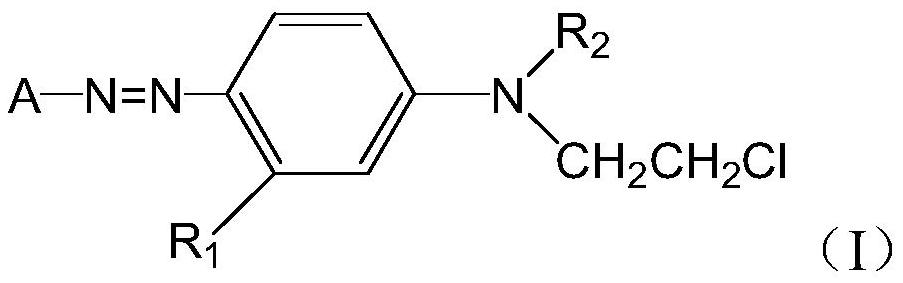

Azo-type disperse dye compound suitable for dyeing in acid-alkaline bath, its preparation method, composition and application

A technology of disperse dyes and compounds, applied in azo dyes, monoazo dyes, dyeing methods, etc., to achieve excellent perspiration fastness, improved dyeing performance, and good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

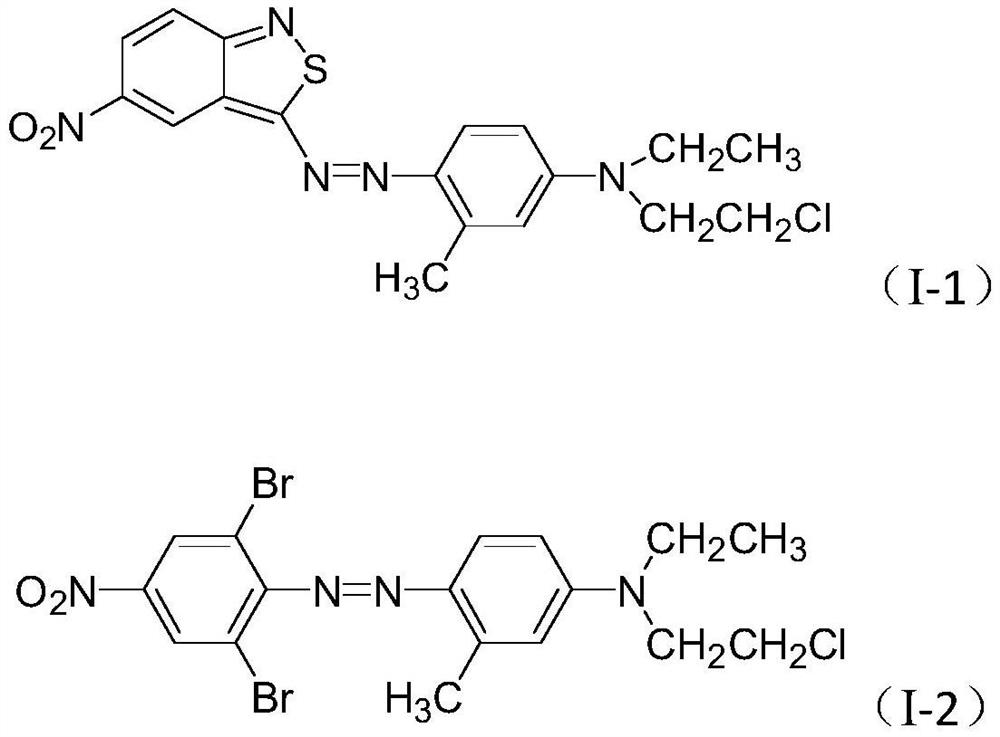

Embodiment 1

[0031] 250mL flask add 180g sulfuric acid (98%), 40g phosphate (85%), 96g nitrosyl sulfate (28%), 40g below 5 °C 3-amino-5-nitro-2,1-benzisothiazole (0.205mol), 0 ~ 5 °C insulation reaction for 4 hours, to obtain diazo liquid, to be used;

[0032] Add 250g of ice water, 20g of 98 acid, 2g of TX-10-2, 43g of N-ethyl-N-chloroethyl m-toluidine (0.205mol), 1g of aminosulfonic acid, fully dissolved pulp, add crushed ice to cool below 0 °C, and then slowly add nitrogen to the coupling component at 0 ~5 °C, stir until the coupling reaction is over, continue to stir for 2h, slowly heat up to 60 °C, keep warm for 2 hours, filter, wash to neutral, dry. The dye compound (I-1) was prepared, the filter cake was dried 73.3g, the yield was 88.5%, and the HPLC: 97.34%.

Embodiment 2

[0034] 250mL flask add 30g of sulfuric acid, 39g of nitrosyl sulfate, stir, cool down to 20 °C, start slowly adding 25g2,6-dibromo-4-nitroaniline, cast at 30 ~ 35 °C for 2h, set aside.

[0035] Add 200g of ice water to 1000mL beaker, turn on stirring, slowly add 20g98 acid, 1g of sulfamic acid, 1gTX-10-2, 13.5g of N-ethyl-N-chloroethyl m-toluidine with a content of 99%, beat the pulp to fully dissolve, and then add crushed ice to cool down to below 0 °C, and then slowly add nitrogen to the coupling component at 0 ~5 °C, stir until the coupling reaction is over, continue to stir for 2h, slowly heat up to 90 °C, heat up to crystallization for 2 hours, filter, wash to neutral, and prepare the dye monomer (I-2), filter cake dry 32.35g, yield 94.92%, HPLC: 98.86%.

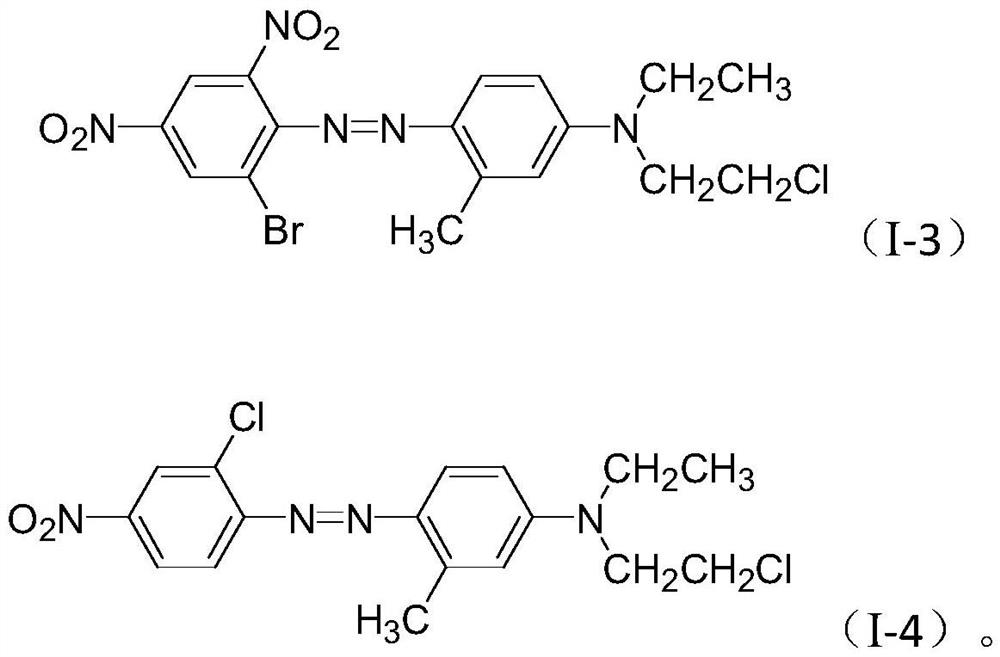

Embodiment 3

[0037] 250mL flask added 21g of sulfuric acid, 43.8g of nitrite sulfate, stirred, cooled to 20 °C, began to slowly add 2,4-dinitro-6-bromoaniline 25g, cast at 25 ~ 30 °C for 2h, set aside.

[0038]2000mL beaker add 500g of ice water, 20g of 98% acid, 1.5gTX-10-2, 19g of 99% N-ethyl-N-chloroethyl m-toluidine, 1g of sulfamic acid, beat fully dissolved, and then add crushed ice to cool down to below 0 °C, and then slowly drop nitrogen into the coupling component at -5 ~5 °C, stir until the coupling reaction is over, continue to stir for 2h, slowly heat up to 60 °C, keep warm for 2 hours, filter, wash to neutral, to obtain dye monomer (I-3), The filter cake dried 40.85g, yield 90.99%, HPLC: 94.76%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com