Method for synthesizing cuprous oxide nano-cubes on large scale based on continuous kettle type device

A cuprous oxide, continuous kettle technology, applied in copper oxide/copper hydroxide and other directions, can solve problems such as low stability, low production efficiency, and difficulty in amplification, and achieve low labor costs, high production efficiency, and easy to scale up experiments. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

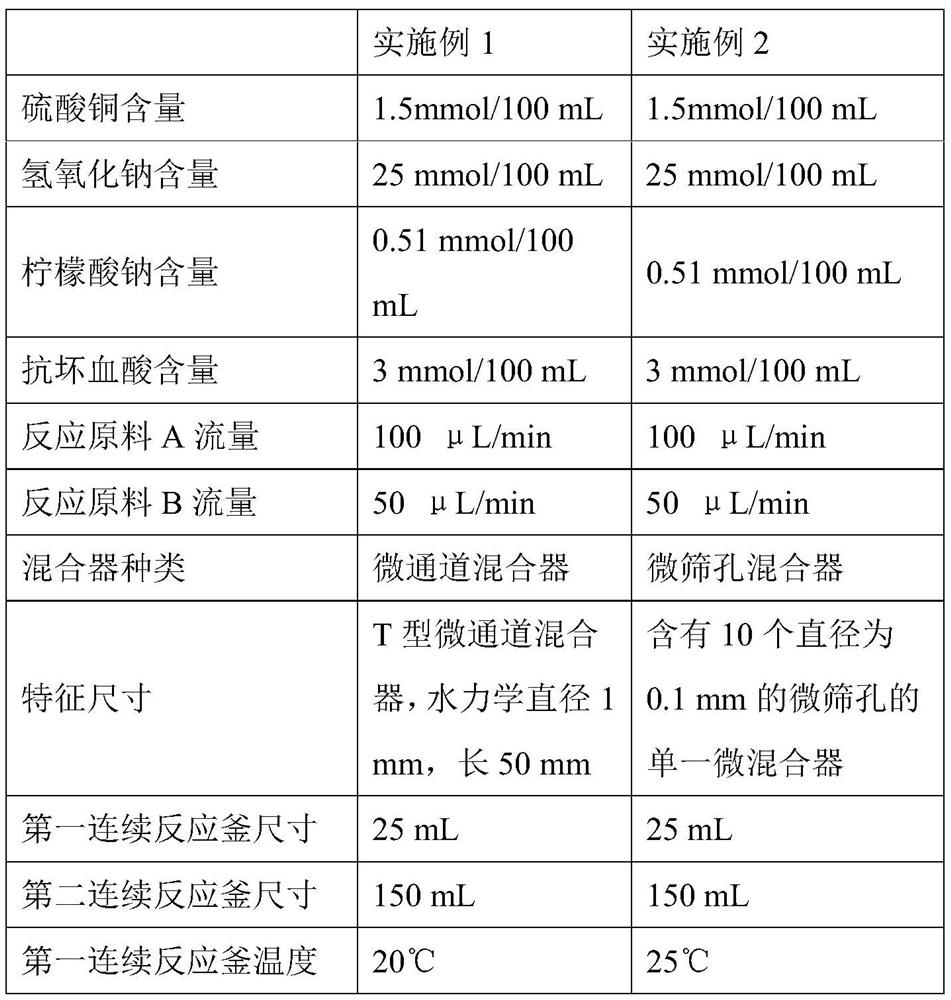

[0028] A method for mass-synthesizing cuprous oxide nano cubes based on a continuous kettle type device, comprising the following steps:

[0029] 1) Weigh copper sulfate, sodium citrate, sodium hydroxide and ascorbic acid, respectively add deionized water at room temperature and sonicate until the solution is clarified to obtain a mixed solution of copper sulfate, sodium citrate, sodium hydroxide and ascorbic acid solution.

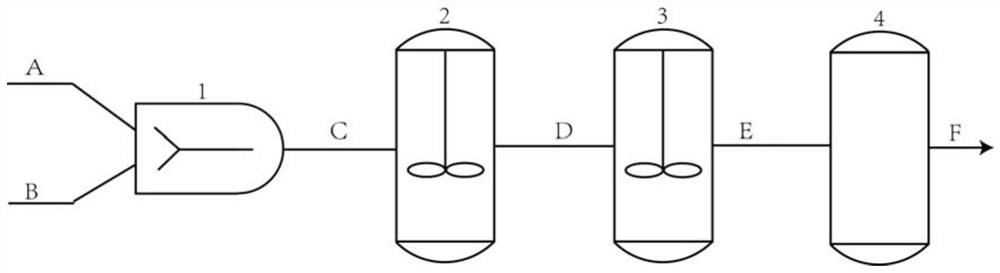

[0030] 2) According to figure 1 Build a continuous continuous reactor device, use a constant flow pump to transport the reaction raw materials obtained in step 1) to the continuous reactor reaction system for reaction, monitor the temperature of the continuous reactor in real time, and finally collect the product through the collection tank.

[0031] 3) The product solution is sequentially diluted with deionized water and absolute ethanol, washed, centrifuged, and dried to obtain cuprous oxide nanocubes, which are weighed to calculate the yield. The spec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com