Method for preparing light insulating brick from refined manganese slag and forming production line of light insulating brick

A technology for insulating bricks and a production line, which is applied in the field of preparing lightweight insulating bricks and using refined manganese slag to prepare lightweight insulating bricks, achieving the effects of reducing the area occupied by stacking, improving thermal insulation performance and fire resistance, and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0053] Table 1 Specific examples of insulation bricks

[0054]

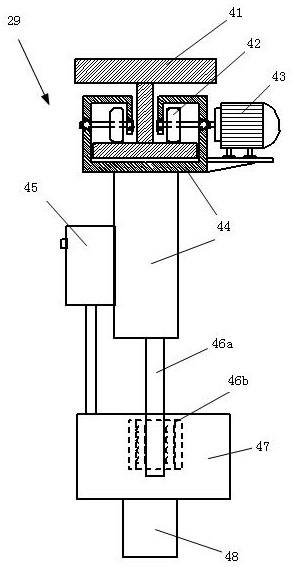

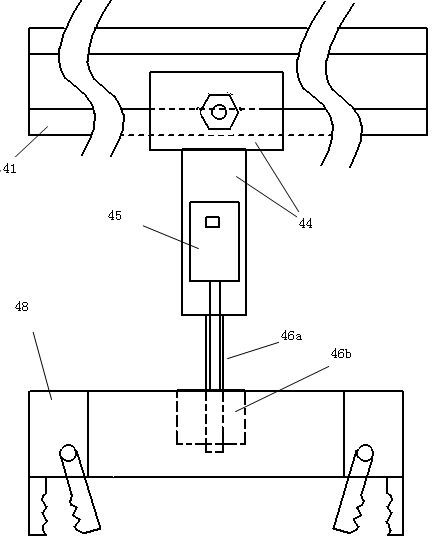

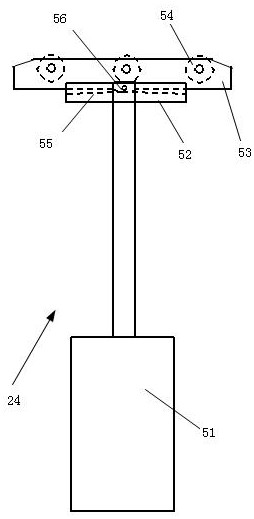

[0055] A production line for forming insulation bricks, figure 1It is a structural schematic diagram of the insulating brick forming production line in the present invention. The insulation brick molding production line includes a mixer 10, the outer periphery of the mixer 10 is provided with a ring gear, the ring gear meshes with the gear on the output shaft of the rotating motor 11, the rotating motor 11 drives the body of the mixer 10 to rotate, and the two sides of the driving mixer 10 are respectively provided with raw materials The entrance and the slurry outlet, the slurry outlet is provided with a slurry outlet 12, and a crane is provided below the slurry outlet 12 of the mixer. The crane includes two beams 15, and the two beams 15 are rolled and provided with the slurry moving along the The bucket 16 and the driving roller 13 move along the driving track 14. The slurry bucket rollers 17 are arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com