Spinning method of wool fiber and mint fiber blended yarn

A mint fiber and blended yarn technology, which is applied in fiber opening and cleaning, fiber treatment, yarn, etc., can solve the problems of low production efficiency, poor quality, and high noise of adsorption and impurity removal of blended yarns, so as to improve the preparation efficiency and The effect of preparation quality, long-lasting antibacterial balance, and evenness improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

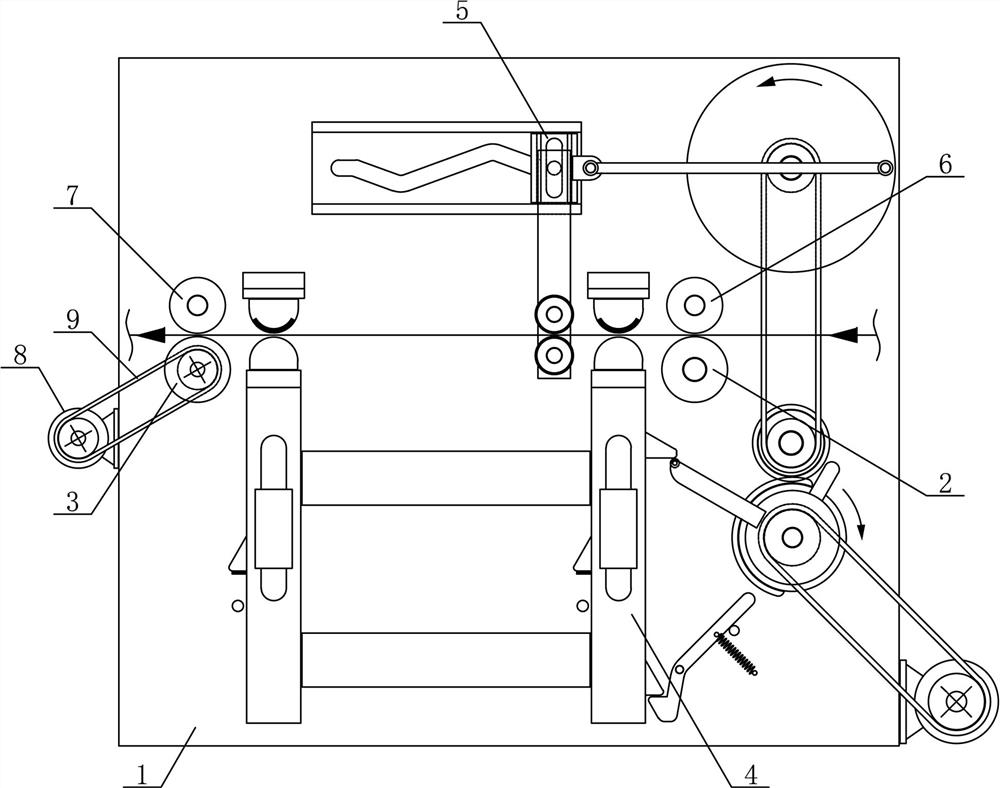

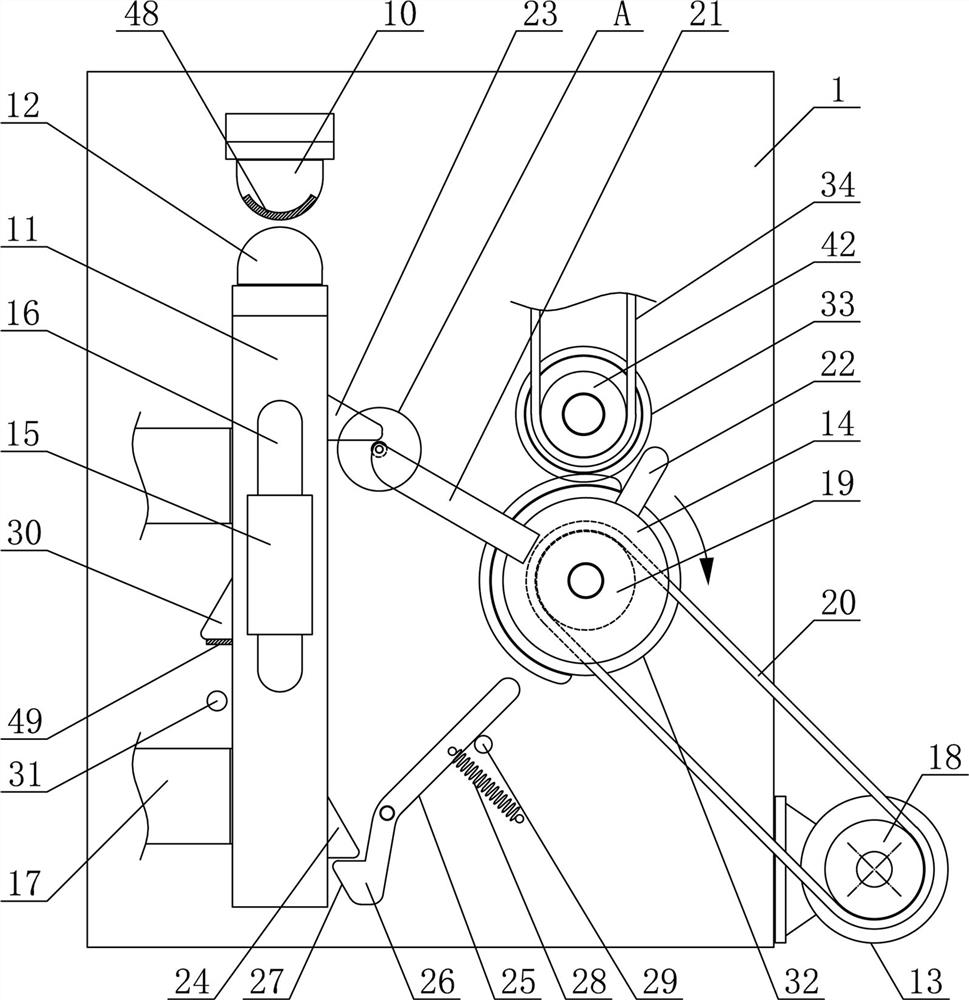

[0029]In order to further describe the present invention, the specific implementation of a spinning method of wool fiber and mint fiber blended yarn will be further described below with reference to the accompanying drawings. The following examples are for explaining the present invention and the present invention is not limited to the following examples.

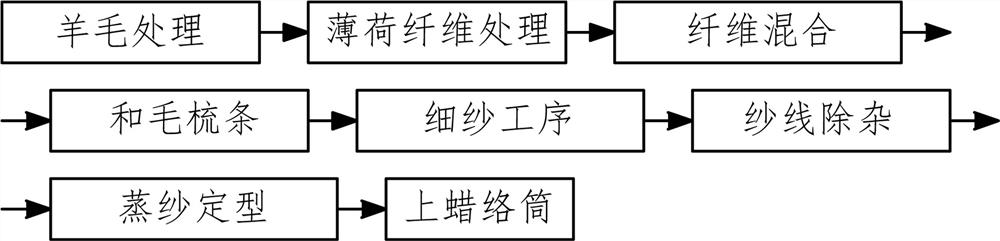

[0030]Such asfigure 1 As shown, the spinning method of wool fiber and mint fiber blended yarn of the present invention includes the following steps:

[0031]Step 1: Wool treatment, select the raw wool used to prepare the blended yarn, clean the raw wool, remove the stains in the raw wool, and then dry the raw wool;

[0032]Step 2: Mint fiber processing, select the mint fiber used to prepare the blended yarn, select the mint fiber with a fineness of 2.5dtex and a length of 65mm, and open the mint fiber on the textile opening equipment freely;

[0033]Step 3: Fiber mixing, mix the raw wool processed in Step 1 and the mint fiber processed in St...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com