High-flux droplet array rapid preparation device based on spray assistance

A preparation device and droplet technology, which is applied in the field of high-throughput droplet array rapid preparation device, can solve the problems of difficult sample addition and control operations, short storage time, expensive processing equipment, etc., and achieve the controllability of composition and spatial distribution Good, collection and long-term preservation of simple, good accessibility effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

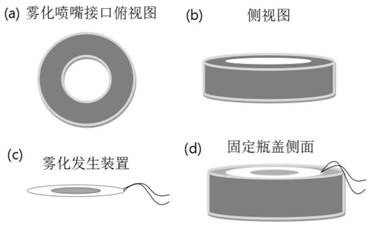

[0062] In this embodiment, the droplet generation and collection device consists of an atomization inlet, a sedimentation channel, a sedimentation pattern mask (that is, a mask with a pre-designed sedimentation pattern) and a collection interface (that is, a droplet collection interface) It consists of four parts.

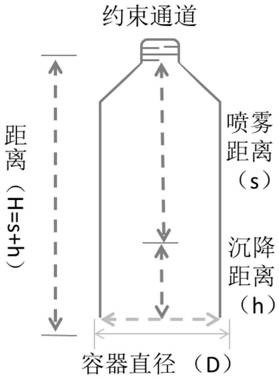

[0063] Such as figure 1 As shown, the atomization generating device preferably adopts an ultrasonic atomizing sheet. In order to form a uniform and rapid droplet array, it is more appropriate to select a spray outlet aperture of about 5-9 microns. It is embedded in the bottle cap with screw cap, and the screw cap on the bottle cap is fixed and sealed with the settling channel to prevent the leakage of spray droplets. In this embodiment, the settling channel can be made of glass or plastic transparent material, so as to facilitate the observation of the aerosol settling process. The priority is to choose the common 500ml plastic bottle for modification, which is l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com