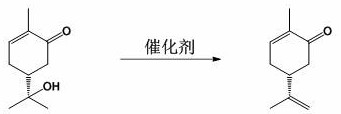

Method for synthesizing chiral carvone from chiral 8-hydroxycarvone

A technology of hydroxycarvone and carvone, applied in the chemical field, can solve problems such as unfavorable industrialized production, complicated reaction route, expensive gold catalyst, etc., and achieve the effects of good industrial application prospect, high reaction efficiency, and reduced production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Add 500g of L-8-hydroxycarvone, 100g of mesitylene and 100g of catalyst (copper supported on carbon media material, copper content is 3wt%) into a 1000 mL reactor, then react at 160~170℃ for about 6~ After 7 hours, GC showed that after the reaction was over, the catalyst was removed by filtration, and the filtrate was rectified under reduced pressure to reclaim 98 g of the catalyst and 96 g of mesitylene as a solvent. %. The catalyst obtained by filtration can be reused.

Embodiment 2

[0024] Add 500g of L-8-hydroxycarvone, 60g of diphenyl ether and 98g of the catalyst recovered in Example 1 into a 1000 mL reactor, then react at 210-230°C for about 2-3 hours, after GC shows that the reaction is over, filter The catalyst was removed, the filtrate was rectified under reduced pressure, and 96g of the catalyst was recovered, and further rectified to obtain 427g of L-carvone finished product with a content greater than 97%, with a yield of 96%. The catalyst obtained by filtration can be reused.

Embodiment 3

[0026] Add 500g of L-8-hydroxycarvone, 150g of N-methylpyrrolidone and 96g of the catalyst recovered in Example 2 into a 1000 mL reactor, then react at 190 to 200°C for about 5 to 6 hours, and GC shows that after the reaction ends, The catalyst was removed by filtration, and the filtrate was rectified under reduced pressure to recover 92 g of the catalyst, and further rectified to obtain 421 g of L-carvone finished product with a content greater than 97%, with a yield of 94%. The catalyst obtained by filtration can be reused.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com