Control method for improving macroscopic quality and segregation index of high-carbon chromium bearing steel

A technology of high carbon chromium bearing steel and control method, applied in the field of metallurgical production of bearing steel, can solve the problems of low structure quality and high degree of segregation, and achieve the effect of high matching degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

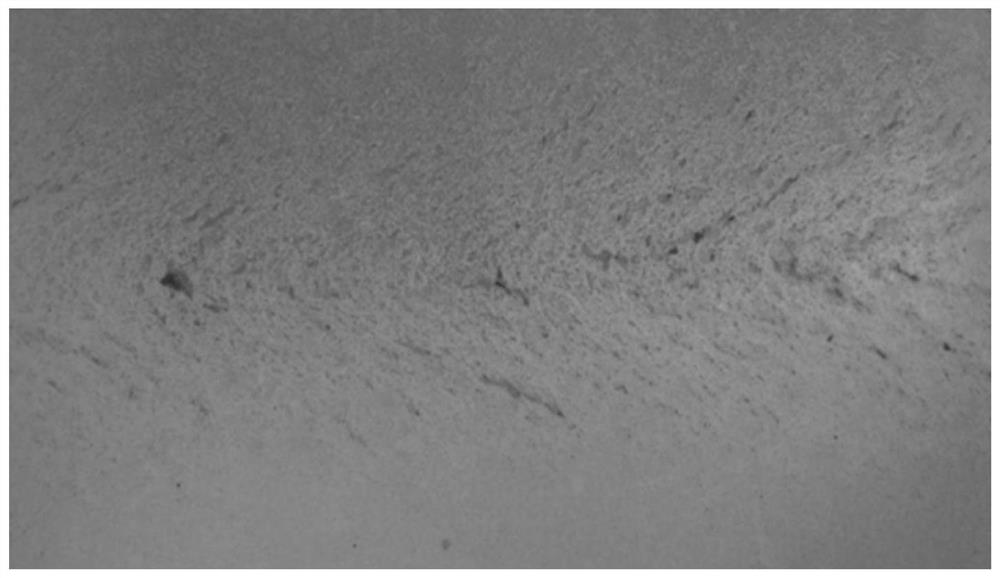

Image

Examples

Embodiment 1

[0029] This embodiment provides a control method for improving the low-magnification quality and segregation index of high-carbon chromium bearing steel, including a smelting process control method and a continuous casting process control method.

[0030] The primary smelting stage adopts high-drawing carbon end point control, and the C content in tapping is not less than 0.35%. During the tapping process, aluminum ingots are added at one time according to the C component at the end point to complete the deep deoxidation of precipitation, creating a favorable time for purifying molten steel in the refining stage; in the refining stage Control the white slag retention time to not less than 30 minutes, the vacuum circulation time to 20 minutes, and the argon soft blowing time to not less than 30 minutes; the continuous casting stage adopts a low superheat and high casting speed method, the superheat is controlled at 25-35 ° C, and the casting speed is 0.57 m / min; the secondary co...

Embodiment 2

[0032] This example provides a specific control method for the smelting process—the initial smelting stage and the refining stage of the converter or electric furnace—in the control method for improving the low-magnification quality and segregation index of high-carbon chromium bearing steel.

[0033] The specific control methods in the initial refining stage are as follows:

[0034] Put 105 tons of pig iron, molten iron or steel material into the converter or electric furnace, use high carbon end point control, when the molten steel temperature is ≥ 1600 ℃ and the C content is ≥ 0.35%, the oxidized slag is released to prevent slag, during the tapping process The amount of slag lowered is not more than 2kg / t, the number of furnaces at the tapping port is less than 120 furnaces, and the slag blocking operation is performed when the furnace body is at 90° to prevent the oxide slag from being carried out during the tapping process. Carbon, slag making, aluminum ingots and alloys ...

Embodiment 3

[0056] This example provides specific control methods for continuous casting process—casting speed and temperature, slab cooling, electromagnetic stirring and light reduction—in the control method for improving the low-magnification quality and segregation index of high-carbon chromium bearing steel.

[0057] The continuous casting of this embodiment adopts 5 machines and 5 strands of 250mm×280mm rectangular billet.

[0058] During the continuous casting pouring process, protect the pouring. The ladle nozzle is protected by double argon collars. The molten steel after soft blowing is poured under the protection of argon gas with a flow rate of 20-40L / h to prevent secondary oxidation of molten steel. Argon is blown to the baked tundish before pouring to reduce the residual oxygen content in the tundish, and the crystallizer liquid level fluctuation is controlled within ±3mm to reduce the risk of slag entrainment caused by liquid level fluctuations.

[0059] During the pouring p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com