High-transparency low-expansion polyimide film and preparation method thereof

A polyimide film and low-expansion technology, applied in the field of high-transparency and low-expansion polyimide film and its preparation, to achieve the effects of reducing thermal expansion coefficient, improving light transmittance, and low-expansion thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

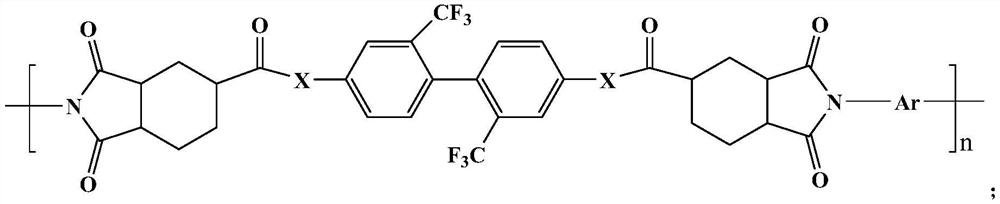

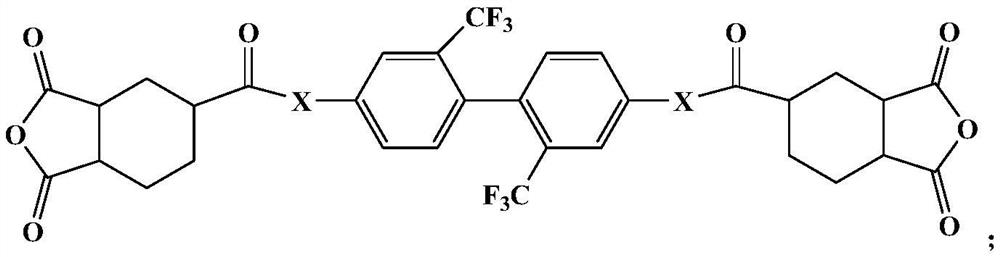

[0038] Prepare high transparency and low expansion polyimide film according to the following method:

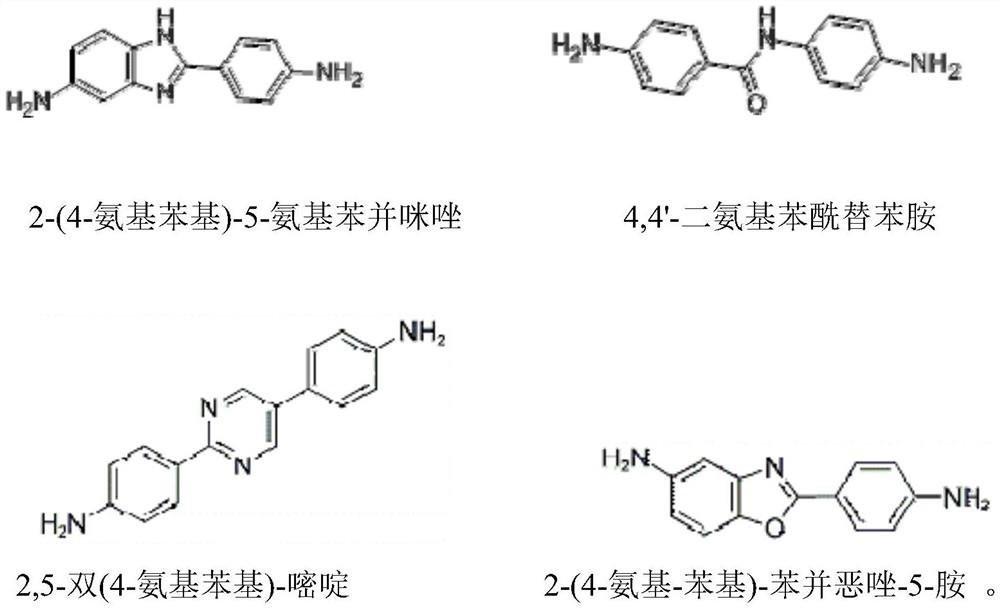

[0039] (1) Add 1.126g 2-(4-amino-phenyl)-benzoxazol-5-amine diamine monomer into a four-necked flask containing 18.252gDMAc, under nitrogen protection, stir to dissolve it; weigh Take 3.437g HTA-TFMB dianhydride monomer and add it to the above solution in batches under stirring condition, stir at 40°C for 4h, and obtain polyamic acid solution through polycondensation reaction;

[0040] (2) Add catalyst triethylamine 1.518g and dehydrating agent acetic anhydride 1.531g to the above polyamic acid solution for chemical imidization, stir at 40°C for 8h to obtain a polyimide solution;

[0041] (3) The obtained polyimide solution was cast on ultra-flat glass, and then dried in an oven at 100° C. for 24 hours to obtain a highly transparent and low-expansion polyimide film.

[0042] The performance of the obtained polyimide composite film was characterized, and the light transmittan...

Embodiment 2

[0044] Prepare high transparency and low expansion polyimide film according to the following method:

[0045] (1) Add 1.121g of 2-(4-aminophenyl)-5-aminobenzimidazolediamine monomer to a four-necked flask containing 18.232g of DMAc, and stir to dissolve it under nitrogen protection; weigh 3.437g HTA-TFMB dianhydride monomer was added to the above solution in batches under stirring conditions, stirred at 40°C for 4 hours, and polyamic acid solution was obtained through polycondensation reaction;

[0046] (2) Add catalyst triethylamine 1.518g and dehydrating agent acetic anhydride 1.531g to the above polyamic acid solution for chemical imidization, stir at 40°C for 8h to obtain a polyimide solution;

[0047] (3) The obtained polyimide solution was cast on ultra-flat glass, and then dried in an oven at 100° C. for 24 hours to obtain a highly transparent and low-expansion polyimide film.

[0048] The performance of the obtained polyimide composite film was characterized. The ligh...

Embodiment 3

[0050] Prepare high transparency and low expansion polyimide film according to the following method:

[0051] (1) Add 1.311g of 2,5-bis(4-aminophenyl)-pyrimidinediamine monomer into a four-necked flask containing 18.992g of DMAc, and stir to dissolve it under nitrogen protection; weigh 3.437g of HTA - TFMB dianhydride monomer is added to the above solution in batches under stirring conditions, stirred at 40°C for 4 hours, and polyamic acid solution is obtained through polycondensation reaction;

[0052] (2) Add catalyst triethylamine 1.518g and dehydrating agent acetic anhydride 1.531g to the above polyamic acid solution for chemical imidization, stir at 40°C for 8h to obtain a polyimide solution;

[0053] (3) The obtained polyimide solution was cast on ultra-flat glass, and then dried in an oven at 100° C. for 24 hours to obtain a highly transparent and low-expansion polyimide film.

[0054] The performance of the obtained polyimide composite film was characterized, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com