High-transparency PC product and preparation method thereof

A transparent and finished product technology, which is applied in the field of highly transparent PC products and its preparation, can solve the problems of high transparency and high-strength scratch resistance, etc., and achieve the effect of good surface gloss, stable quality and mild process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

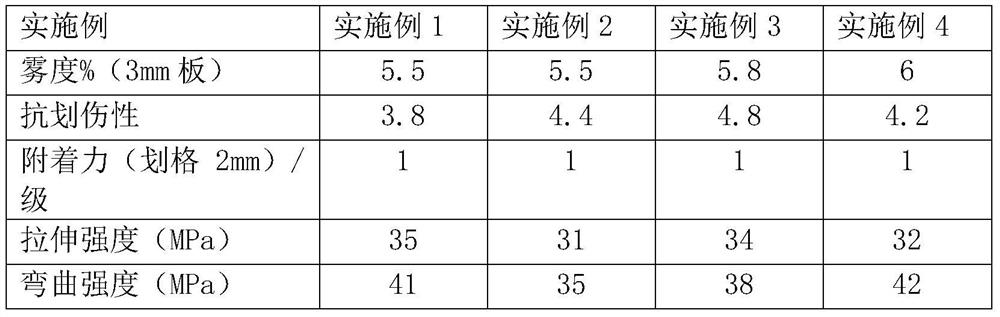

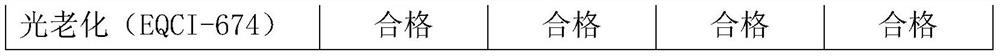

Examples

Embodiment 1

[0031] In Example 1, the resin base material is composed of PC resin, PMMA resin and ABS resin according to 8:2:1; the antioxidant is a hindered phenolic antioxidant; the anti-UV auxiliary agent is a benzophenone UV stabilizer; The transparent toughening agent is methyl methacrylate-butadiene-styrene copolymer; the compatibilizer is a mixture of ethylene-methyl acrylate copolymer EMA and styrene-maleic anhydride copolymer SMA.

Embodiment 2

[0032] In Example 2, the resin base material is composed of PC resin, PMMA resin and ABS resin according to 8:2:1; the antioxidant is a phosphite antioxidant; the anti-UV auxiliary agent is a benzotriazole UV stabilizer ; The transparent toughening agent is methyl methacrylate-butadiene-styrene copolymer; the compatibilizer is styrene-maleic anhydride copolymer SMA.

Embodiment 3

[0033] In embodiment 3, resin base material is made up of PC resin, PMMA resin and ABS resin according to 8:2:1; Antioxidant is hindered phenolic antioxidant and phosphite antioxidant mixed; Anti-UV auxiliary agent is A mixture of benzophenone UV stabilizers and triazine UV stabilizers; the transparent toughening agent is methyl methacrylate-butadiene-styrene copolymer; the compatibilizer is ethylene-methyl acrylate-methacrylate Glycidyl acrylate random terpolymer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com