Steel slag and blast furnace water slag composite powder as well as preparation method and application thereof

A technology of blast furnace slag and composite powder, which is applied in the field of comprehensive utilization of solid waste, can solve the problems of increasing the amount of steel slag, and achieve the effects of increasing later strength, improving hydrophobicity and cohesion, and improving strength and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

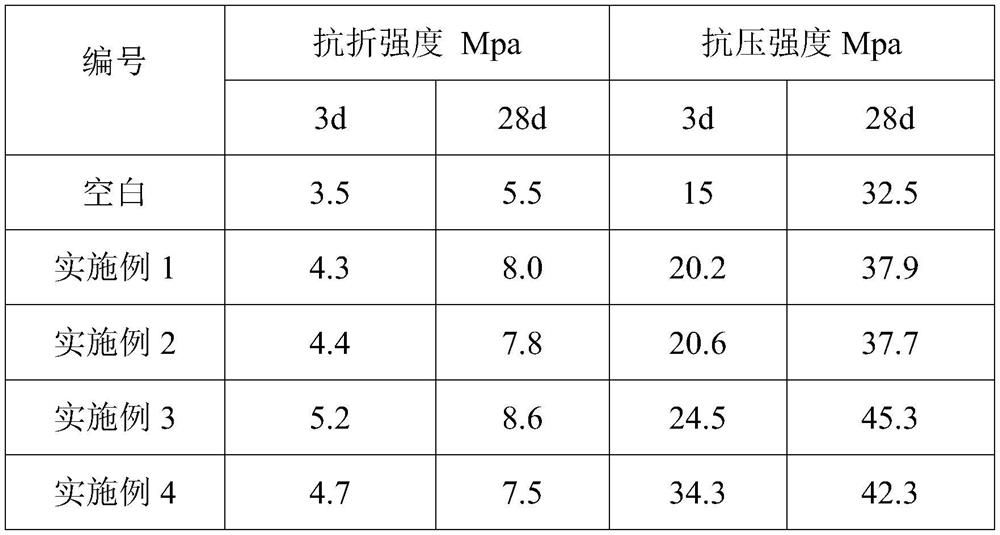

Examples

Embodiment 1

[0019] A method for modifying steel slag and blast furnace slag composite powder. The raw materials are: 38% steel slag, 57% blast furnace slag fine powder, 3% calcium oxide, 0.05% tetrahydroxyethylethylenediamine, and 0.6% sodium hydroxide , water glass 1.3%, hydroxypropyl methylcellulose 0.01%, tetrahydroxypropyl ethylenediamine 0.04%, and a total amount of 100%; the percentages are mass percentages.

[0020] According to the formula ratio, mix steel slag, blast furnace water slag fine powder, calcium oxide, tetrahydroxyethylethylenediamine, sodium hydroxide, water glass, hydroxypropyl methylcellulose and tetrahydroxypropylethylenediamine evenly to obtain product1.

Embodiment 2

[0022] A method for modifying steel slag and blast furnace slag composite powder. The raw materials are: 44% steel slag, 51% blast furnace slag fine powder, 2.4% calcium oxide, 0.07% tetrahydroxyethylethylenediamine, and 0.7% sodium hydroxide , water glass 1.8%, hydroxypropyl methylcellulose 0.01%, tetrahydroxypropyl ethylenediamine 0.02%, and a total amount of 100%; the percentages are mass percentages.

[0023] According to the formula ratio, mix steel slag, blast furnace water slag fine powder, calcium oxide, tetrahydroxyethylethylenediamine, sodium hydroxide, water glass, hydroxypropyl methylcellulose and tetrahydroxypropylethylenediamine evenly to obtain product2.

Embodiment 3

[0025] A method for modifying steel slag and blast furnace slag composite powder. The raw materials are: 42% steel slag, 54% blast furnace slag fine powder, 2% calcium oxide, 0.06% tetrahydroxyethylethylenediamine, and 0.5% sodium hydroxide , water glass 1.4%, hydroxypropyl methylcellulose 0.01%, tetrahydroxypropyl ethylenediamine 0.03%, and a total amount of 100%; the percentages are mass percentages.

[0026] According to the formula ratio, mix steel slag, blast furnace water slag fine powder, calcium oxide, tetrahydroxyethylethylenediamine, sodium hydroxide, water glass, hydroxypropyl methylcellulose and tetrahydroxypropylethylenediamine evenly to obtain Product 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com