Degradable environment-friendly membrane material as well as preparation method and application thereof

A kind of membrane material, environmental protection technology, applied in applications, other household appliances, chemical instruments and methods, etc., can solve the problems of low impact strength, damage to the ecological balance of nature, poor mechanical properties, etc., achieve high tensile strength, improve Good use value and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

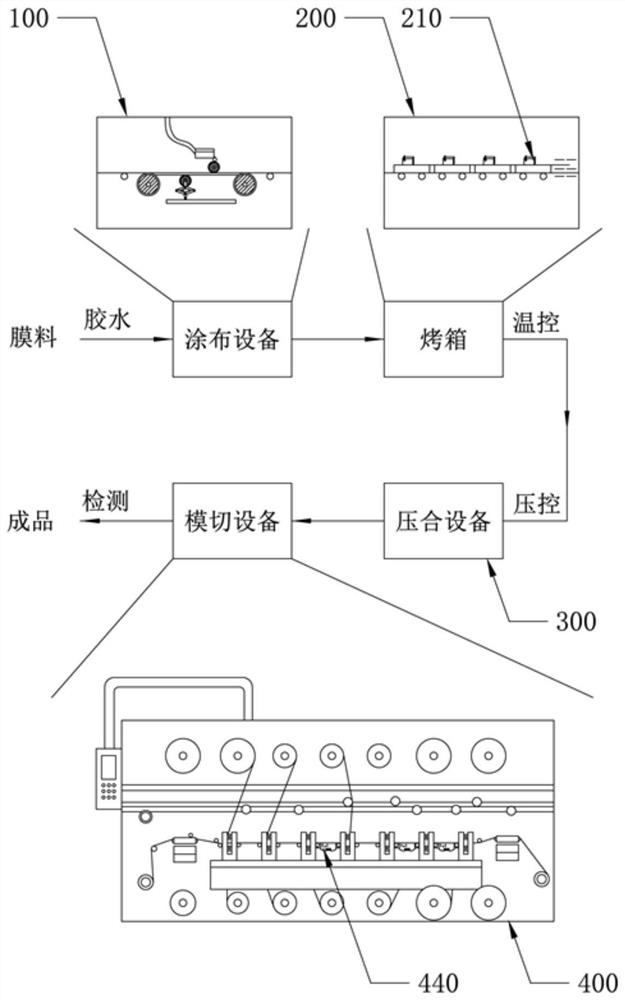

[0050] Another aspect of the present invention provides the preparation method of above-mentioned degradable film material, comprises the following steps:

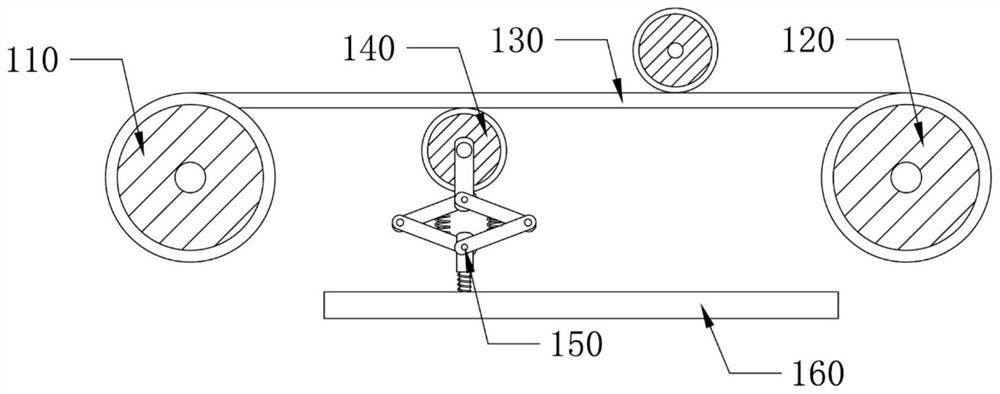

[0051] (1) Coating: get the PLA film, coat the above-mentioned glue on the PLA film, and set aside;

[0052] (2) Baking: Baking the PLA film treated in step (1), the baking process goes through 7 temperature sections in turn, and the 7 temperature sections are 80±5°C, 90±5°C, 110±5°C 5°C, 120±5°C, 100±5°C, 90±5°C, 60±5°C, the time for the PLA film to stay in each temperature range is 5-10 seconds, and the PLA film containing the glue layer is prepared;

[0053] (3) Pressing: attaching a layer of PLA film to the surface of the glue layer of the PLA film containing the glue layer prepared in step (2), and then pressing to obtain the degradable film material.

[0054] Wherein, the coating amount of glue in step (1) is 0.1g-15g / cm 2 , the preferred coating amount is 0.5g-10g / cm 2 . In step (1), when coating the above glue ...

Embodiment 1

[0073] Embodiment 1: the preparation of degradable environmental protection membrane material

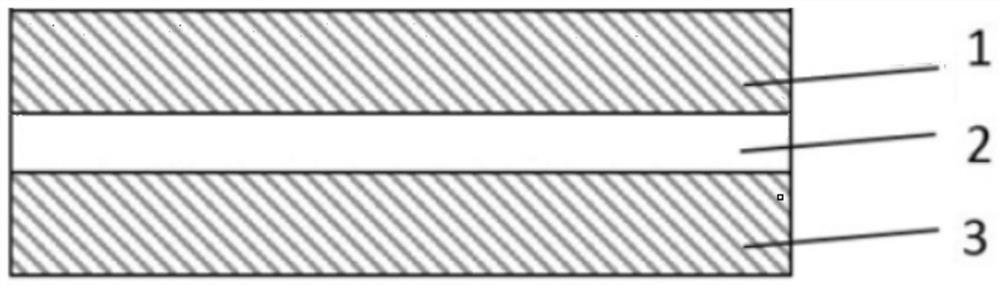

[0074] A degradable environmental-friendly film material, which contains PLA layer, glue layer and PLA layer in sequence; the glue layer includes 24 parts by weight of toluene, 27 parts of ethyl acetate, 46 parts of acrylic resin, and 0.1 parts of carbon nanotubes. share.

[0075] The preparation method of the glue is as follows: the components toluene, ethyl acetate, acrylic resin, and carbon nanotubes are mixed, and then filtered twice under a pressure of 2 kg. Get glue.

[0076] The thickness of the PLA layer is 0.01mm; the thickness of the film material is 0.04mm.

[0077] The preparation method of the above-mentioned degradable environmental protection membrane material comprises the following steps:

[0078] (1) Coating: take the PLA film, and coat the above glue on the PLA film, the coating amount of the glue is 0.2g / cm 2 , when the above-mentioned glue is coated on the P...

Embodiment 2

[0081] Embodiment 2: the preparation of degradable environmental protection film material

[0082] A degradable environmental-friendly film material, which contains PLA layer, glue layer and PLA layer in sequence; the glue layer includes 25 parts by weight of toluene, 27 parts of ethyl acetate, 45 parts of acrylic resin, and 0.4 parts of carbon nanotubes. share.

[0083] The preparation method of the glue is: mix the components of toluene, ethyl acetate, acrylic resin, and carbon nanotubes, and then filter 3 times under a pressure of 3.0 kg. Prepare the glue.

[0084] The thickness of the PLA layer is 0.01mm, and the thickness of the film material is 0.03mm.

[0085] combined reference figure 1 , the preparation method of the above-mentioned degradable environmental protection film material, comprising the following steps:

[0086] (1) Coating: take the PLA film, and coat the above glue on the PLA film, and the coating amount of the glue is 0.3g / cm 2 , when the above-ment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com