Preparation method of mesoporous Beta molecular sieve

A molecular sieve and mesoporous technology, applied in the direction of molecular sieves and alkali exchange compounds, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of low product yield, high COD, high waste water discharge, etc., achieve excellent diffusion performance and reduce manufacturing costs. Effect of high cost and specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

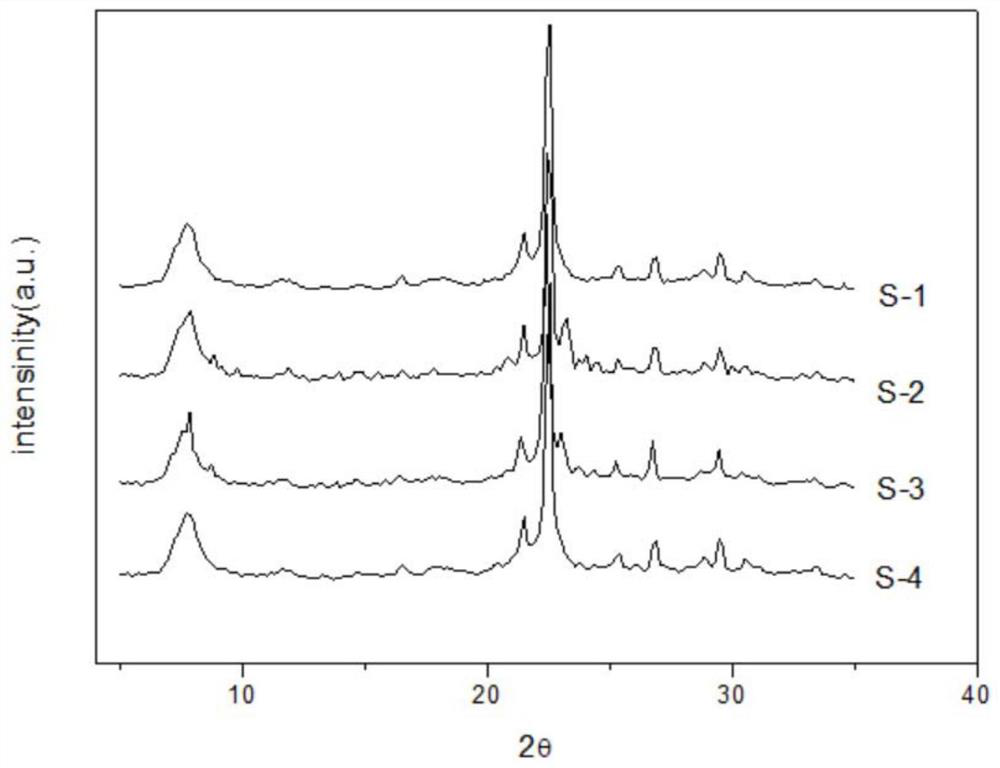

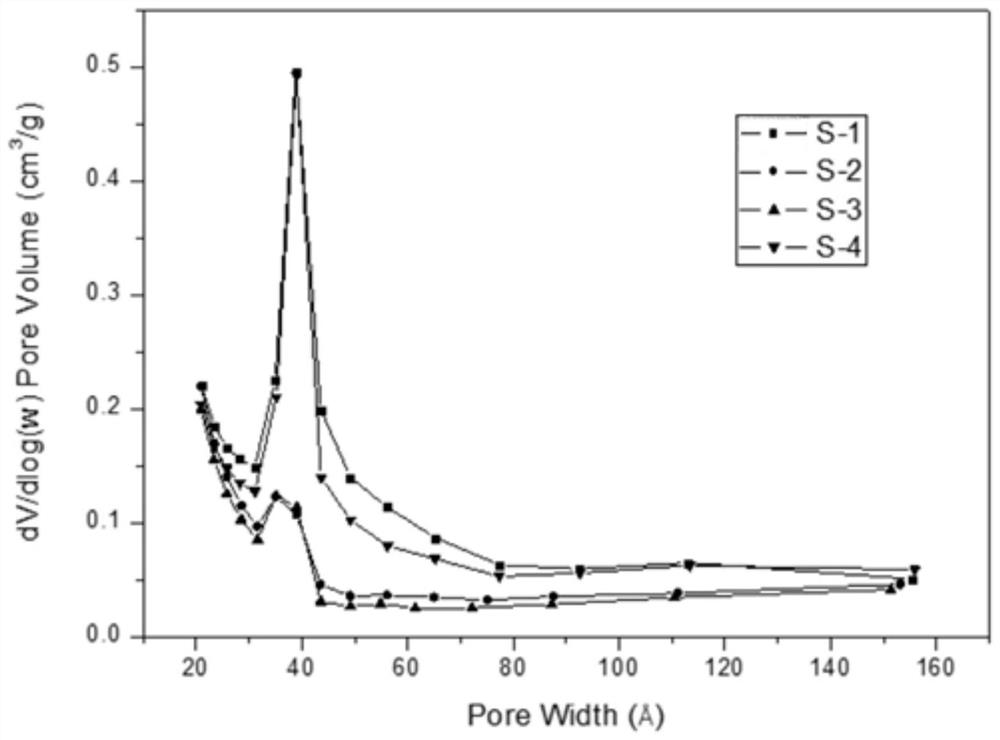

[0036] Examples 1-4 sequentially select the four directing agent solutions prepared above to prepare mesoporous Beta molecular sieves.

[0037] Mesoporous Beta molecular sieve synthesis: Mix Y-type molecular sieve and alkali source (sodium hydroxide) in deionized water evenly, then add directing agent solution, and continue to stir fully. After the gel was stirred evenly, it was transferred to a reaction kettle for crystallization. After the crystallization is completed, the product is removed from the mother liquor, washed with water, exchanged, dried, and roasted to obtain the sample of the embodiment: denoted as: S-1-4. The details are shown in Table 3.

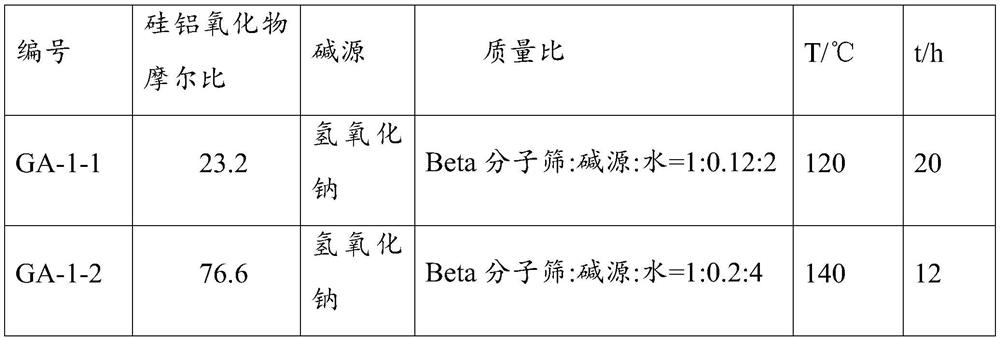

[0038] Table 3: Raw material proportions and crystallization conditions involved in Examples 1-4.

[0039]

[0040]

[0041] Table 4: Examples 1-4 samples and comparative sample physical parameters

[0042] Numbering relative crystallinity Specific surface area (m 2 / g)

Pore volume (cm 3 / g)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com