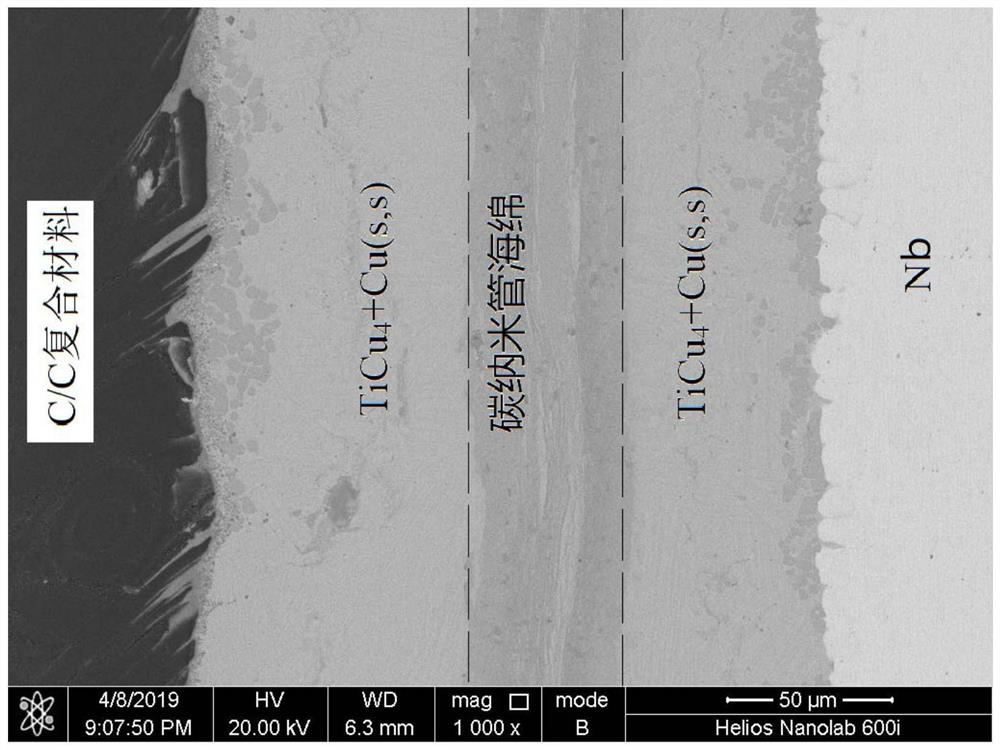

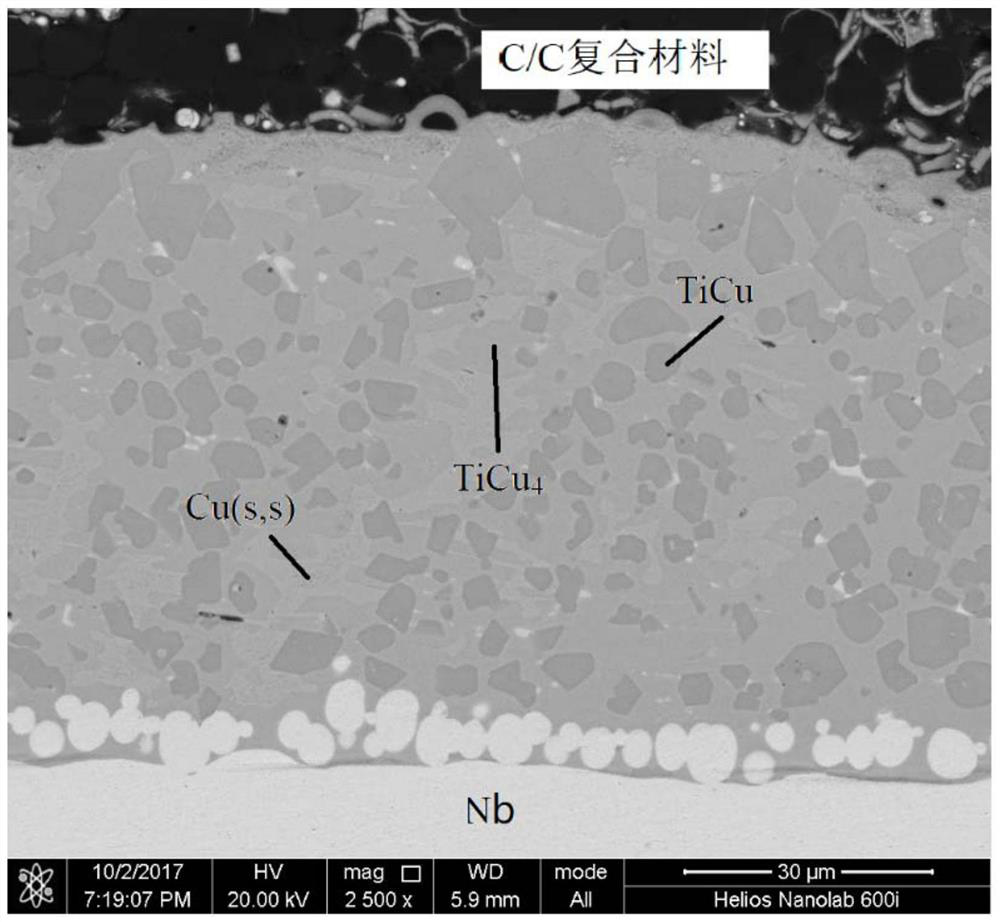

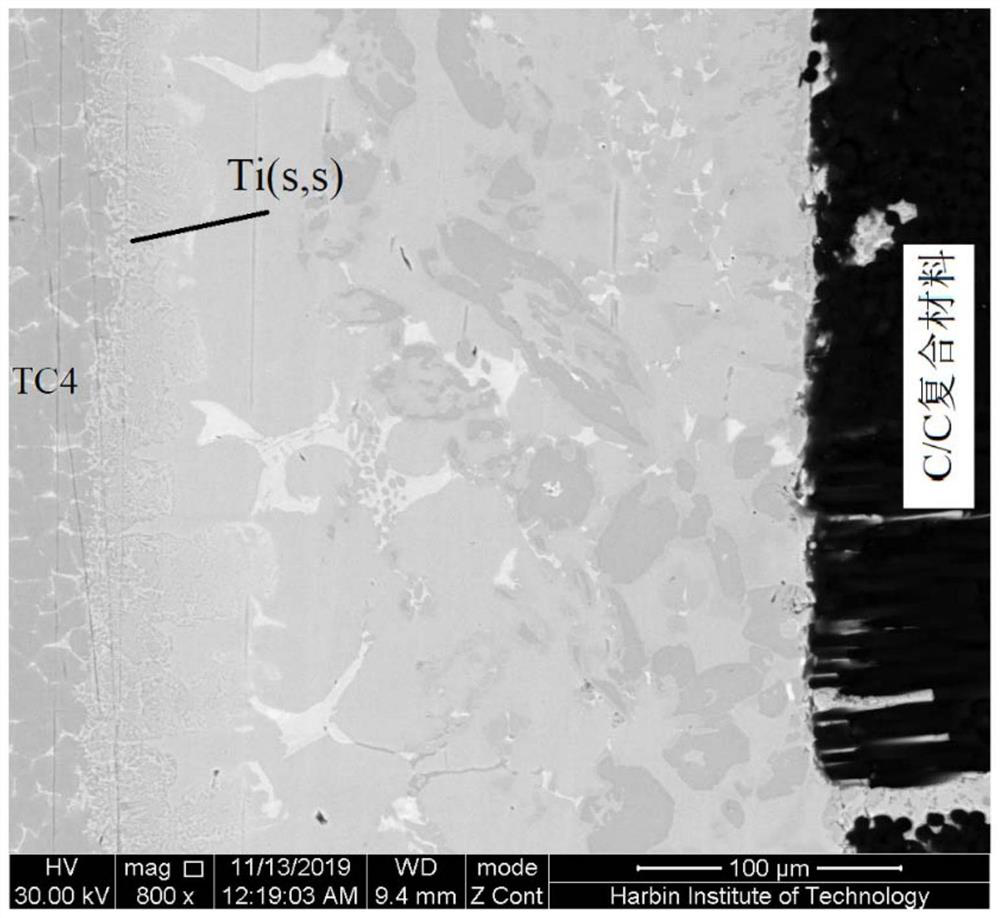

A method for brazing dissimilar materials assisted by a carbon nanotube sponge intermediate layer

A carbon nanotube sponge, dissimilar material technology, applied in auxiliary devices, welding equipment, manufacturing tools, etc., can solve problems such as low strength, and achieve the effect of enhancing brazing seam performance, excellent mechanical properties, and improving joint strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0027] Embodiment 1: The method for assisted brazing of dissimilar materials in the carbon nanotube sponge intermediate layer of the present embodiment is carried out according to the following steps:

[0028] Step 1: Mix the carbon nanotube powder with a strong acid solution, and then perform ultrasonic cleaning at a constant temperature of 60°C to obtain a suspension;

[0029] Step 2, dispersing the suspension obtained in step 1 into deionized water to obtain a mixed solution, then vacuum filtration of the mixed solution to obtain a filter cake, then continue to wash the filter cake, and finally peel off the filter cake and the filter membrane;

[0030] Step 3, ultrasonically dispersing the filter cake obtained by stripping in step 2 into absolute ethanol, centrifuging, and retaining the supernatant;

[0031] Step 4, carry out vacuum filtration on the supernatant obtained in step 3, peel off to obtain a filter cake, and finally dry to obtain carbon nanotube sponge;

[0032]...

specific Embodiment approach 2

[0042] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the carbon nanotube powder in step 1 is single-wall carbon nanotube, double-wall carbon nanotube or multi-wall carbon nanotube.

specific Embodiment approach 3

[0043]Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the ratio of the mass of the carbon nanotube powder described in step 1 to the volume of the strong acid solution is (10-200) mg: (10-30) mL .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com