Laying fowl feed and preparation process and application thereof

A production process and technology for egg poultry, applied in the field of egg poultry feed and breeding, can solve the problems of unoptimized adjustment of feed formula, few sources of Chinese herbal medicine, high cost of use, etc., to increase the concentration of available nutrients, improve digestion and utilization efficiency, and improve resistance The effect of sickness and health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

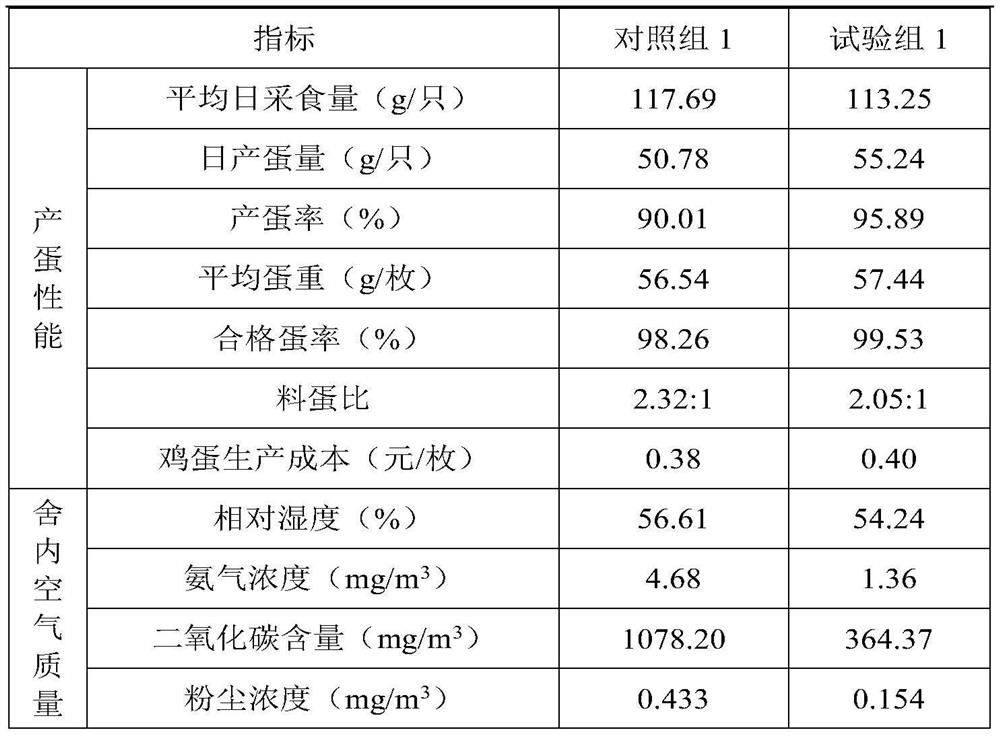

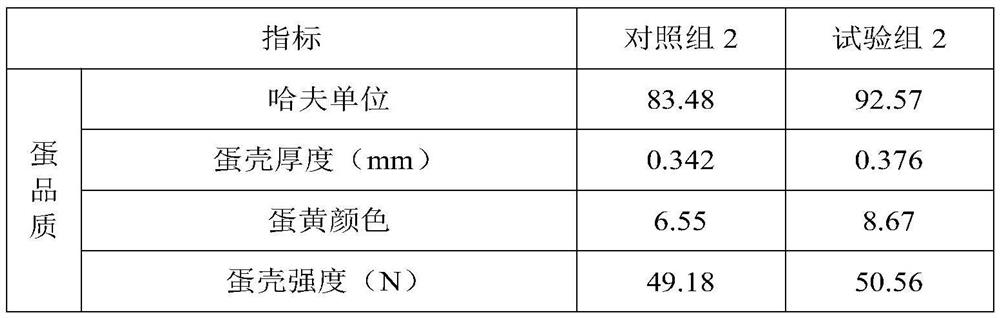

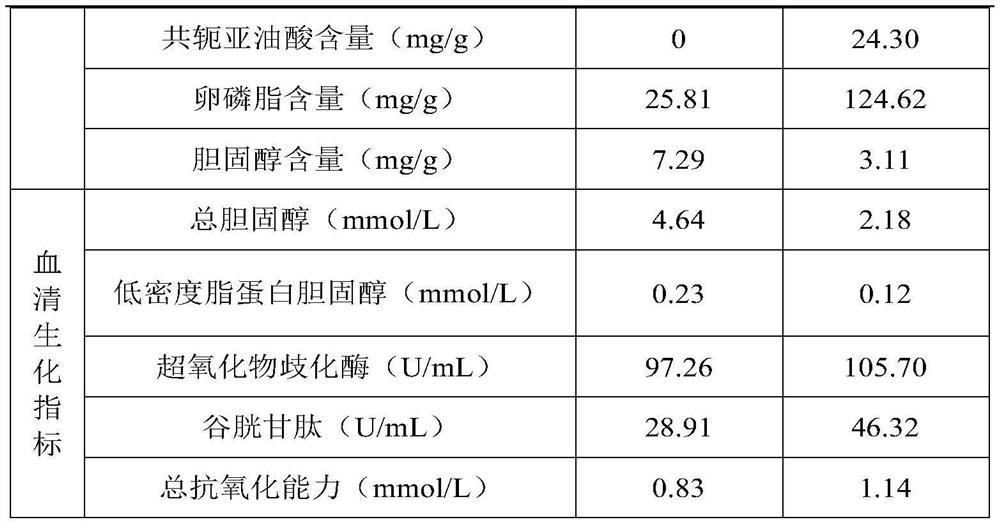

Embodiment 1

[0029] A feed for eggs and poultry, comprising the following raw material components in parts by weight: 55.8 parts of corn, 15 parts of rice bran meal, 4 parts of wheat bran, 12 parts of fermented material, 1.6 parts of conjugated linoleic acid glyceride, 1 part of soybean lecithin powder, 0.9 parts of calcium hydrogen phosphate, 8.4 parts of granular stone powder, 0.3 parts of table salt and 1 part of premix (a general product on the market).

[0030] The fermented material includes the following raw material components, basic raw material, composite bacterial liquid and water, and the basic raw material includes the following raw material components in parts by weight, 65 parts of soybean meal, 5 parts of corn, 12 parts of cottonseed meal, 6 parts of rapeseed meal 4 parts, 4 parts of moxa extract by-products, 3 parts of eucommia extract by-products, 4 parts of rosemary extract by-products;

[0031] The weight ratio of the basic raw material to water is 97:3, and the ratio o...

Embodiment 2

[0044] The difference from Example 1 is that, except for the amount of wheat bran, calcium hydrogen phosphate, salt and premix in a feed for eggs and poultry, the components and amounts of each raw material are as follows: 54 parts of corn, 13.8 parts of rice bran meal, fermented material 14.2 parts, 2 parts of conjugated linoleic acid glycerides, 1.2 parts of soybean lecithin powder, 8.6 parts of granular stone powder;

[0045] In the fermented material, except that the amount of rapeseed meal remains unchanged, 60 parts of soybean meal, 6 parts of corn, 11 parts of cottonseed meal, 3 parts of by-products extracted from moxa, 4 parts of by-products extracted from Eucommia, and 5 parts of by-products extracted from rosemary .

[0046] In the steps 1 and 3, the steam pressure is 0.30 MPa, the conditioning temperature is 85° C., and the conditioning time is 20 s.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com