Adhesive sheet, backlight unit, and display device

A technology of adhesive sheet and backlight source, applied in the direction of optical components, optics, adhesives, etc., can solve the problems of uneven image brightness and low water resistance of illuminants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0099] (2) Preparation of adhesive composition P

[0100] The adhesive composition P can be prepared by the preparation of (meth) acrylate polymer (a), the resulting (meth) acrylate polymer (A), a crosslinking agent (B) and optical diffusion Particles (C) mixed while adding additives to the desired addition.

[0101] (Meth) Acrylate Polymer (a) can be prepared by polymerizing a mixture of monomers constituting the polymer using a usual free radical polymerization. The polymerization of the (meth) acrylate polymer (A) is preferably carried out as needed using a polymerization initiator and is carried out by solution polymerization. However, the present invention is not limited thereto, or polymerization can be carried out without solvent. Examples of the polymerization solvent include ethyl acetate, n-butyl acetate, isobutyl acetate, toluene, acetone, hexane, methyl ethyl ketone, or the like, can also be used simultaneously.

[0102] Examples of the polymerization initiator include...

manufacture example

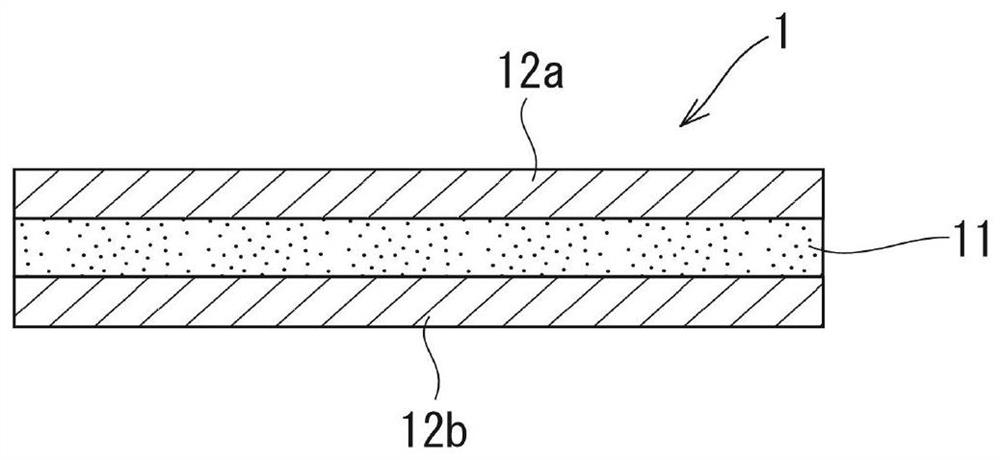

[0128] As a manufacturing example of the adhesive sheet 1, the case where the above adhesive composition P is used. The coating liquid of the adhesive composition P is applied to the release surface of a peeling piece 12a (or 12b), and the heating treatment is performed to heat the adhesive composition P, and after the coating layer is formed, the coating layer is formed. The stripping surface of another peeling piece 12b (or 12a) is superimposed. When the ripening period is required, by setting the ripening period, the coating layer is a adhesive layer 11, and the coating layer is directly formed in the adhesive layer 11 when the coating stage is required. Thereby, the adhesive sheet 1 is obtained. Conditions of heating treatment and ripening are as described above.

[0129] As another manufacturing example of the adhesive sheet 1, the coating liquid coated with the adhesive composition P is applied to the peel surface of a peeling piece 12a, and the adhesive composition P is comb...

Embodiment 1

[0173] 1. Preparation of (meth) acrylate polymer

[0174] 3 parts by mass of acrylate, 30 parts by mass of acrylate, 10 parts by mass of acrylate, 10 parts by mass of acrylate, 10 parts by mass of acryl morpholine and 20 parts by mass of acrylate, prepared (Meth) acrylate polymer (a). The molecular weight of the (meth) acrylate polymer (A) was measured by the method described later, and as a result, the weight average molecular weight (MW) was 500,000.

[0175] 2. Preparation of the adhesive composition

[0176] 100 parts by mass (solid component conversion value; the same), the following step 1 (meth) acrylate polymer (A), 0.2 parts by mass of trihydroxymethyl propylene alkane as a crosslinking agent (B) Polybenzoisoco., LTD. Made, product name "BHS8515"), 7.5 parts by weight of the silicone resin (containing a silicon-containing compound having an inorganic and organic intermediate structure) is formed by light diffusion particles (C). Light diffusion particles (C1; Momentive Pe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adhesion | aaaaa | aaaaa |

| Adhesion | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com