Method for predicting adsorption capacity of activated carbon to volatile organic compounds

A volatile organic compound and activated carbon adsorption technology, which is applied in the direction of chemical property prediction, separation methods, chemical instruments and methods, etc., can solve the problems of few influencing factors and low accuracy, and achieve simple operation, high accuracy and wide application range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

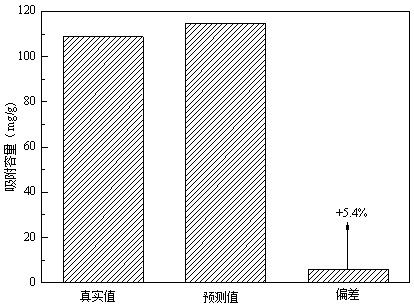

Embodiment 1

[0030] Predict the adsorption capacity of activated carbon for ethanol in a published literature; the specific surface area of activated carbon: 766m 2 / g, total pore volume: 0.41cm 3 / g, surface oxygen content: 8%; adsorption temperature: 30°C, ethanol concentration: 800ppm, relative humidity: 50%; ethanol molecular weight: 46g / mol, boiling point: 78°C, polarity: 1.69D.

[0031] Three groups of adsorption data of methanol, ethanol, and n-propanol on activated carbon were collected. The difference between predicted physical and chemical properties of activated carbon and adsorption conditions is ≤±5%. The selected methanol, ethanol, and n-propanol belong to the same category as the ethanol to be predicted. The specific values of the physical and chemical properties of methanol, ethanol, and n-propanol are shown in Table 1.

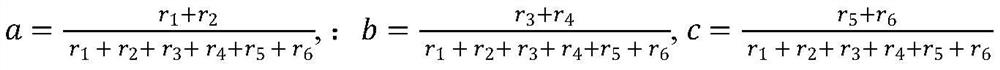

[0032] Taking the boiling point (°C), molecular weight (g / mol) and polarity (D) of VOCs as the abscissa and the adsorption amount (mg / g) as the ordina...

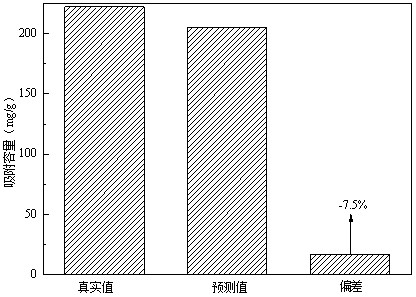

Embodiment 2

[0053] Predict the adsorption capacity of a kind of activated carbon for toluene in the laboratory; the specific surface area of activated carbon: 987.1m 2 / g, total pore volume: 0.47cm 3 / g, surface oxygen content: 7.3%; adsorption temperature: 40°C, toluene concentration: 500ppm, relative humidity: 80%; toluene molecular weight: 92g / mol, boiling point: 110.6°C.

[0054] The adsorption data of three groups of toluene, benzene, and p-xylene on activated carbon were collected. The difference between the predicted physical and chemical properties of activated carbon and adsorption conditions is ≤±5%. The selected toluene, benzene, and p-xylene belong to the same category as the toluene to be predicted. The specific values of the physical and chemical properties of toluene, benzene, and p-xylene are shown in Table 2.

[0055] Taking the boiling point (°C), molecular weight (g / mol) and polarity (D) of VOCs as the abscissa and the adsorption amount (mg / g) as the ordinate, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Total pore volume | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com