Earth pressure balance shield foam system, working method and calculation method

An earth pressure balance shield and foam technology, which is applied in the fields of mixing methods, earthwork drilling, chemical instruments and methods, etc., can solve the problems of earth pressure balance shield tunneling spurts, different calculation methods, and large gas volume, etc. Novel method, clear control logic and reasonable working process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

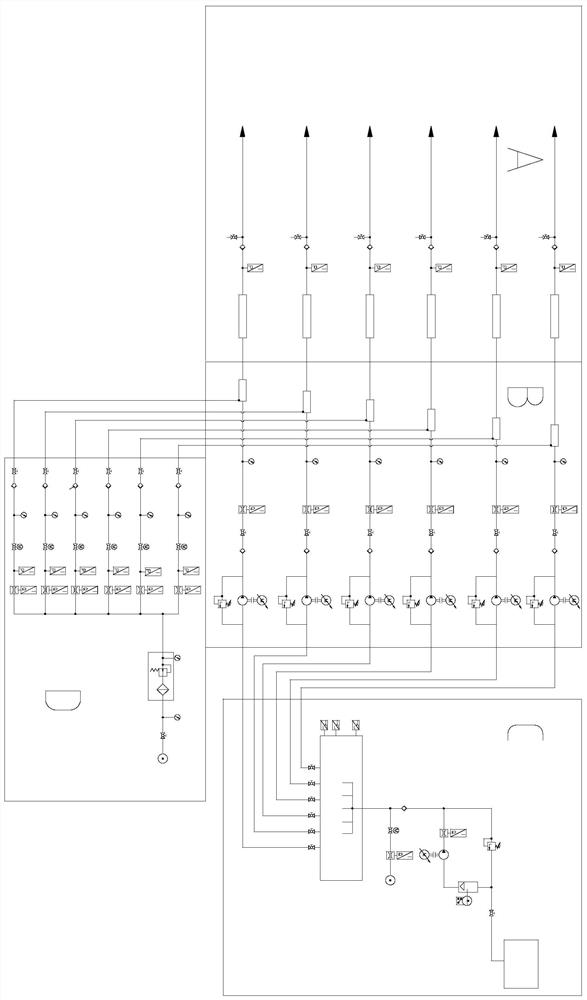

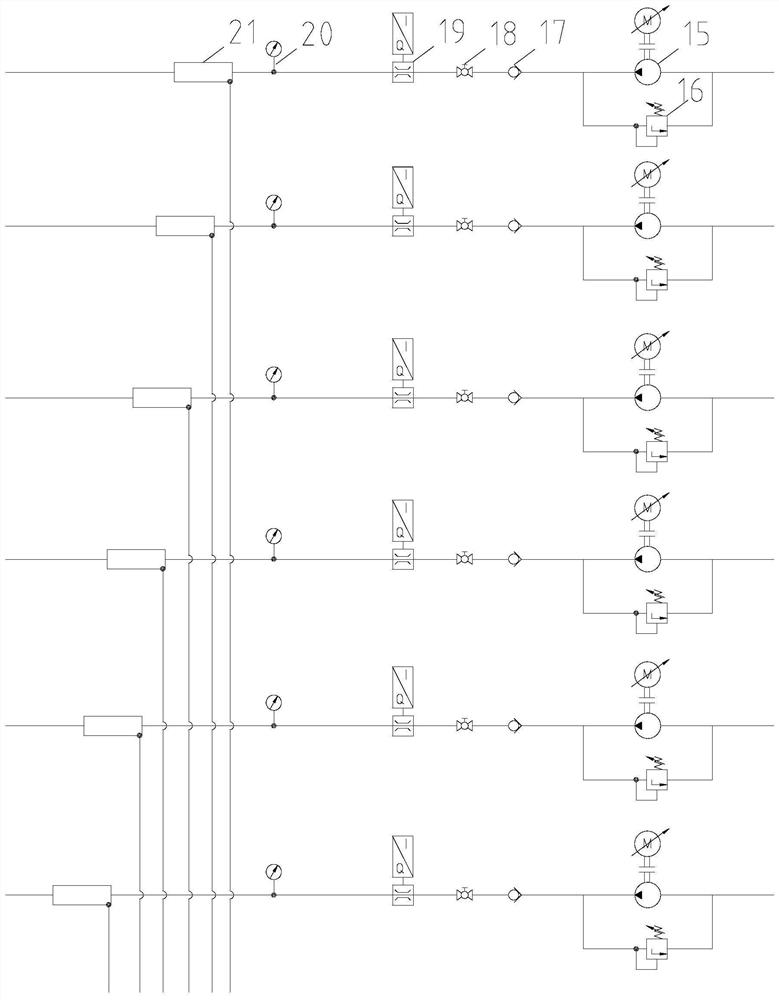

[0053] Such as Figure 1-Figure 5 As shown, the earth pressure balance shield foam system includes a solution generation unit and a gas transmission unit, the output pipes of the solution generation unit and the gas transmission unit are connected to the foam generator 21, and the foam generator 21 is used to provide muck improvement required foam;

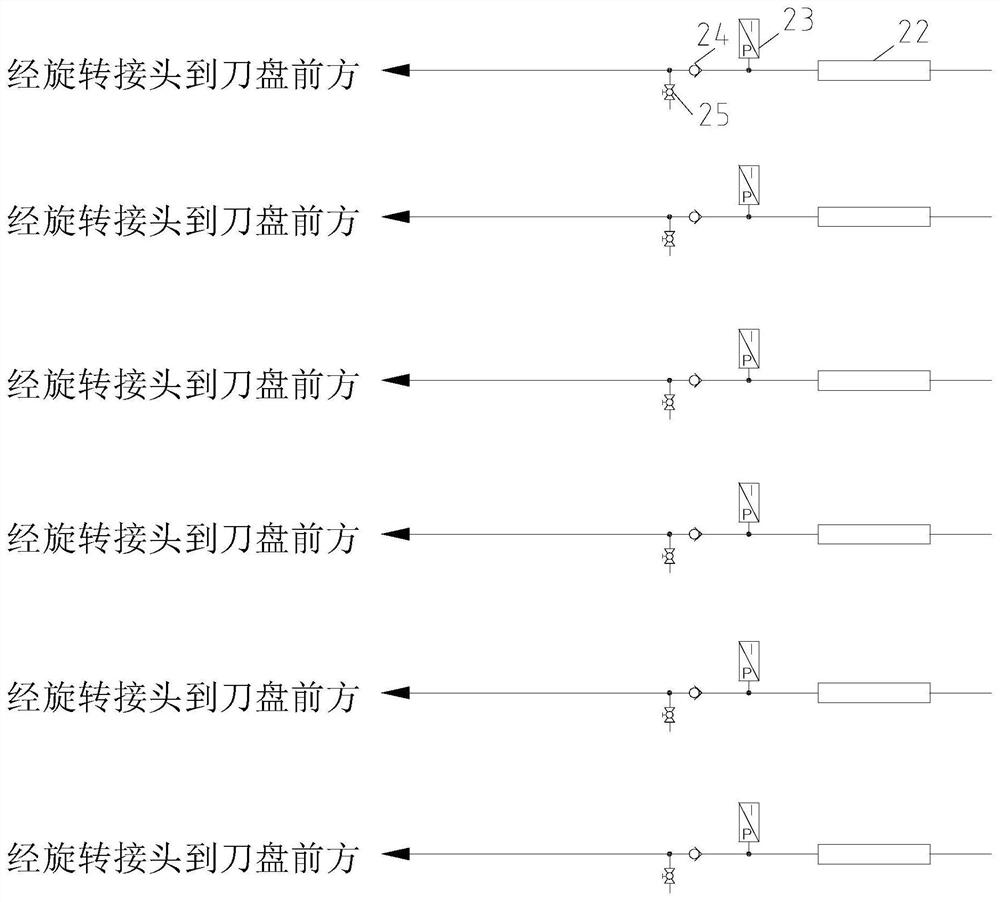

[0054] The foam generator 21 is connected to the foam pipeline, and the foam in the foam pipeline needs to be able to be sprayed to the front of the cutter head; further, the foam in the foam pipeline is directly and evenly sprayed to the front of the cutter head through the rotary joint, the pipeline and multiple nozzles in front of the cutter head On the palm surface, the muck cut by the cutter head is improved; the improved muck enters the soil cabin through the opening of the cutter head, and finally is output by the screw conveyor.

[0055] The solution generating unit comprises a container for containing the stock solution ...

Embodiment 2

[0058] In order to better realize storage, the container for containing the foam agent stock solution is a storage tank 1, and the bottom of the storage tank 1 is connected with the stock solution pipeline. The connection position between the stock solution pipeline and the storage tank 1 can make all the stock solution in the storage tank 1 flow out under the action of gravity. The installation position of the storage tank 1 is higher than the installation position of the first variable frequency screw pump 4 . The installation position of the mixing box 10 is higher than that of the second variable frequency screw pump 15 . Set up so that liquid flows by gravity to the variable frequency screw pump inlet.

Embodiment 3

[0060] The stock solution pipeline includes four sections, the four sections are respectively the first stock solution section, the second stock solution section, the third stock solution section and the fourth stock solution section; the second stock solution section and the third stock solution section are arranged between the first stock solution section and the fourth stock solution section. Between the stock solution pipe sections, the second stock solution pipe section and the third stock solution pipe section are arranged in parallel.

[0061] The second raw liquid pipe section is set as an overflow section, and a first safety overflow valve 5 is installed on the second raw liquid pipe section. The first safety overflow valve 5 can ensure the normal operation of the raw liquid pipeline and avoid damage to the first variable frequency screw pump 4 due to excessive pressure. When the outlet pressure of the first variable frequency screw pump 4 exceeds the safety pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com