Preparation method of lithium-sulfur battery current collector

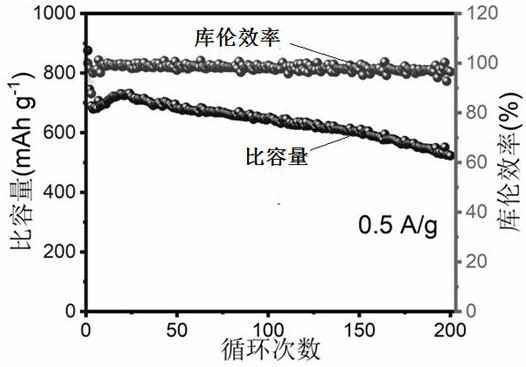

A lithium-sulfur battery and current collector technology, which is applied in the field of preparation of three-dimensional self-supporting lithium-sulfur battery current collectors, can solve the problems of low utilization rate of active materials, fast capacity decay, poor rate performance, etc., and achieve high reproducibility and high load capacity. The effect of high volume and long cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A preparation method of a lithium-sulfur battery current collector, the specific steps are as follows:

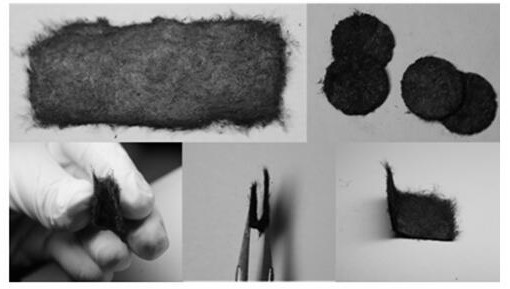

[0027] (1) Cleaned biomass cattails are evenly spread between two graphite sheets (30mm*50mm), the biomass mass is 650mg, and pre-carbonized in a muffle furnace at 240°C for 2h in an air atmosphere. The carbonized sample was carbonized at 850 °C for 2 h in an Ar atmosphere, and after cooling to 700 °C, CO 2 Activation under the atmosphere for 2h, to obtain a three-dimensional self-supporting carbon material with the same quality as the conventional current collector aluminum foil; as figure 1 Shown is the topography of the prepared three-dimensional self-supporting carbon material. It can be seen from the figure that the prepared material is a flexible three-dimensional self-supporting carbon material;

[0028] (2) Disperse nickel sulfide in ethanol / water (volume ratio 1:1) solvent according to the mass volume ratio g:mL of 1:5 to obtain a uniform slurry, and vulcan...

Embodiment 2

[0032] A preparation method of a lithium-sulfur battery current collector, the specific steps are as follows:

[0033] (1) The cleaned biomass bamboo fiber is evenly spread between two graphite sheets (30mm*50mm), and the biomass quality is 500mg. In the muffle furnace, under the air atmosphere, pre-carbonize at 100°C for 2h, the The pre-carbonized samples were carbonized at 500 °C for 3 h under Ar atmosphere, and then in CO 2 Activation at 500°C for 3 hours in the atmosphere to obtain a flexible three-dimensional self-supporting carbon material with the same quality as the conventional current collector aluminum foil;

[0034] (2) Disperse nano-titanium dioxide in ethanol / water (volume ratio 1:1) solvent in a ratio of 1:5 according to the mass volume ratio g:mL to obtain a uniform slurry, and obtain a uniform slurry according to the final material titanium dioxide 5% by mass is coated on the flexible three-dimensional self-supporting carbon material obtained in step (1) to o...

Embodiment 3

[0038] A preparation method of a lithium-sulfur battery current collector, the specific steps are as follows:

[0039] (1) Cleaned biomass cattail and bamboo fiber mass ratio 1:1 are evenly spread between two graphite sheets (30mm*50mm), the biomass mass is 750mg, in the muffle furnace, under the air atmosphere, with Pre-carbonize at 300°C for 1 h, carbonize the pre-carbonized sample at 900°C for 1 h in an Ar atmosphere, and then carbonize at 900°C in CO 2 Activated under the atmosphere for 1h to obtain a flexible three-dimensional self-supporting carbon material with the same quality as the conventional current collector aluminum foil;

[0040] (2) The commercial Mxene (Ti 3 C 2 ) is dispersed in ethanol / water (volume ratio 1:1) solvent to obtain uniform slurry according to the ratio of mass volume ratio g:mL being 1:5, and the homogeneous slurry obtained is coated with 20% of the mass content of the final material Mxene Coated on the flexible three-dimensional self-suppor...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap