Preparation method of mercaptoacetic acid-2-ethylhexyl in molten salt hydrate

A technology of thioglycolic acid and ethylhexyl, which is applied in the field of preparation of thioglycolic acid-2-ethylhexyl, can solve the problem of restricting the output of thioglycolic acid-2-ethylhexyl, large amount of extractant, complicated technological process, etc. problems, to achieve the effect of simplifying the production process, simplifying separation, and reducing side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

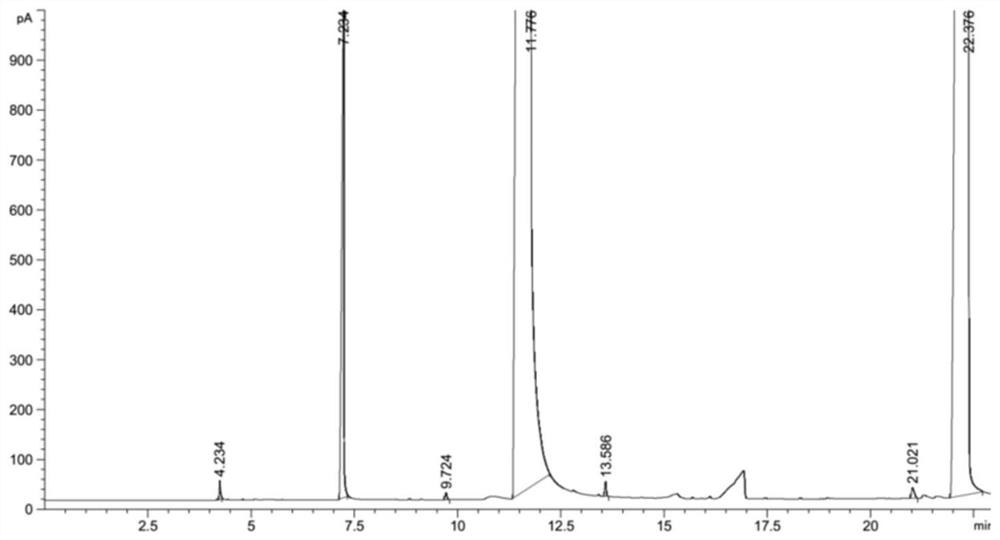

Image

Examples

Embodiment 1

[0043] (1) 1000 mL of thioglycolic acid acidified solution was added to the distillation flask in stages, dehydrated and concentrated by vacuum distillation, and NaCl solid was centrifuged to obtain 200 g of distilled concentrated solution; the concentration of thioglycolic acid was 49.0 wt.%.

[0044] (2) Slowly add CaCl to the distilled concentrate 2 100g, the NaCl of solid will be continuously separated out, after the NaCl solid separated out, merge with the NaCl solid of the centrifugation of step (1) gained to form solid salt; Then adopt the water washing solid salt that step (1) steams 2 times, The washed water is returned to step (1), and the washed solid salt is dried and used as a by-product.

[0045] CaCl added to distilled concentrate 2 The molten salt hydrate is formed with the water in the distilled concentrate to obtain a distilled concentrate containing the molten salt hydrate.

[0046] (3) To the distilled concentrated solution containing molten salt hydrate...

Embodiment 2

[0052] (1) 800 mL of thioglycolic acid acidified solution was added to the distillation flask in stages, decompressed and dehydrated and concentrated, and the NaCl solid was centrifuged to obtain 150 g of distilled concentrated solution; the concentration of thioglycolic acid was 55 wt.%.

[0053] (2) the distilled concentrated solution of step (1) is slowly added in the lower layer aqueous phase concentrated solution of embodiment 1, the NaCl of solid will be continuously separated out, after the NaCl solid separated out, with the centrifugal separation of step (1) gained The NaCl solids are combined to form a solid salt; then the solid salt is washed twice with the water distilled from the step (1), the washed water is returned to the step (1), and the washed solid salt is dried and used as a by-product.

[0054] At the same time, add a small amount of CaCl 2 , such that CaCl 2 The concentration is 60wt.%, CaCl 2 The concentration is calculated based on the quality of the ...

Embodiment 3

[0061] (1) 800 mL of thioglycolic acid acidified solution was added to the distillation flask in stages, decompressed and dehydrated and concentrated, and the NaCl solid was centrifuged to obtain 150 g of distilled concentrated solution; the concentration of thioglycolic acid was 60 wt.%.

[0062] (2) the distilled concentrated solution of step (1) is slowly added in the lower layer aqueous phase concentrated solution of embodiment 2, the NaCl of solid will be continuously separated out, after the NaCl solid separated out, with the centrifugal separation of step (1) gained The NaCl solids are combined to form a solid salt; then the solid salt is washed twice with the water distilled from the step (1), the washed water is returned to the step (1), and the washed solid salt is dried and used as a by-product. At the same time, add a small amount of CaCl 2 , such that CaCl 2 The concentration is 60wt.%, CaCl 2 The concentration is calculated based on the quality of the distilled...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com