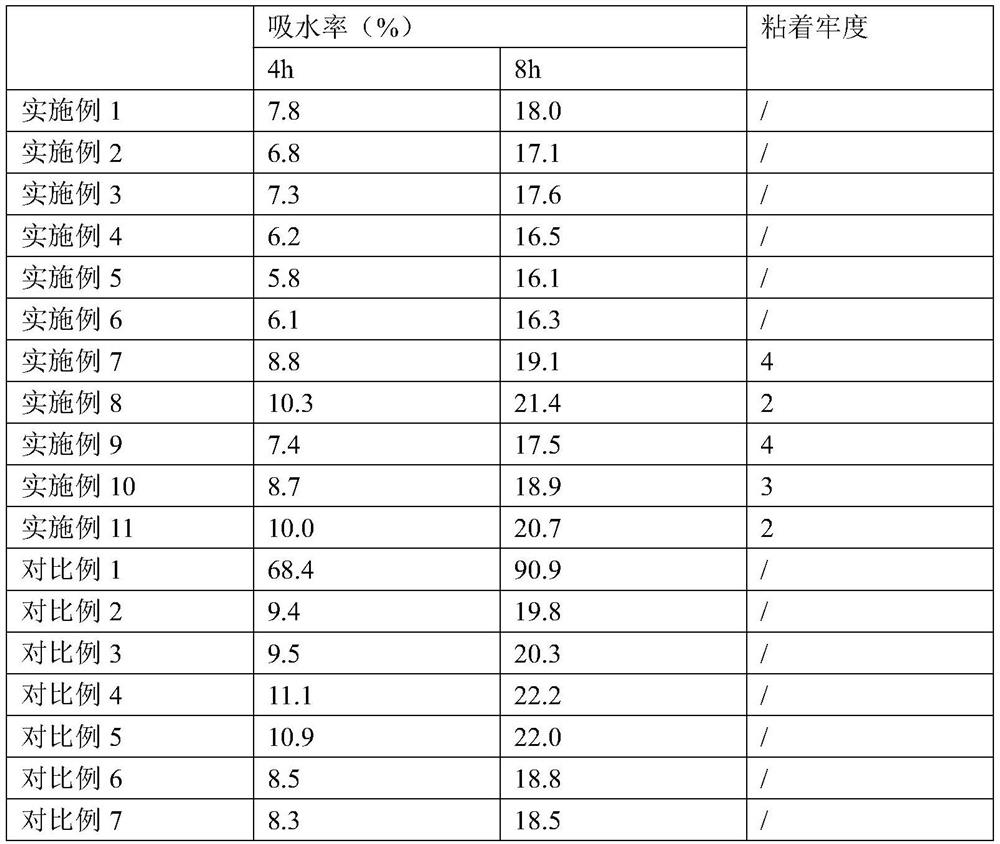

A technology for women's shoes and waterproof finishing, applied in the field of shoes, can solve the problems of affecting the comfort of wearing shoes, poor waterproof effect, infiltration into the interior of shoes, etc., and achieve the effect of improving waterproof effect, improving interface bonding fastness, and reducing water absorption rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The application discloses a waterproof women's shoe and its processing technology. The processing technology includes the following steps:

[0037] S1. Preparation of waterproof finishing agent; first mix polyurethane resin and solvent absolute ethanol, then add butyl stearate and calcium oleate, after stirring for 15 minutes at 40°C, add 5-amino-1-mercaptopentane and The catalyst is triethylaluminum, the temperature is raised to 60°C, and the reaction is stirred for 0.5h to obtain a waterproof finishing agent;

[0038] S2. Shoe upper finishing: pad the shoe upper in the waterproof finishing agent prepared in S1, the pressure is 1.0 MPa, and the liquid retention rate is 65%. After drying, the shoe upper is kept at 80°C for 2 hours, and then cooled to room temperature;

[0039] S3. Molding of women's shoes; cutting and shaping the uppers sorted in S2, and sewing them with the soles to obtain finished women's shoes.

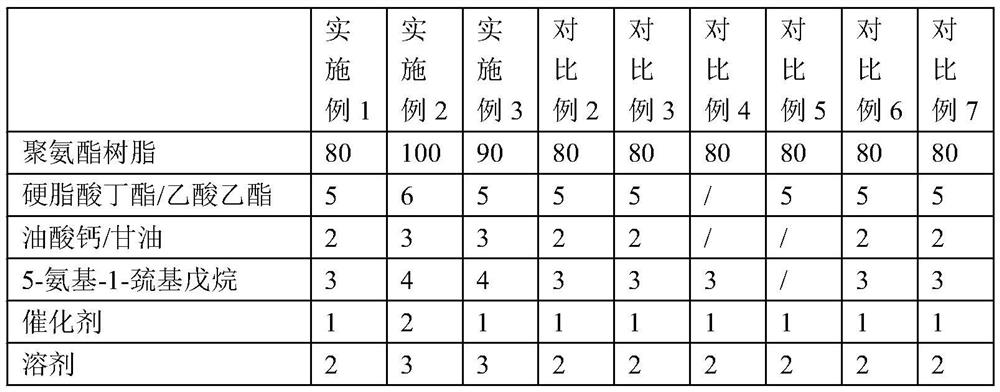

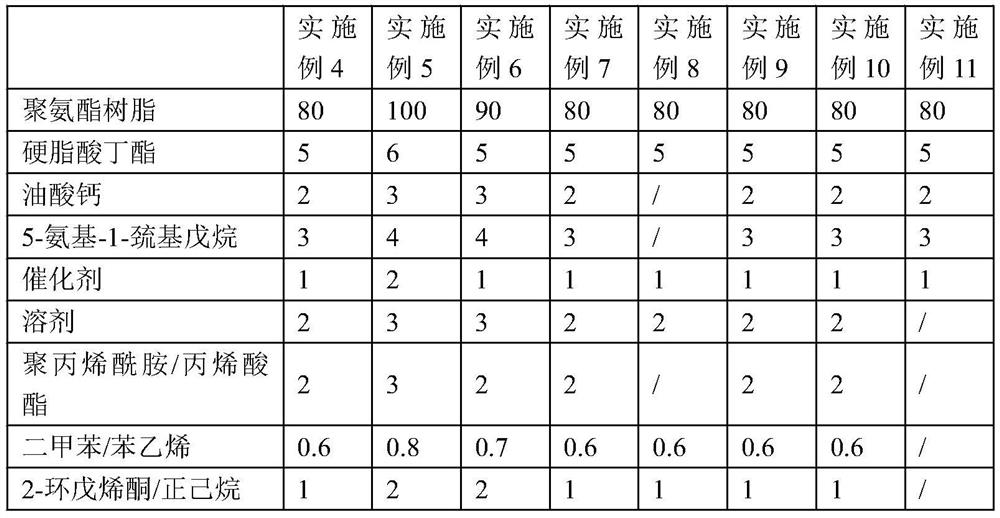

[0040] The content of each component is shown in Tab...

Embodiment 2

[0042] The application discloses a waterproof women's shoe and its processing technology. The processing technology includes the following steps:

[0043] S1. Preparation of waterproof finishing agent; first mix polyurethane resin and solvent absolute ethanol, then add butyl stearate and calcium oleate, stir at 50°C for 20min, then add 5-amino-1-mercaptopentane and The catalyst is triethylaluminum, the temperature is raised to 70°C, and the reaction is stirred for 1 hour to obtain a waterproof finishing agent;

[0044] S2. Finishing of shoe uppers; padding the shoe uppers in the waterproof finishing agent prepared in S1, the pressure is 1.5MPa, and the liquid retention rate is 75%. After drying, the shoe uppers are kept at 100°C for 2.5 hours, and Cool to room temperature;

[0045] S3. Molding of women's shoes; cutting and shaping the uppers sorted in S2, and sewing them with the soles to obtain finished women's shoes.

[0046] The content of each component is shown in Table...

Embodiment 3

[0048] The application discloses a waterproof women's shoe and its processing technology. The processing technology includes the following steps:

[0049] S1. Preparation of waterproof finishing agent; first mix polyurethane resin and solvent absolute ethanol, then add butyl stearate and calcium oleate, stir at 45°C for 18min, then add 5-amino-1-mercaptopentane and The catalyst is triethylaluminum, the temperature is raised to 65°C, and the reaction is stirred for 0.8h to obtain a waterproof finishing agent;

[0050] S2. Shoe upper finishing: pad the shoe upper in the waterproof finishing agent prepared in S1, the pressure is 1.2MPa, and the liquid retention rate is 70%. After drying, the shoe upper is kept at 90°C for 2 hours, and then cooled to room temperature;

[0051] S3. Molding of women's shoes; cutting and shaping the uppers sorted in S2, and sewing them with the soles to obtain finished women's shoes.

[0052] The content of each component is shown in Table 1 below....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com