Ultra-thin solar cell chip with omni-directional reflector and preparation method of ultra-thin solar cell chip

A corner mirror, solar cell technology, applied in the field of solar photovoltaic power generation, can solve problems such as unfavorable chip stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] The present invention will be further described below in conjunction with specific examples.

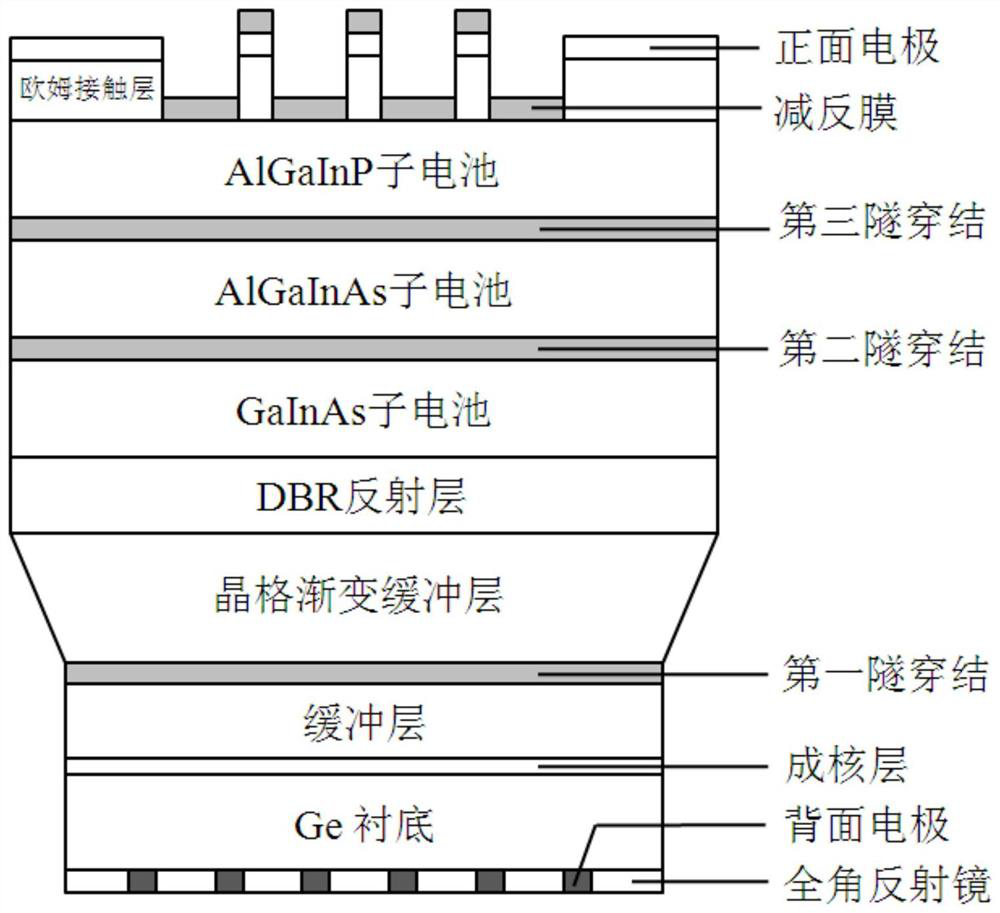

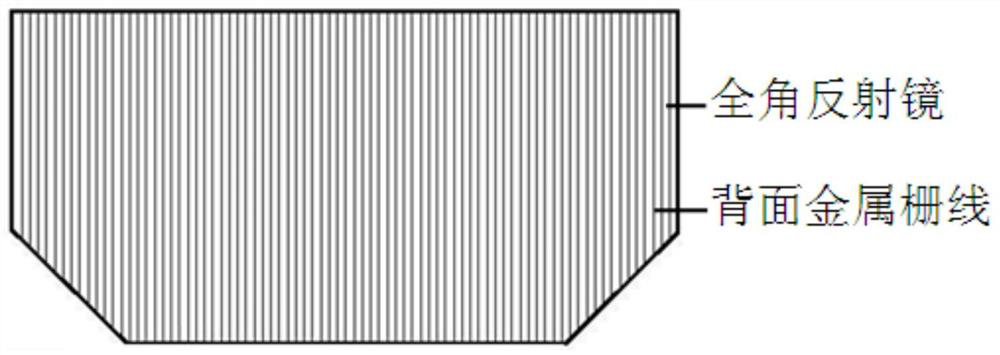

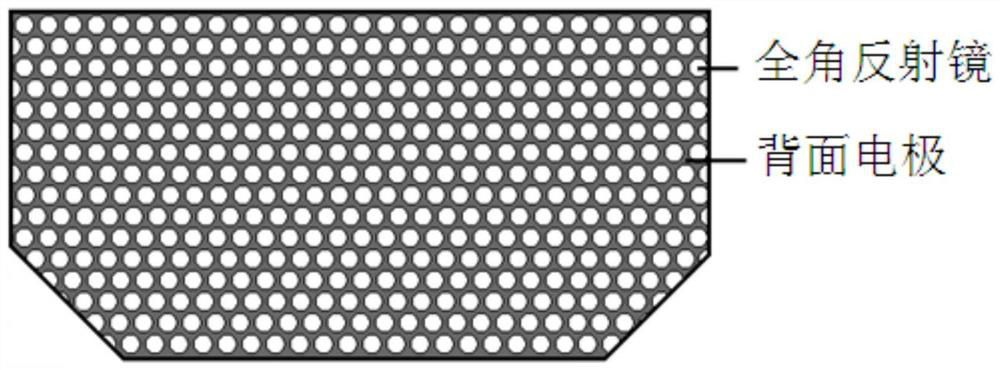

[0069] like figure 1 As shown, the present embodiment provides a kind of ultra-thin lattice-mismatched four-junction solar cell chip with omnidirectional reflector (ODR). An epitaxial layer is deposited on the upper surface of the bottom, and the epitaxial layer is arranged sequentially from bottom to top according to a layered superposition structure: Ga 0.5 In 0.5 P nucleation layer, GaIn 0.01 As buffer layer, first tunnel junction, GaInAs lattice graded buffer layer, AlGaInAs / GaInAs DBR reflective layer, GaInAs subcell, second tunnel junction, AlGaInAs subcell, third tunnel junction, AlGaInP subcell and GaInAs ohmic The contact layer, so far the preparation of the epitaxial wafer is completed; the anti-reflection film ARC and the front electrode are prepared on the front of the epitaxial wafer, the front of the epitaxial wafer is uniformly protected, the epitaxial wafer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com