Method for preparing methyl methacrylate by taking methyl acetate as raw material

A technology of methyl methacrylate and methyl acrylate, applied in the field of preparing methyl methacrylate, can solve the problems of high cost and large investment of methyl methacrylate, and achieve the advantages of cheap sources, increased economic benefits and abundant sources. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

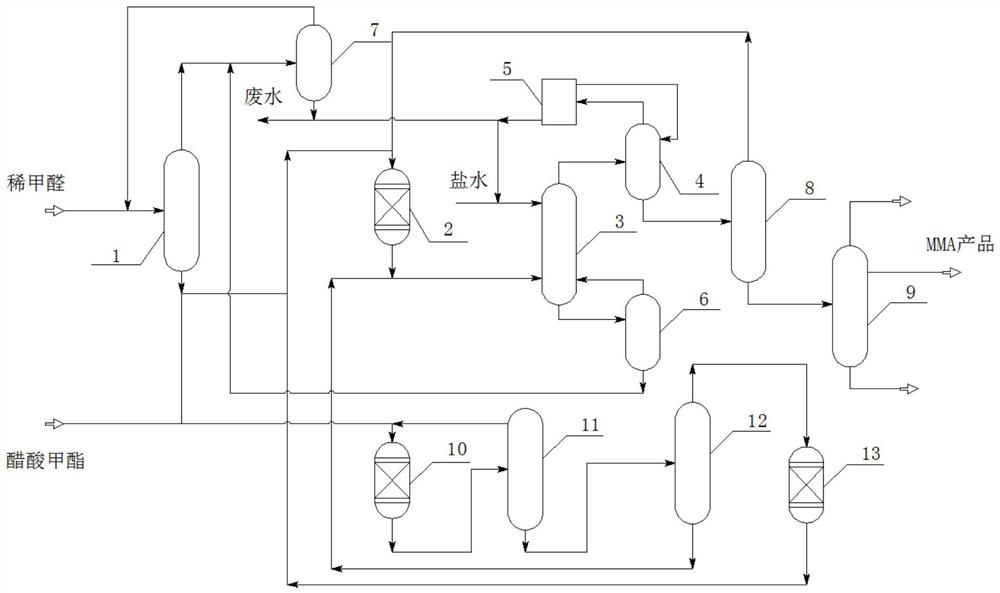

[0024] Present embodiment is that the technological process of preparing methyl methacrylate with methyl acetate as raw material sees attached figure 1 , the specific method and experimental results are as follows:

[0025] The molded catalysts were loaded into the condensation reactor one, the condensation reactor two and the hydrogenation reactor respectively, and were all sprayed with H before use. 2 Activation, the activation conditions are: temperature 200°C, normal pressure, gas space velocity 500h -1 , Activation time 6h. Using existing conventional aldol condensation reaction catalysts in the art, as long as the technical effects of the aldol condensation of methyl acetate and formaldehyde and the aldol condensation of methyl propionate and formaldehyde in this embodiment can be achieved.

[0026] 37% industrial-grade dilute formaldehyde enters the formaldehyde concentration unit 1 for concentration, and a part of the concentrated formaldehyde is mixed with methyl ac...

Embodiment 2

[0035] The test and analysis methods are the same as in Example 1, the reaction temperature of condensation reactor one 10 is changed to 350°C, and the reaction temperature of condensation reactor two 2 is changed to 370°C.

[0036] The experimental results are: the conversion rate of methyl acetate is 45%, the selectivity of methyl propionate is 94%; the conversion rate of methyl propionate is 36%, and the selectivity of methyl methacrylate is 87%.

Embodiment 3

[0038] The test and analysis methods are the same as those in Example 1, the pressure of condensation reactor one 10 is changed to 3.0 bar, and the pressure of condensation reactor two 2 is changed to 2.0 bar.

[0039] The experimental results are: the conversion rate of methyl acetate is 62%, the selectivity of methyl propionate is 82%; the conversion rate of methyl propionate is 28%, and the selectivity of methyl methacrylate is 91%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com