Sludge treatment method

A sludge treatment and sludge technology, applied in sludge treatment, biological sludge treatment, water/sludge/sewage treatment, etc., can solve the problem of insufficient utilization of sludge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

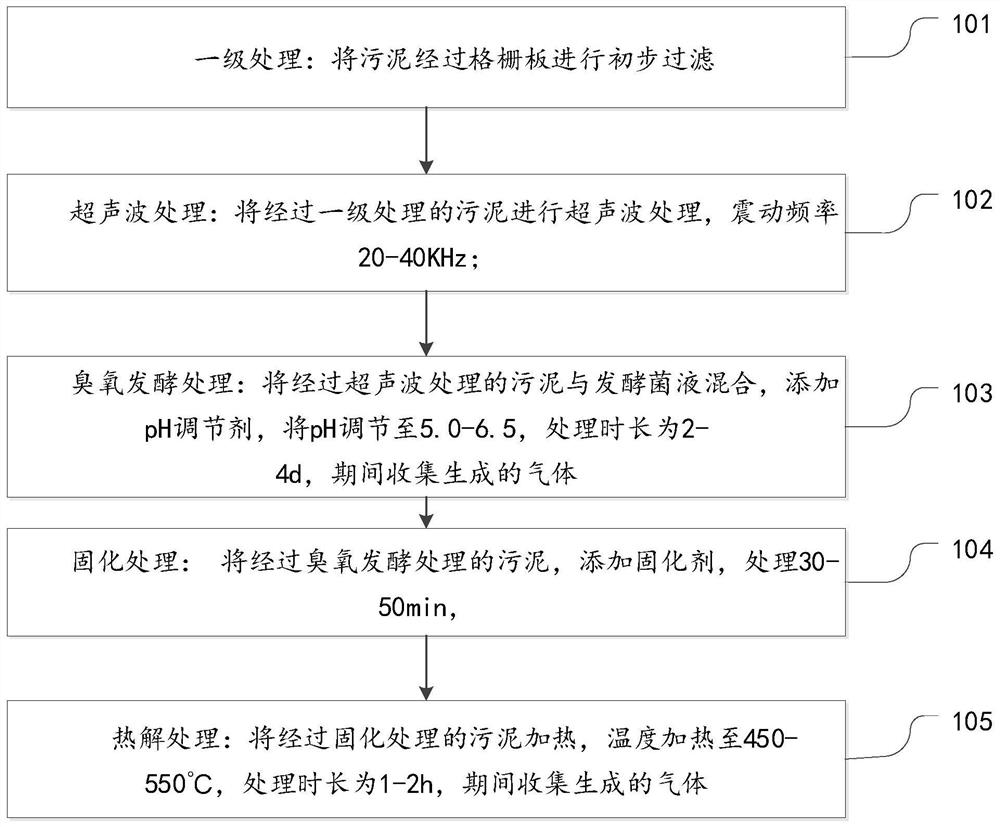

[0033] A sludge treatment method is characterized in that comprising the steps of:

[0034] Primary treatment: pass the sludge through the grid plate for preliminary filtration;

[0035] Ultrasonic treatment: Ultrasonic treatment is performed on the sludge that has undergone primary treatment, and the vibration frequency is 40KHz;

[0036] Ozone fermentation treatment: mix the ultrasonically treated sludge with the fermentation liquid, add a pH regulator, adjust the pH to 5.0-6.5, and the treatment time is 2-4 days, during which the generated gas is collected;

[0037] Solidification treatment: add solidification agent to the sludge treated by ozone fermentation, and treat it for 30-50 minutes.

[0038] Pyrolysis treatment: heat the solidified sludge to 450-550°C, and the treatment time is 1-2h, during which the generated gas is collected.

[0039] The pH regulator includes acetic acid and sodium bicarbonate, the fermentation broth includes Bacillus pumilus, Enterobacter cloac...

Embodiment 2

[0041] A sludge treatment method is characterized in that comprising the steps of:

[0042] Primary treatment: pass the sludge through the grid plate for preliminary filtration;

[0043] Ultrasonic treatment: Ultrasonic treatment is performed on the sludge that has undergone primary treatment, and the vibration frequency is 20KHz;

[0044] Ozone fermentation treatment: mix the ultrasonically treated sludge with the fermentation liquid, add a pH regulator, adjust the pH to 5.0-6.5, and the treatment time is 2-4 days, during which the generated gas is collected;

[0045] Solidification treatment: add solidification agent to the sludge treated by ozone fermentation, and treat it for 30-50 minutes.

[0046] Pyrolysis treatment: heat the solidified sludge to 450-550°C, and the treatment time is 1-2h, during which the generated gas is collected.

[0047] The pH regulator includes acetic acid and sodium bicarbonate, the fermentation bacteria liquid includes denitrifying bacteria, p...

Embodiment 3

[0049] A sludge treatment method is characterized in that comprising the steps of:

[0050] Primary treatment: pass the sludge through the grid plate for preliminary filtration;

[0051] Ultrasonic treatment: Ultrasonic treatment is performed on the sludge that has undergone primary treatment, and the vibration frequency is 60z;

[0052] Ozone fermentation treatment: mix the ultrasonically treated sludge with the fermentation liquid, add a pH regulator, adjust the pH to 5.0-6.5, and the treatment time is 2-4 days, during which the generated gas is collected;

[0053] Solidification treatment: add solidification agent to the sludge treated by ozone fermentation, and treat it for 30-50 minutes.

[0054] Pyrolysis treatment: heat the solidified sludge to 450-550°C, and the treatment time is 1-2h, during which the generated gas is collected.

[0055] The pH regulator includes acetic acid and sodium bicarbonate, the fermented bacteria liquid includes Bacillus pumilus, Enterobacte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com