Preparation method of butyl rubber

A butyl rubber and slurry technology, applied in the rubber field, can solve the problems of product quality fluctuation and production cost increase, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The invention provides a kind of preparation method of butyl rubber, comprises the following steps:

[0036] a) mixing a monoolefin with a solvent to obtain a mixed solution;

[0037] b) dissolving the slurry stabilizer in diene to obtain a slurry stabilizer solution;

[0038] c) mixing and reacting the mixed solution, the slurry stabilizer solution and the catalyst solution to form butyl rubber;

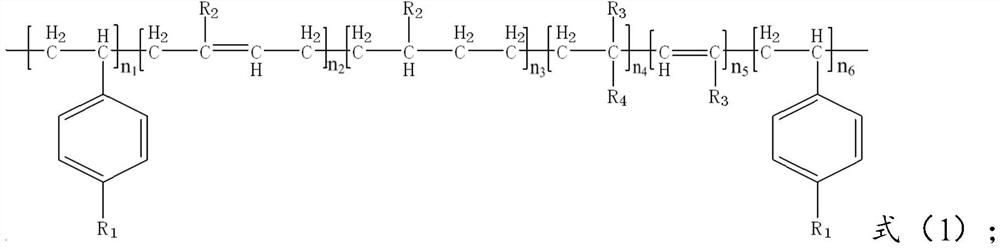

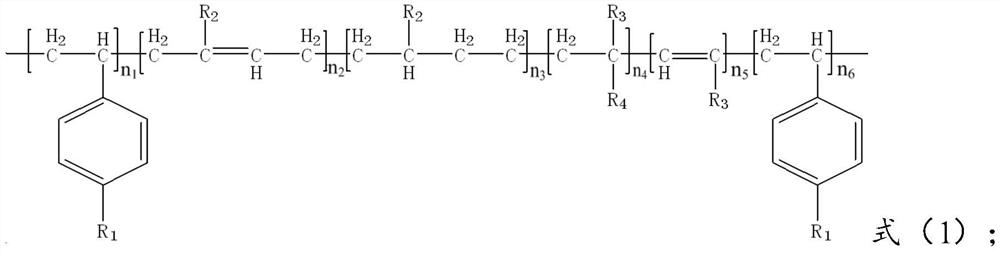

[0039] Described slurry stabilizer has structure shown in formula (1):

[0040]

[0041] in,

[0042] R 1 , R 2 , R 3 and R 4 each independently selected from H, C1-C15 alkyl, vinyl, halogen, hydroxyl, halomethyl, haloethyl or α-methylvinyl;

[0043] Polymerization n 1 4~2000, n 2 0~2000, n 3 0~2000, n 4 0~2000, n 5 0~2000, n 6 It is 0~2000.

[0044] The present invention introduces the slurry stabilizer shown in formula (1) in the preparation process, which can effectively reduce the polymerization speed of cationic living polymerization, improve the dispers...

Embodiment 1

[0090] S1. At -70°C, weigh 22.5g of isobutene and add it to 127.5g of monochloromethane to obtain a mixed solution.

[0091] S2. Add the polymer represented by formula (1-1) into isoprene to obtain a 6.3 wt% slurry stabilizer solution.

[0092] S3. Add 1.07 g of the slurry stabilizer solution in step S2 to the mixed solution in step S1, and lower the temperature to -97.5° C. to obtain a reactant solution.

[0093] S4, take by weighing the normal hexane solution (mass fraction of 10%) of 0.2g ethyl aluminum sesquichloride, join in the monochloromethane solution (mass fraction of 0.025wt%) of 10gHCl, mix well, and in-97.5 Aging at ℃ for 30 min to obtain a catalyst solution.

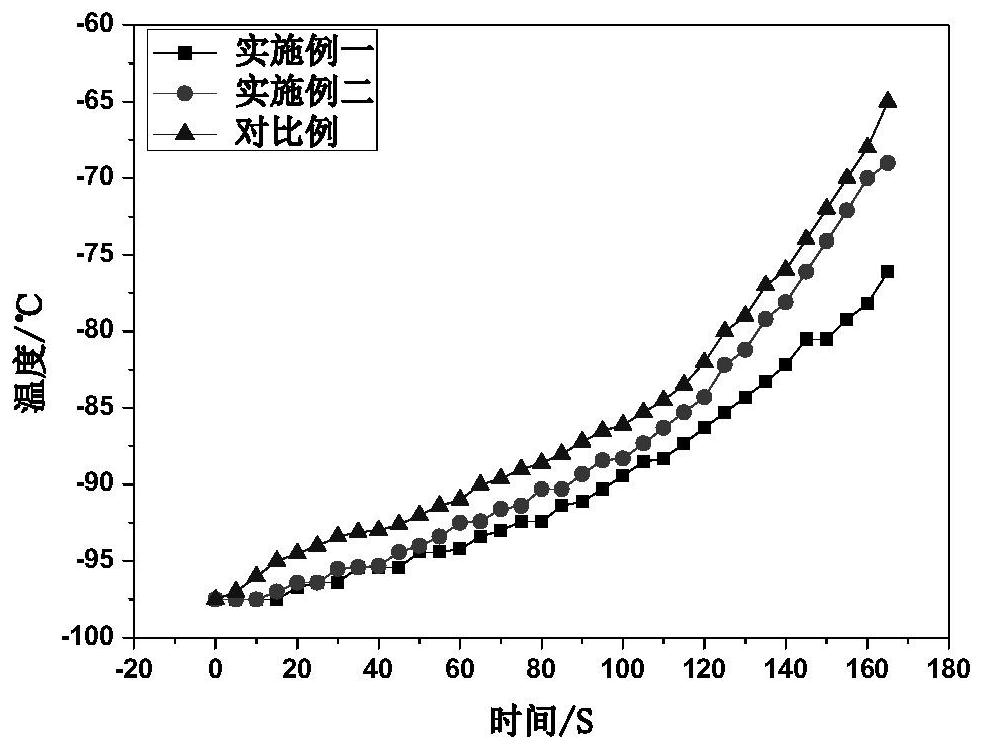

[0094] S5. Add the catalyst solution in step S4 into the reactant solution in step S3, and react at -97.5° C. for 20 minutes. During the polymerization process, the temperature rises slowly, and the obtained slurry is uniformly dispersed in the form of particles.

[0095] S6. Add 2 g of ethanol to termin...

Embodiment 2

[0097] S1. At -70°C, weigh 20 g of isobutene and add it to 113.5 g of monochloromethane to obtain a mixed solution.

[0098] S2. Add the polymer represented by formula (1-2) into isoprene to obtain a 4.4 wt% slurry stabilizer solution.

[0099] S3. Add 1.36 g of the slurry stabilizer solution in step S2 to the mixed solution in step S1, and lower the temperature to -97.5° C. to obtain a reactant solution.

[0100] S4. Weigh 0.15g of a n-hexane solution of diethylaluminum chloride (20% by mass fraction), add it into a chloromethane solution of 6gHCl (0.020wt% by mass fraction), mix well, and store at -97.5°C aging for 20 min to obtain a catalyst solution.

[0101] S5. Add the catalyst solution in step S4 into the reactant solution in step S3, and react at -97.5° C. for 10 min. During the polymerization process, the temperature rises slowly, and the obtained slurry is uniformly dispersed in the form of particles.

[0102] S6. Add 2 g of ethanol to terminate the reaction, move...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com