SiOC and nitrogen-doped carbon fiber composite negative electrode of lithium battery and preparation method

A nitrogen-doped carbon fiber and lithium battery technology, applied in battery electrodes, negative electrodes, secondary batteries, etc., can solve problems such as difficult processes, improve electrical conductivity and cycle performance, and simplify the sintering process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

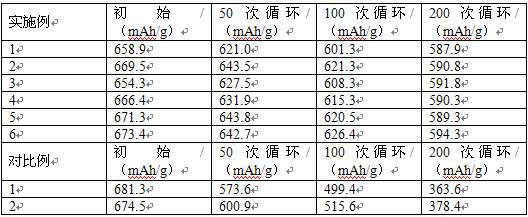

Examples

Embodiment 1

[0045] A method for preparing a lithium battery SiOC@nitrogen-doped carbon fiber composite negative electrode, comprising the following steps:

[0046] S1. Preparation of Al 2 o 3 / polysiloxane composite particles: the parts by weight of KH550 silane coupling agent, absolute ethanol, dilute hydrochloric acid aqueous solution, and porous alumina microspheres are 100 parts, 100 parts, 10 parts, and 30 parts in sequence;

[0047] S11. Add KH550 silane coupling agent into absolute ethanol, then add dilute hydrochloric acid aqueous solution (molar concentration of hydrochloric acid is 0.5mol / L), keep mechanical stirring for 30min to obtain sol;

[0048] S12. Add ammonia water to the sol to adjust the pH of the sol to neutral, add porous alumina microspheres (1-20 μm in size, 50-500 nm in pore size) to fully absorb the sol, filter it, and heat-treat it at 100°C for 90 minutes to get the product Al 2 o 3 / polysiloxane composite particles;

[0049] S2. Preparation of spinning fi...

Embodiment 2

[0054] A method for preparing a lithium battery SiOC@nitrogen-doped carbon fiber composite negative electrode, comprising the following steps:

[0055] S1. Preparation of Al 2 o 3 / Polysiloxane composite particles: the parts by weight of KH550 silane coupling agent, absolute ethanol, dilute hydrochloric acid aqueous solution, and porous alumina microspheres are 150 parts, 200 parts, 30 parts, and 50 parts in sequence;

[0056] S11. Add KH550 silane coupling agent into absolute ethanol, then add dilute hydrochloric acid aqueous solution (the molar concentration of hydrochloric acid is 0.1mol / L), keep mechanical stirring for 30min to obtain a sol;

[0057] S12. Add ammonia water to the sol to adjust the pH of the sol to neutral, add porous alumina microspheres (1-20 μm in size, 50-500 nm in pore size) to fully absorb the sol, filter, and heat-treat at 110°C for 30 minutes to get the product. Al 2 o 3 / polysiloxane composite particles;

[0058] S2. Preparation of spinning f...

Embodiment 3

[0063] A method for preparing a lithium battery SiOC@nitrogen-doped carbon fiber composite negative electrode, comprising the following steps:

[0064] S1. Preparation of Al 2 o 3 / Polysiloxane composite particles: the parts by weight of KH550 silane coupling agent, absolute ethanol, dilute hydrochloric acid aqueous solution, and porous alumina microspheres are 120 parts, 140 parts, 15 parts, and 35 parts in sequence.

[0065] S11. Add KH550 silane coupling agent into absolute ethanol, then add dilute hydrochloric acid aqueous solution (molar concentration of hydrochloric acid is 0.2mol / L), keep mechanical stirring for 30min to obtain sol;

[0066] S12. Add ammonia water to the sol to adjust the pH of the sol to neutral, add porous alumina microspheres (1-20 μm in size, 50-500 nm in pore size) to fully absorb the sol, filter, heat-treat at 110°C for 60 minutes, and obtain Al 2 o 3 / polysiloxane composite particles;

[0067] S2. Preparation of spinning film: the weight ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com