Sample target processing system of matrix-assisted laser desorption ionization time-of-flight mass spectrometer

A technology of time-of-flight mass spectrometry and matrix-assisted laser, which is applied in the preparation of test samples, instruments, analytical materials, etc., can solve problems such as reducing the efficiency of microbial mass spectrometry identification, affecting sample stability, and biological safety issues, and ensuring stability. performance, faster drying, and shorter working steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

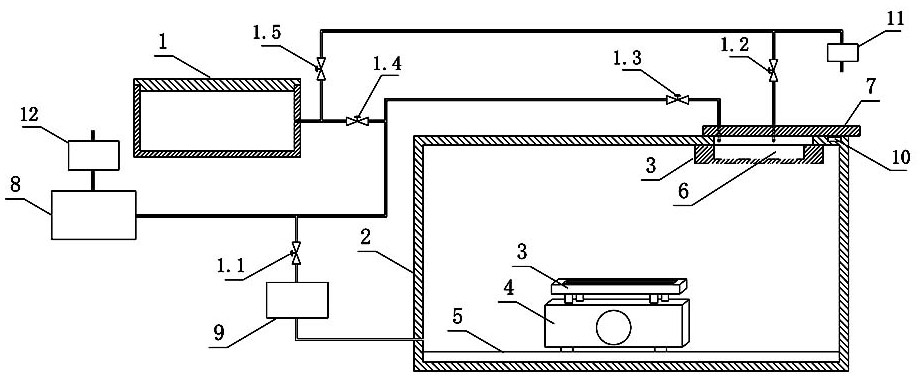

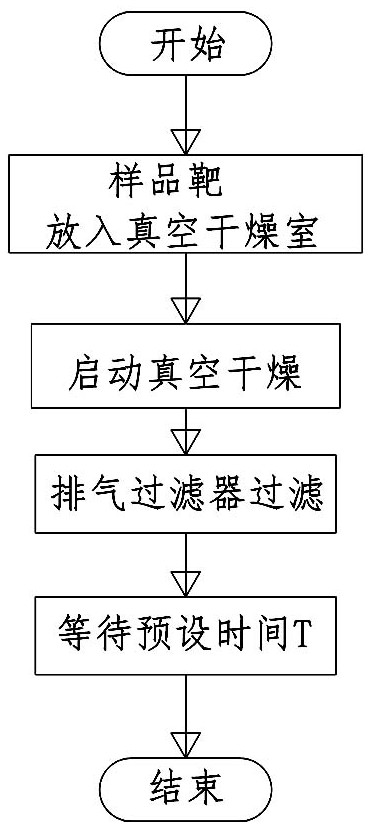

[0021] Such as figure 1 , 2 As shown, the matrix-assisted laser desorption ionization time-of-flight mass spectrometer sample target processing system of the present invention includes a vacuum drying chamber 1 and a vacuum sampling chamber 2; the vacuum drying chamber 1 is used to dry the sample to be detected on the sample target , the vacuum sampling chamber 2 is provided with a moving part for carrying the sample target groove 3, and the sample target groove 3 is used to carry the sample target; the mobile part is preferably selected as a remote control rail car 4, and the remote control rail car 4 is arranged in the vacuum sampling chamber On the track 5 in the chamber 2, the remote control rail car 4 is provided with a lifting mechanism for raising / lowering the sample target groove 3; a transition chamber 6 is provided at the sampling port of the vacuum sampling chamber 2; the transition chamber 6 The formation process is as follows: when the sample target groove 3 move...

Embodiment 2

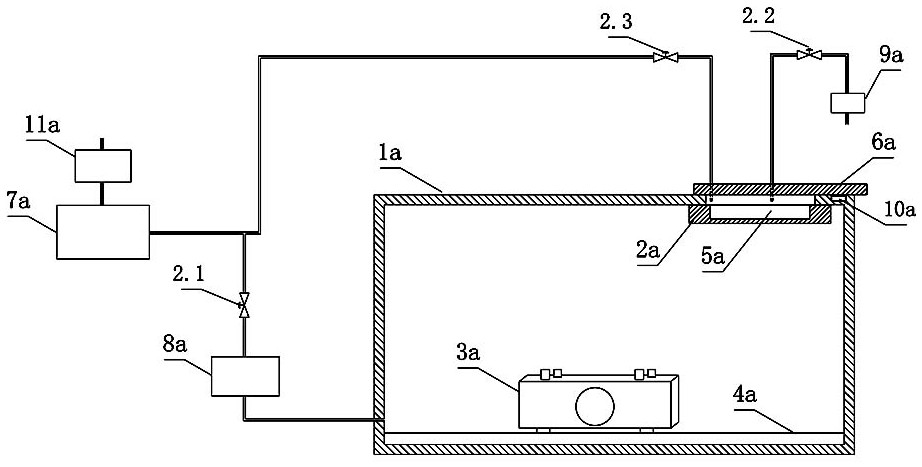

[0028] Such as image 3 , 4 As shown, the matrix-assisted laser desorption ionization time-of-flight mass spectrometer sample target processing system of the present invention includes a vacuum sampling chamber 1a, and a moving part for carrying a sample target groove 2a is arranged in the vacuum sampling chamber 1a, and the sample target The slot 2a is used to carry the sample target; the mobile part is preferably a remote control rail car 3a, and the remote control rail car 3a is set on the inner rail 4a of the vacuum sample chamber 1a, and the remote control rail car 3a is provided with a slot 2a for raising / lowering the sample target The lifting mechanism; located at the sampling port of the vacuum sampling chamber 1a is provided with a transition chamber 5a that doubles as a vacuum drying chamber, that is, the vacuum drying chamber and the transition chamber in this embodiment are the same chamber. In other embodiments of the present invention, the moving part may have o...

Embodiment 3

[0036] Such as Figure 5 As shown, the difference between this embodiment and Embodiment 2 is that two sample inlets are provided on the side wall of the vacuum sampling chamber 1b, and hatches 2.1b and 2.2b are respectively arranged at the two inlets, corresponding to Specifically, two sample target grooves 3.1b, 3.2b are arranged in the vacuum sampling chamber 1b, and the moving part can independently drive any one of the sample target grooves to move. The air inlet of the mechanical pump 4b is divided into two gas paths, one gas path communicates with the molecular pump 6b through the valve 3.1; The transition chambers 5.1b and 5.2b communicate with the atmosphere through the valve 3.4, the valve 3.5 and the intake filter 7b respectively, and the exhaust port of the mechanical pump 4b communicates with the atmosphere through the exhaust filter 8b.

[0037] In order to avoid the time-consuming drying of the sample target in the transition chamber (the vacuum drying chamber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com