Flexible-elastic shape-stabilized temperature-controlled multifunctional phase-change material and preparation method thereof

A phase-change material and multi-functional technology, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of limited performance of the obtained materials, complicated preparation process, difficulty in mass production, etc., and achieve good shape stability and phase change prevention The effect of material leakage ability, wide range of sources, and large latent heat of phase change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A soft-elastic shape-setting temperature-controlling multifunctional phase change material, including the following raw materials: n-docosane 50g, FG19013g, INFUSE TM OBC 9530 12g and dicumyl peroxide 0.5g.

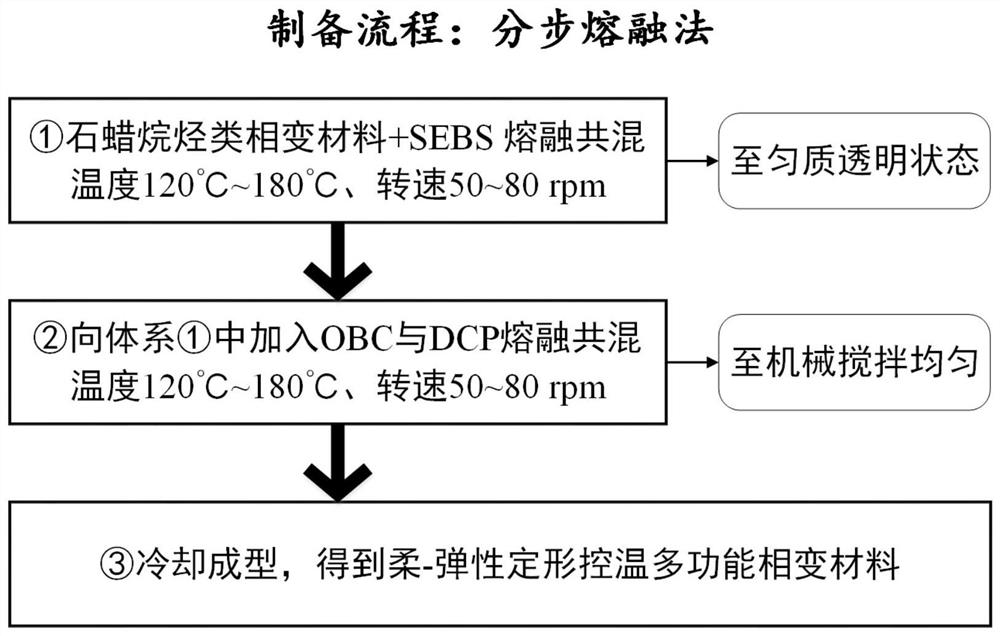

[0033] The preparation method of the above-mentioned flexible-elastic shape-setting temperature-controlling multifunctional phase change material comprises the following steps:

[0034] (1) Stir and melt blend n-docosane and FG1901 at a temperature of 120°C for 30 minutes at a stirring speed of 50 rpm until the system is uniformly mixed and appears transparent, and blend 1 is obtained;

[0035] (2) Add INFUSE to the blend obtained in step (1) TM OBC 9530 and dicumyl peroxide were stirred and melt-blended at 160° C. for 40 minutes at a stirring speed of 50 rpm to obtain blend 2;

[0036] (3) Cast the blend II obtained in step (2), and cool to obtain a flexible-elastic shape-setting temperature-controlling multifunctional phase change material.

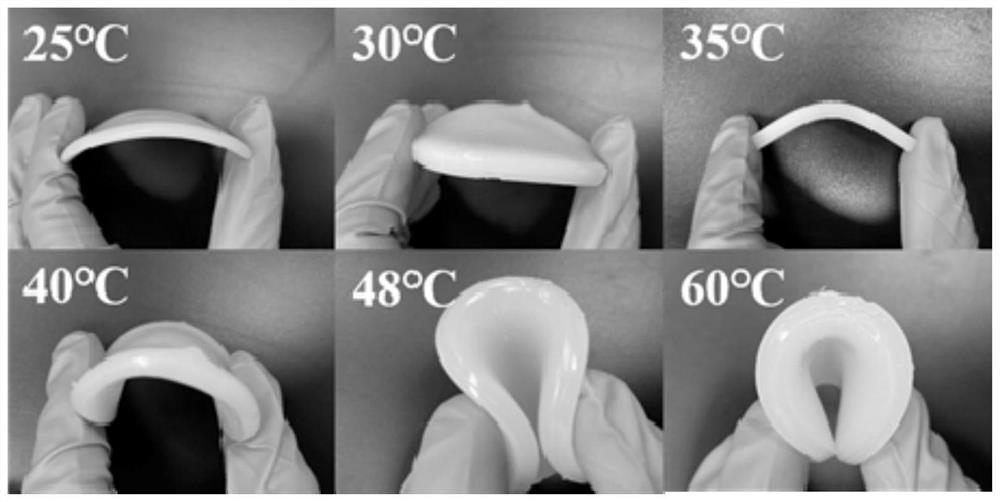

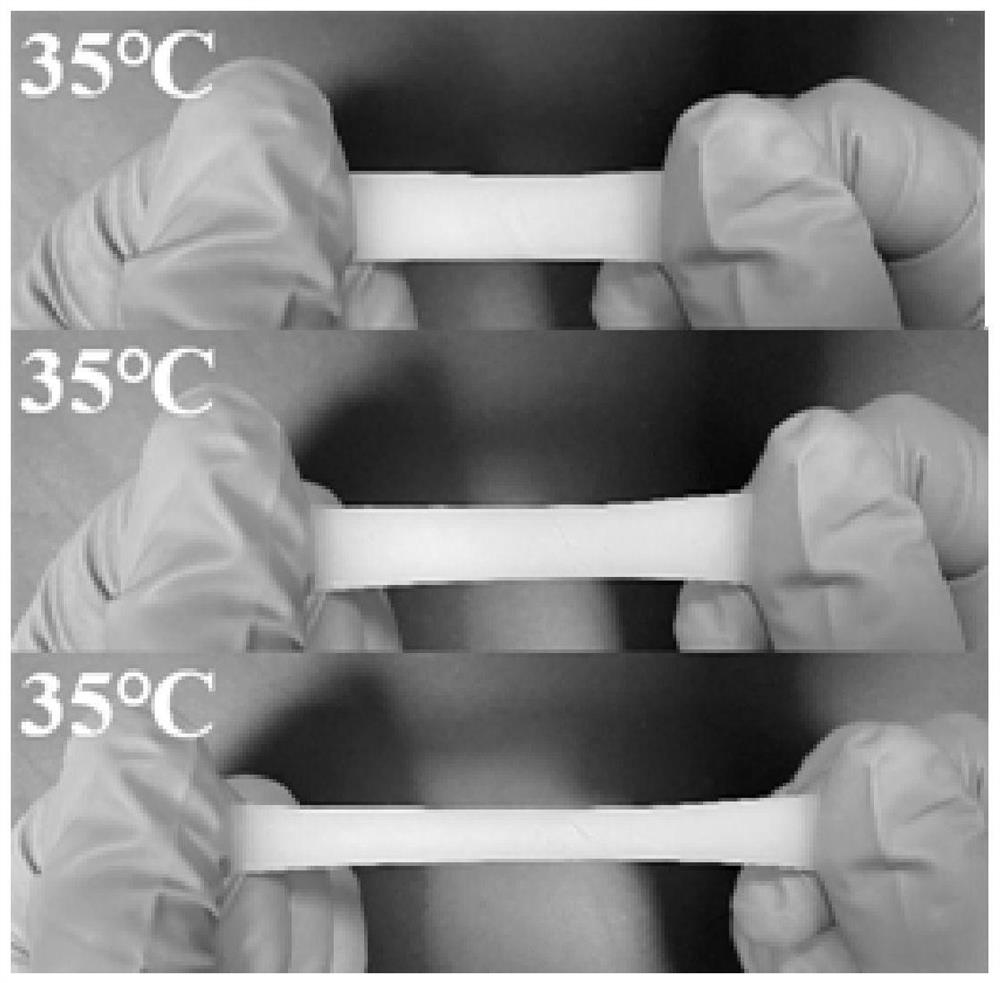

[0037] The soft-e...

Embodiment 2

[0039] A soft-elastic shape-setting temperature-controlling multifunctional phase change material, including the following raw materials: n-docosane 50g, FG19013g, INFUSE TM OBC 9530 12.5g and dicumyl peroxide (DCP) 0.5g.

[0040] The preparation method of the above-mentioned flexible-elastic shape-setting temperature-controlling multifunctional phase change material comprises the following steps:

[0041] (1) Stir and melt blend n-docosane and FG1901 at a temperature of 120°C for 30 minutes at a stirring speed of 60 rpm until the system is uniformly mixed and appears transparent to obtain blend 1;

[0042] (2) Add INFUSE to the blend obtained in step (1) TM OBC 9530 and dicumyl peroxide (DCP), were stirred and melt-blended at a temperature of 160°C for 40 minutes, and the stirring speed was 60 rpm to obtain a blend 2;

[0043] (3) Cast the blend II obtained in step (2), and cool to obtain a flexible-elastic shape-setting temperature-controlling multifunctional phase change ...

Embodiment 3

[0046] A soft-elastic shape-setting temperature-controlling multifunctional phase change material, including the following raw materials: OP44E phase change wax 50g, G16522g, INFUSE TM OBC 9530 13g and dicumyl peroxide (DCP) 0.5g.

[0047] The preparation method of the above-mentioned flexible-elastic shape-setting temperature-controlling multifunctional phase change material comprises the following steps:

[0048] (1) Stir and melt blend OP44E phase-change wax and G1652 at 120°C for 30 minutes at a stirring speed of 80 rpm until the system is evenly mixed and appears transparent to obtain blend 1;

[0049] (2) Add INFUSE to the blend obtained in step (1) TM OBC 9530 and dicumyl peroxide (DCP), were stirred and melt-blended at 160° C. for 40 minutes, and the stirring speed was 80 rpm to obtain blend 2;

[0050] (3) Cast the blend II obtained in step (2), and cool to obtain a flexible-elastic shape-setting temperature-controlling multifunctional phase change material.

[005...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com