A kind of preparation method of polymer polyester antistatic agent

An antistatic agent and polymer technology, applied in the field of preparation of polymer polyester antistatic agent, can solve the problems of discount of antistatic effect and easy migration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

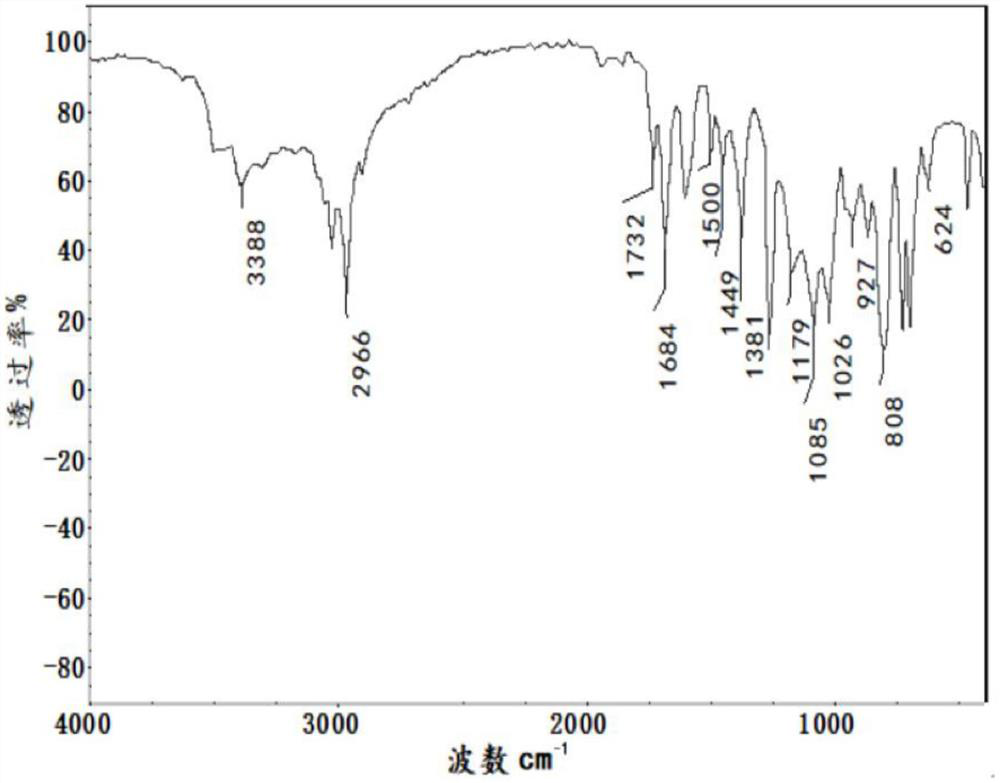

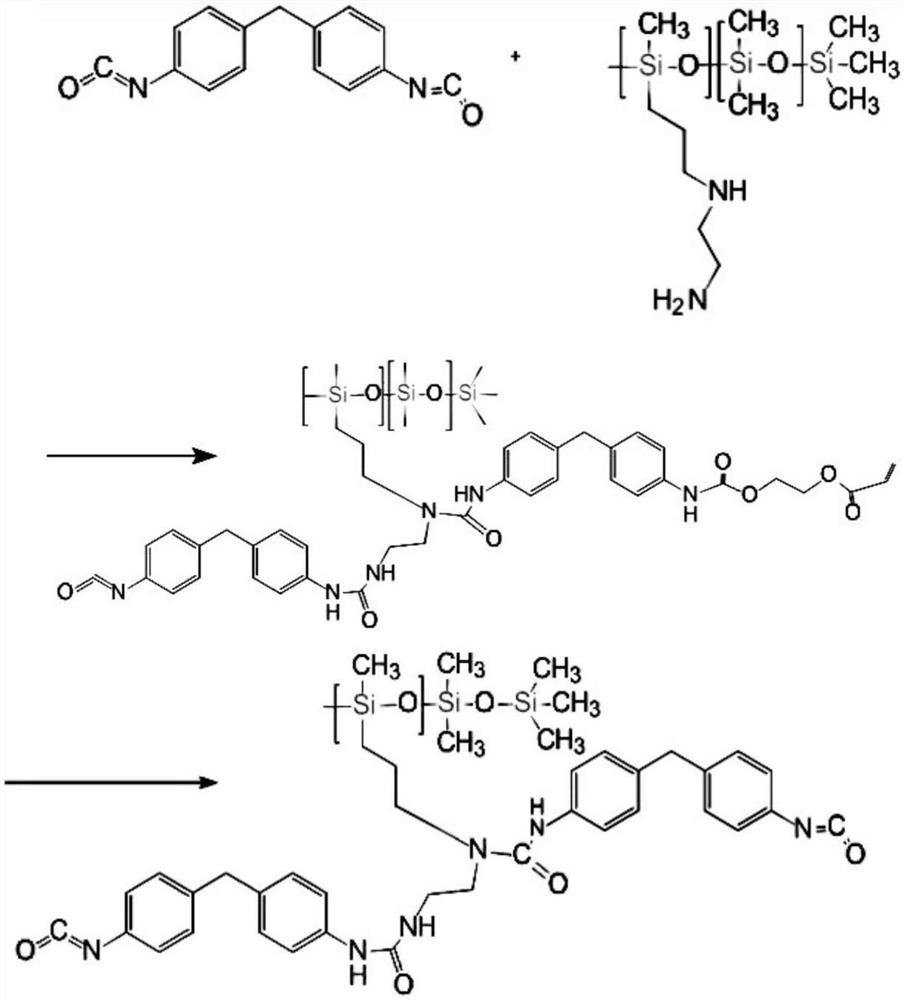

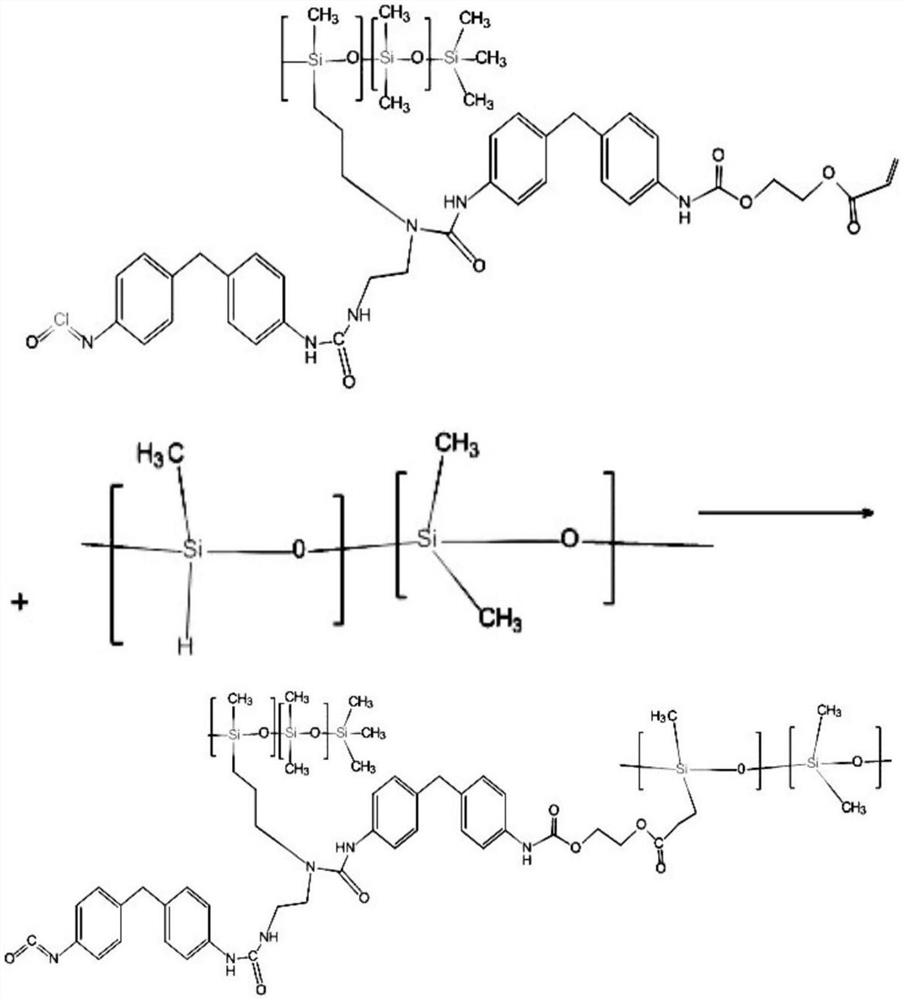

Image

Examples

Embodiment 1

[0032] A kind of preparation method of polymer polyester antistatic agent, its specific scheme is as follows:

[0033] Add 29.2g of adipic acid and 8.1g of metal oxides into 80g of acetone, control the temperature at 30°C, and react under reflux for 40min. After completion, filter, wash and dry to obtain a salt-containing dibasic acid; mix the obtained salt-containing dibasic acid with Mix 220g of polyether diol modified with sulfonic acid groups evenly, add 0.5g of catalyst, raise the temperature to 130°C under the protection of nitrogen, and react at constant temperature for 4 hours. After completion, add 18.2g of phenyl-containing polyisocyanate and 0.2g of antioxidant , stir and mix evenly, control the temperature to 150°C, react for 120min, then react under reduced pressure for 30min, discharge the material after the reaction, cool to room temperature, crush the material, wash in a water bath at 60°C for 30min, filter, and dry to obtain Described a kind of polymer polyest...

Embodiment 2

[0046] A kind of preparation method of polymer polyester antistatic agent, its specific scheme is as follows:

[0047] Add 36.4g of adipic acid and 10.2g of metal oxides into 100g of acetone, control the temperature at 35°C, and conduct a reflux reaction for 80 minutes. After completion, filter, wash and dry to obtain a salt-containing dibasic acid; combine the obtained salt-containing dibasic acid with Mix 1000g of polyether diol modified with sulfonic acid groups evenly, add 1.2g of catalyst, raise the temperature to 140°C under the protection of nitrogen, and react at constant temperature for 6h. After completion, add 20.4g of phenyl-containing polyisocyanate and 0.4g of antioxidant , stir and mix evenly, control the temperature to 160°C, react for 150min, then react under reduced pressure for 40min, discharge the material after the reaction, cool to room temperature, crush the material, wash in a water bath at 70°C for 40min, filter, and dry to obtain Described a kind of p...

Embodiment 3

[0060] A kind of preparation method of polymer polyester antistatic agent, its specific scheme is as follows:

[0061] Add 43.8g of adipic acid and 12.3g of metal oxides into 120g of acetone, control the temperature at 45°C, and react under reflux for 120min. After completion, filter, wash and dry to obtain a salt-containing dibasic acid; combine the obtained salt-containing dibasic acid with Mix 2000g of polyether diol modified with sulfonic acid groups evenly, add 1.6g of catalyst, raise the temperature to 160°C under the protection of nitrogen, and react at constant temperature for 8 hours. After completion, add 22.8g of phenyl-containing polyisocyanate and 0.6g of antioxidant , stir and mix evenly, control the temperature to 180°C, react for 180min, then react under reduced pressure for 60min, discharge the material after the reaction, cool to room temperature, pulverize the material, wash in a water bath at 80°C for 60min, filter, and dry to obtain Described a kind of pol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com