Chemical foaming low-density alkali slag foam concrete and preparation method thereof

A foamed concrete and chemical foaming technology, applied in the field of building materials, can solve problems such as poor durability, change, and a large amount of garbage, and achieve the effects of short setting time, rapid strength development, and good thermal insulation and sound insulation performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

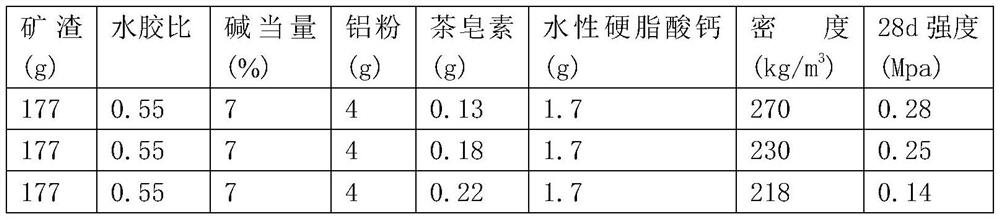

[0045] Embodiment 1: A kind of chemically foamed low-density alkali slag foam concrete is composed of the following components by mass percentage: slag: 56%; water glass: 16%; sodium hydroxide: 2%; chemical blowing agent: 1 %; foam stabilizer: 0.057%; water: 12%; surfactant: 1.0%.

[0046] Among them, the modulus of water glass is 3.08, the water content is 57.1%, Na 2 O content is 9.1%, SiO 2 The content is 27.19%. The chemical foaming agent is aluminum powder, which is prepared into aluminum powder-water-surfactant suspension during use. The foam stabilizer is tea saponin. Surfactant is aqueous calcium stearate, and the mass fraction is 50%. The slag is ground water-quenched blast furnace slag.

[0047] The preparation method is as follows:

[0048] S1: Disperse aluminum powder in water and stir for 5 minutes, then add water-based calcium stearate and mix and stir for 5 minutes to prepare water-aluminum powder-water-based calcium stearate suspension;

[0049] S2: Add ...

Embodiment 2

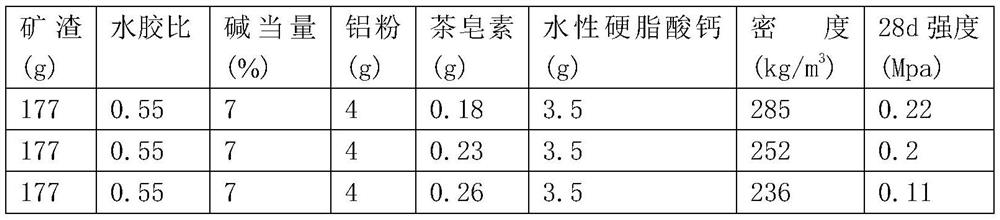

[0052] Embodiment 2: A kind of chemically foamed low-density alkali slag foam concrete is composed of the following components by mass percentage: slag: 58%; water glass: 20%; sodium hydroxide: 4%; chemical foaming agent: 2 %; foam stabilizer: 0.082%; water: 18%; surfactant: 1.2%.

[0053] Among them, the modulus of water glass is 3.08, the water content is 57.1%, Na 2 O content is 9.1%, SiO 2 The content is 27.19%. The chemical foaming agent is aluminum powder, which is prepared into aluminum powder-water-surfactant suspension during use. The foam stabilizer is tea saponin. Surfactant is aqueous calcium stearate, and the mass fraction is 50%. The slag is ground water-quenched blast furnace slag.

[0054] The preparation method is as follows:

[0055] S1: Disperse aluminum powder in water and stir for 5 minutes, then add water-based calcium stearate and mix and stir for 5 minutes to prepare water-aluminum powder-water-based calcium stearate suspension;

[0056] S2: Add ...

Embodiment 3

[0059]Embodiment 3: A kind of chemically foamed low-density alkali slag foam concrete is composed of the following components by mass percentage: slag: 57%; water glass: 18%; sodium hydroxide: 3%; chemical foaming agent: 1.3% %; foam stabilizer: 0.057%; water: 15%; surfactant: 1.1%.

[0060] Among them, the modulus of water glass is 3.08, the water content is 57.1%, Na 2 O content is 9.1%, SiO 2 The content is 27.19%. The chemical foaming agent is aluminum powder, which is prepared into aluminum powder-water-surfactant suspension during use. The foam stabilizer is tea saponin. Surfactant is aqueous calcium stearate, and the mass fraction is 50%. The slag is ground water-quenched blast furnace slag.

[0061] The preparation method is as follows:

[0062] S1: Disperse aluminum powder in water and stir for 5 minutes, then add water-based calcium stearate and mix and stir for 5 minutes to prepare water-aluminum powder-water-based calcium stearate suspension;

[0063] S2: Ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com