Photovoltaic module

A technology of photovoltaic modules and bonding parts, which is applied in the direction of photovoltaic power generation, electrical components, semiconductor devices, etc., can solve the problems of high cost of photovoltaic modules and low reliability of photovoltaic modules, and achieve improved connection reliability, low cost, and favorable output effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Embodiments of the present invention are described in detail below, and the embodiments described with reference to the drawings are exemplary, and embodiments of the present invention are described in detail below.

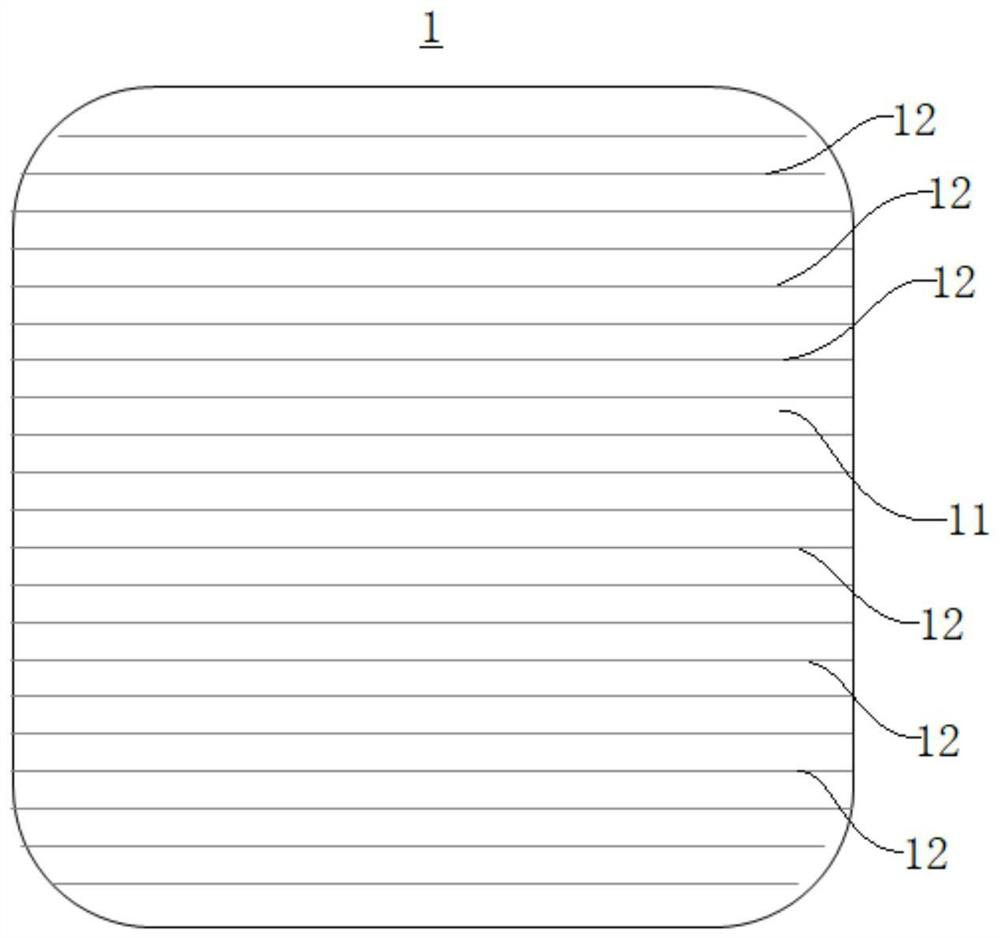

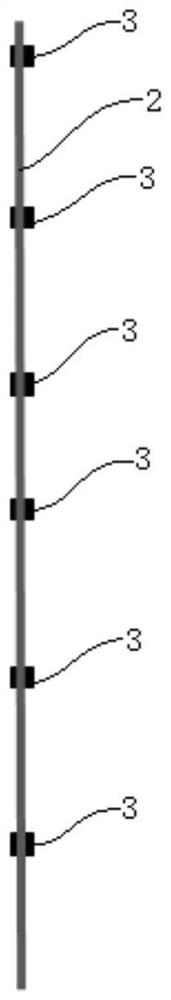

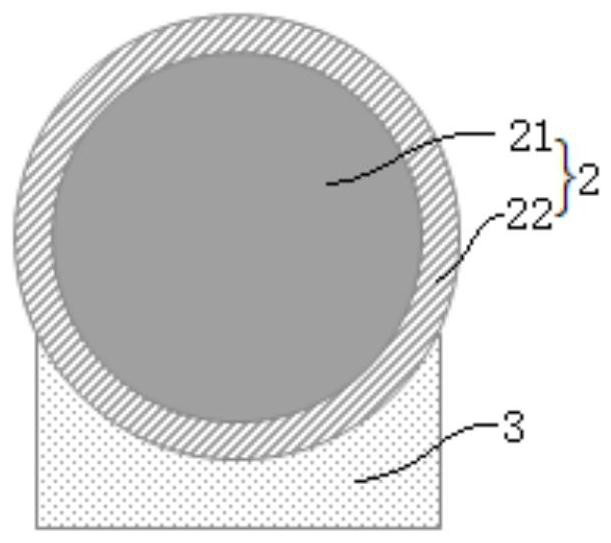

[0045] Refer below Figure 1-Figure 12 A photovoltaic module according to an embodiment of the present invention is described. Photovoltaic modules can be heterojunctions (a special PN junction formed by depositing more than two layers of different semiconductor material films on the same base in sequence. These materials have different energy band gaps. They can be gallium arsenide and the like. compounds, or semiconductor alloys such as silicon-germanium) components. In the following description of the present application, the photovoltaic module is taken as an example for illustration. Of course, those skilled in the art can understand that the photovoltaic module can also be other types of modules, and is not limited to heterojunction modules.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com