Cement adhesive for large-tonnage glass insulator

A technology for glass insulators and cement adhesives, applied in the field of cement adhesives, can solve the problems of low fluidity, reduce water-binder ratio, etc., and achieve the effects of improving strength, increasing slurry compactness, and meeting the requirements of production glue packaging process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

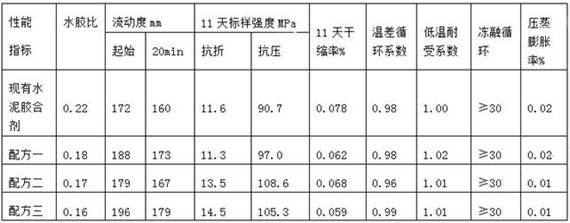

Examples

Embodiment 1

[0016] Example 1: A cement adhesive for large-tonnage glass insulators, which consists of the following components in weight percentages, including 51.5% cement, 28.6% glued sand, 2.06% silica fume, 0.015% anti-crack fiber, and 6.7% micropowder , plastic retaining agent 0.026%, water reducing agent 0.26%, water 10.8%.

[0017] In this embodiment, the cement is Portland cement.

[0018] In this embodiment, the gelatinized sand is river sand, and the mesh size of the river sand is 50 mesh.

[0019] In this embodiment, the silicon dioxide content in silica fume is 92%.

[0020] In this embodiment, the crack-resistant fibers are polypropylene fibers, and the fiber length of the polypropylene fibers is 5 mm.

[0021] In this embodiment, the micropowder is microbeads.

[0022] In this embodiment, the plastic retaining agent is sodium gluconate.

[0023] In this embodiment, the water reducer is a low-foam naphthalene-based water reducer powder.

Embodiment 2

[0024] Example 2: A cement adhesive for large-tonnage glass insulators, which consists of the following components in weight percentages, including 48.6% cement, 32.4% glued sand, 1.94% silica fume, 0.015% anti-crack fiber, and 6.81% micropowder , plastic retaining agent 0.015%, water reducing agent 0.34%, water 9.86%.

[0025] In this embodiment, the cement is Portland cement.

[0026] In this embodiment, the cemented sand is quartz sand, and the mesh number of the quartz sand is 60 mesh.

[0027] In this embodiment, the silicon dioxide content in silica fume is 95%.

[0028] In this embodiment, the crack-resistant fibers are polypropylene fibers, and the fiber length of the polypropylene fibers is 6 mm.

[0029] In this embodiment, the micropowder is composed of precipitated silica micropowder and microbeads, wherein the weight percent of microbeads is 6.32%, and the weight percent of precipitated silica micropowder is 0.49%.

[0030] In this embodiment, the plastic retai...

Embodiment 3

[0032] Example 3: A cement adhesive for large-tonnage glass insulators, which is composed of the following components in weight percentages, including 46.5% cement, 31.0% glued sand, 1.86% silica fume, 0.014% anti-crack fiber, and 10.69% micropowder , plastic retaining agent 0.014%, water reducing agent 0.32%, water 9.53%.

[0033] In this embodiment, the cement is Portland cement.

[0034] In this embodiment, the glued sand is river sand, and the mesh size of the river sand is 70 mesh.

[0035] In this embodiment, the silicon dioxide content in silica fume is 93%.

[0036] In this embodiment, the crack-resistant fibers are polypropylene fibers, and the fiber length of the polypropylene fibers is 6 mm.

[0037] In this embodiment, the micropowder is composed of slag micropowder and microbeads, wherein the weight percent of slag micropowder is 4.65%, and the weight percent of microbeads is 6.04%.

[0038] In this embodiment, the plastic retaining agent is sodium gluconate. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com