Aluminum casting mold suitable for flywheel shell manufacturing

A technology for casting aluminum molds and flywheel shells, which is applied in the direction of manufacturing tools, casting molds, and casting mold components. It can solve the problems of hollowing at the edge joints, sticking of the mold opening, and affecting processing, so as to facilitate rapid mold opening and removal. The effect of complete molding of materials and finished products and simple overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

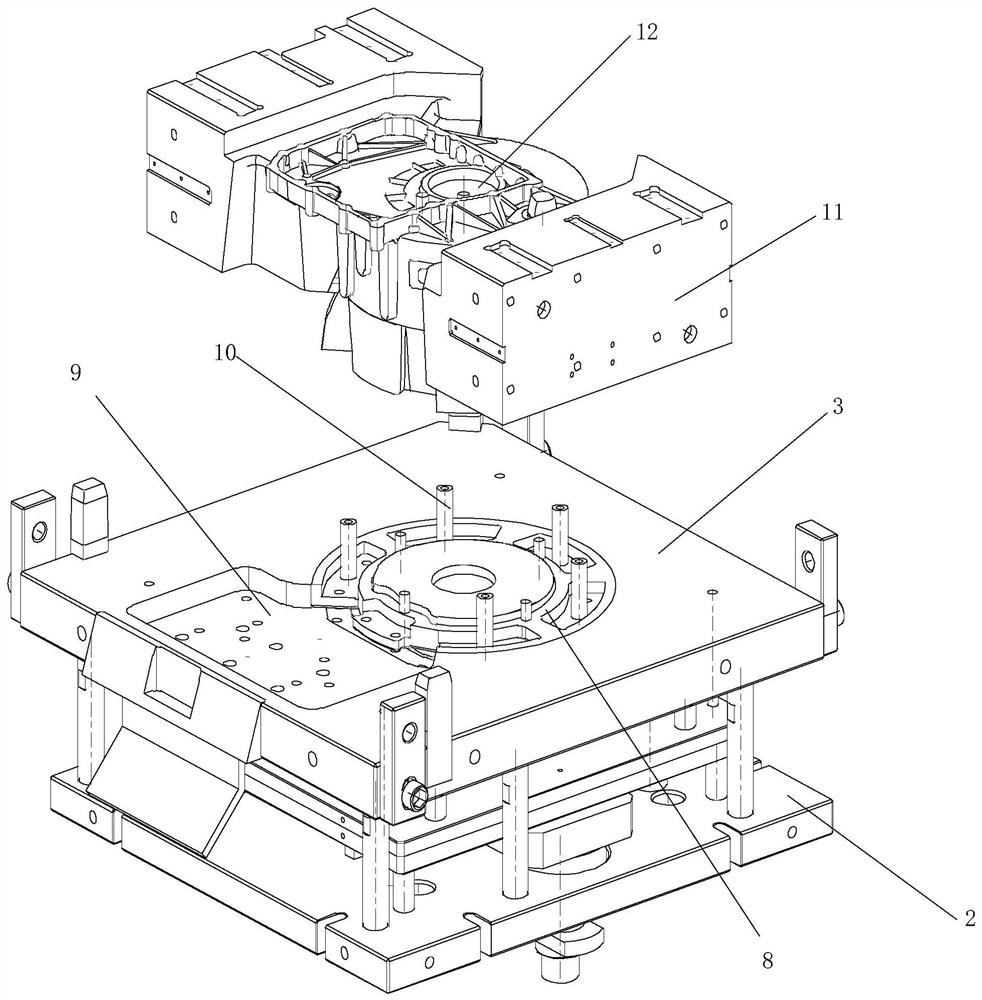

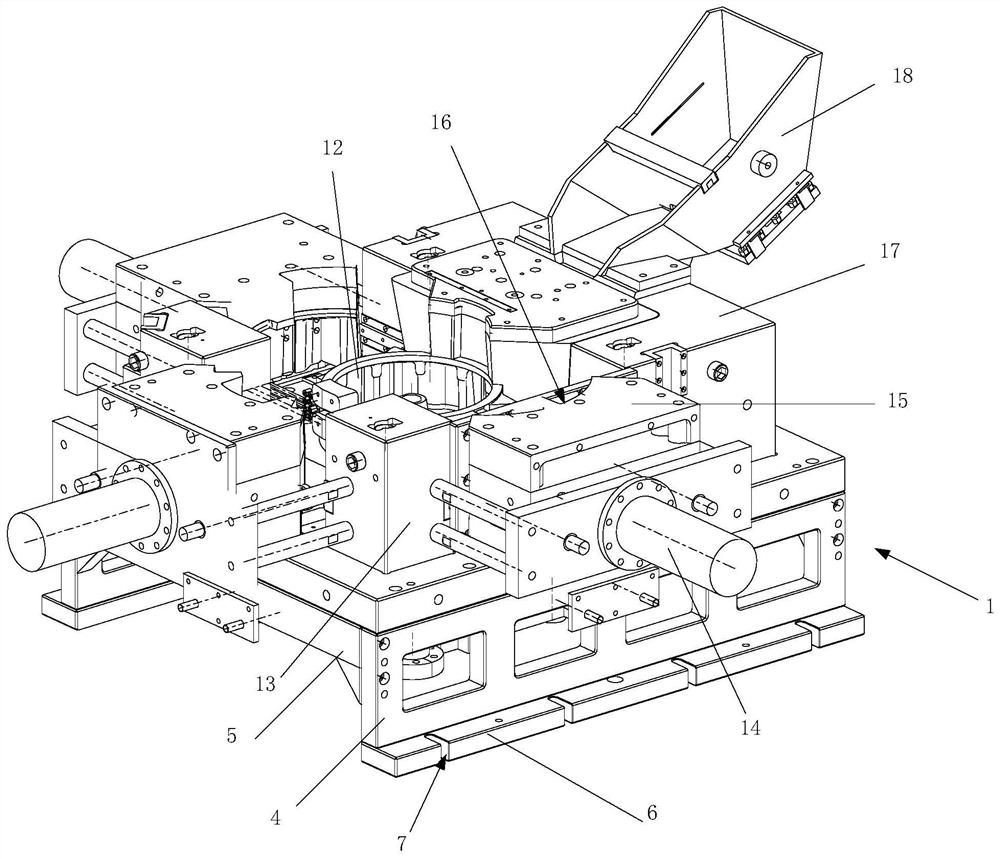

[0021] The invention provides a cast aluminum mold suitable for manufacturing a flywheel housing. The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings, so as to make it easier to understand and grasp.

[0022] Such as Figures 1 to 2 The cast aluminum mold suitable for manufacturing flywheel housings shown includes a mold base 1 , which is different in that: in order to facilitate the stable assembly of subsequent devices, the mold base 1 is provided with a bearing plate 2 . At the same time, in order to facilitate subsequent processing and molding, the inner and outer surfaces of the flywheel housing can be formed simultaneously. A lower mold device 3 is arranged on the carrier plate 2 , and an upper mold device is arranged on the lower mold device 3 . Moreover, considering that the tight combination of the lower mold device 3 and the upper mold device can be satisfied during processing, and an extern...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com